How To Design Aggregate Plant

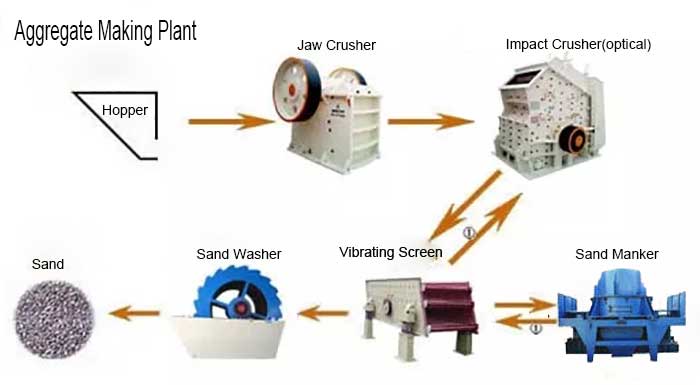

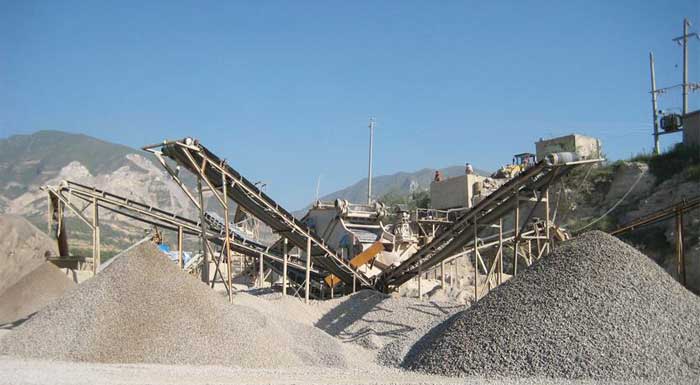

Sandstone production line is also called Aggregate Plant. It is a special designed plant for producing sand and stone for construction. The finished products include various sizes stone and artificial sand, which is equivalent to the combination of stone crushing line and sand making line.

Firstly, large stone is fed into jaw crusher evenly by vibration feeder through hopper for primary crushing , and the crushed stone is fed into crusher equipments (cone crusher or impact crusher) by belt conveyor for secondary crushing. The crushed stone is fed into the aggregate screens by belt conveyor for screening. The finished sand (undersize material) is sent by the belt conveyor to the aggregate washers for cleaning, and then clean final products will be discharged.

Larger stone (oversize material) is sent to sand making machine (vertical impact crusher) by belt conveyor for fine crushing. The finely crushed stone is fed into the fine aggregate screens for screening again. This forms a closed circuit manifold cycles. So how to design aggregate plant?

We suggest 5 factors to consider when designing a aggregate making plant:

1. Make waste-free output possible

To ensure that each size of the materials can be produced in accordance with demand, the extra size material can be made sand at any time, improve the efficiency of resource utilization.

2. Reasonable process flow

Material from primary crushing to secondary crushing to screening, different types of equipment may be used at different stages. In the design, sufficient adjustment space should be reserved so that operators can adjust on demand.

3. Reserve feed hopper for cone crusher

Reserving a buffered hopper to ensure uniform feeding and full feeding for cone crusher, which is beneficial to both the efficiency of cone crusher and the protection of bowl liner and mantle (Cone Crusher Common Problems).

4. Pay attention to the quality of sand and stone

Good quality sandstone is gradually replacing poor quality sandstone. In addition, with the continuous improvement of building standards, the demand for fine sandstone is also increasing.

5. Pay attention to environment protect

Environmental protection is becoming more and more important. Sandstone projects that do not focus on environment will be banned or eliminated.

Four Steps To Build Aggregate Production line

Four Steps To Build Aggregate Production line Mobile Crushing Plant For Recycled Aggregate

Mobile Crushing Plant For Recycled Aggregate 1000T/H Limestone Aggregate Production Line

1000T/H Limestone Aggregate Production Line A 800 TPH Sand Making Plant Details

A 800 TPH Sand Making Plant Details