Top 8 Types of Desanders and Their Features

A desander is a device used to remove impurities and sand particles, widely applied in water treatment, wastewater treatment, petroleum industry, and metallurgical industries. Based on different working principles and structural features, desanders can be classified into the following types: centrifugal desander, settling desander, filter desander, air flotation desander, and screen desander etc.

1. Centrifugal Desander

Centrifugal desander utilizes centrifugal force to separate impurities and sand particles from water. It typically consists of an inlet, a rotating separation zone, and an outlet. When water flows through the inlet into the rotating separation zone, the centrifugal force generated by the high-speed rotation of the device forces impurities and sand particles outward to the inner wall, while clean water flows out through the outlet.

Features: include large processing capacity and effective separation, making them suitable for handling high concentrations of impurities and sand particles.

Subtype: Cyclone Desander

Specifically designed based on centrifugal sedimentation and filtration principles. Effective for solid-liquid separation, widely used in water source heat pumps, food, medicine, and mineral processing to remove sand from river/well water and industrial wastewater.

2. Screw Desander

Screw desander is a type of screw sand-water separator. It is an integrated equipment for the separation and lifting of organic sand in wastewater. It can separate particles with a particle size ≥ 0.2mm, achieving high separation efficiency.

The installation inclination angle of the screw desander is between 20° and 30°. The sand-water mixture enters the tank from the inlet pipe. The heavier particles in the mixture (such as sand grains) settle at the bottom of the spiral trough due to their own weight. Pushed by the spiral, the material moves upwards along the bottom of the inclined U-shaped trough. After leaving the liquid surface, it continues moving upward for a distance. The water content in the sand grains gradually drains back into the tank through the gaps in the spiral trough, and the sand grains gradually become dewatered. At the discharge outlet, the dried sand falls into other conveying devices by its own weight. The clarified water continuously flows out from the outlet pipe. This achieves the purpose of sand-water separation.

Features: screw desanders adopt a shaftless spiral design, featuring lightweight construction, compact structure, reliable operation, and easy installation.

3. Inclined Plate Desander

Inclined plate desander causes sand and gravel in water to settle through the obstruction effect of inclined plates. Settled sand is discharged through a sand outlet, while water flows directly through the inclined plate zone and filter plate.

Features: Inclined plate desanders are widely used in various water supply projects, especially for sources with high sand content such as tube wells, open wells, and infiltration galleries. They can be directly installed on pipelines to remove fine sand particles from water, preventing sand accumulation in water transmission pipelines, with a removal rate exceeding 90%.

4. Settling Desander

Settling desander is a device that uses sedimentation for solid-liquid separation. It typically comprises a long, narrow trough with slow internal water flow velocity. As water passes through the trough, impurities and sand particles gradually settle to the bottom under gravity, forming sediment, while clean water flows out from the top of the trough.

Features: simple design and easy operation, making them suitable for treating low concentrations of impurities and sand particles.

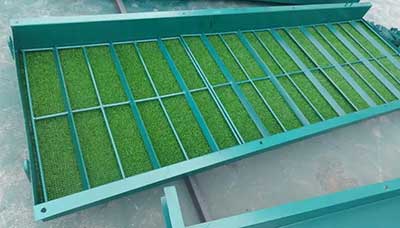

5. Vibrating Desander

Vibrating desander is a device used to treat drilling fluids, primarily for separating solid particles from drilling mud.

Features: vibrating desanders are widely used in petroleum drilling and horizontal directional drilling for solid-particle separation in drilling fluids. They offer large processing capacity and high efficiency, suitable for solid-particle separation in various drilling operations.

6. Filter Desander

Filter desander uses filter media to remove impurities and sand particles from water. It generally consists of filter media, a filter cartridge, and a filter tank. When water passes through the filter cartridge, impurities and sand particles are blocked by micropores on the cartridge, while clean water flows out from the other side.

Features: Characteristics of filter desanders include excellent filtration effectiveness and stable operation, making them suitable for handling fine impurities and sand particles.

7. Air Flotation Desander

Air flotation desander utilizes the principle of bubble adsorption and sedimentation to separate solids from liquids. It typically consists of a flotation zone, a sedimentation zone, and a bubble generator. When water passes through the bubble generator, bubbles attach to the surfaces of impurities and sand particles, reducing their density and causing them to float to the water surface to form floating sludge, while clean water flows out from the bottom of the sedimentation zone.

Features: characteristics of air flotation desanders include effective treatment and stable operation, making them suitable for handling fine impurities and sand particles.

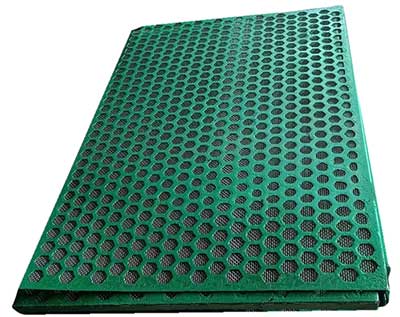

8. Screen Desander

Screen desander uses a screen mesh to filter impurities and sand particles from water. It typically consists of a screen mesh, an inlet, and an outlet. When water flows through the screen mesh, fine apertures on the mesh block impurities and sand particles, while clean water flows out from the other side.

Features: convenient operation and easy maintenance, making them suitable for handling fine impurities and sand particles.

Different types of desanders possess unique characteristics and application scopes. Selecting the appropriate desander type based on specific application requirements can enhance the removal efficiency of impurities and sand particles, improve production efficiency, and reduce operational costs.

Types of Aggregate Washers & Their Features

Types of Aggregate Washers & Their Features Coal Dewatering Screen | Working Principle | Features

Coal Dewatering Screen | Working Principle | Features Screw Conveyor Features | Working Principle and Types

Screw Conveyor Features | Working Principle and Types 6 Types of Rock Drill Bit Materials and Their Features

6 Types of Rock Drill Bit Materials and Their Features