14 Cone Crusher Common Problems

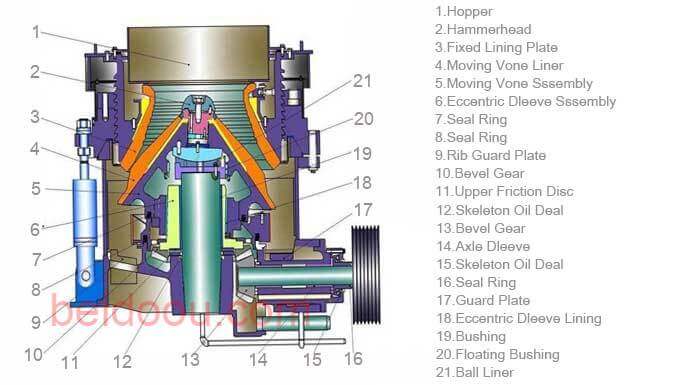

Cone crusher has high crushing ratio, high efficiency, low energy consumption, uniform product size, suitable for medium crushing and fine crushing of various ores and rocks. In the cone crusher working process will encounter a variety of problems, So, we provides 14 common fault causes and solutions!

1. The oil temperature is too high.

Cause: The quality of the oil is poor or the oil is insufficient; the bearing is damaged; the ambient temperature is high, there is no cooling water or the cooling water pressure is low; the cooler is clogged.

Solution: change oil or refuel; change bearings; supply cooling water or increase the pressure of cooling water; clean the cooler.

2. Oil temperature and pressure rise.

Cause: The tubing or oil groove is clogged and the safety valve is faulty.

Solution: Stop the machine, check and repair.

3.Oil pressure is low after oil pump is started

Cause: The oil temperature is low; the pipe is blocked or the pump is running abnormally.

Solution: Heat to increase oil temperature; repair pipe or oil pump.

4.Oil contain lots of fine mud and impurities.

Causes: failure of sealing dustproof device; water shortage caused by blockage or leakage of water pipe.

Solution: Sealing or cleaning after shutdown, replacing new oil.

5.There is water in the oil

Causes: water enters the lean oil station; the cooler leaks, and the water pressure is greater than the oil pressure; water supply too much or the return pipe is blocked.

Solutions: Clean oil tank and replace oil; repair leakage or replace cooler, reduce water pressure, clean oil tank and replace oil; adjust water supply or clean water return pipe, clean oil tank and replace new oil.

6.The vibration of cone crusher is too strong.

Causes: Cone crusher base is loosening; Difficult-to-break materials enter the crushing chamber, leading to blockage; parts break or wear; poor lubrication makes the spindle tightened by bushing.

Solutions: fastening bolts, pouring; controlling the type of feed, strictly forbidding the entry of non-fragments; strictly controlling the amount of feed; stopping the machine to check accessories; replacing damaged parts, repairing oil pumps and pipelines.

7. The crushing cone rotates very high.

Causes: oil shortage or dust in oil between spindle and bushing; insufficient clearance of tapered bushing; wear or manufacturing reasons of bowl bearing bush, contact surface deep to inner circle, conical body sinking.

Solutions: overhaul or replace bushings, spindles, etc., and find out the causes of oil shortage, eliminate it; adjust bushing clearance; re-scrape, and meet the requirements.

8. The sudden speed of the moving cone accelerates.

Cause: the sinking of moving cone or the damage of spherical thrust bearing; the movement of conical bushing upstream causes insufficient clearance with the spindle.

Solution: Adjust the gap.

9. Non-uniform rotation of transmission shaft

Causes: serious wear or damage of gears; damage of connection keys; breakage of spindle.

Solutions: stop and replace gears, and make meshing clearance meet the requirements; change the connection keys; change the spindle, strengthen iron removal work.

10. Make splitting sounds.

Cause: the lining plate is loose; the moving cone or fixed cone lining plate is not round and causes impact.

Solution: Stop the machine to check the screw tightening and zinc layer falling off.

11. The coupling rotates and the crusher does not move.

Causes: transmission coupling or gear key break; spindle break.

Solution: disassembly and inspection for renewal; disassembly and inspection for renewal.

12. The drive shaft produces a strong knock.

Causes: Unqualified installation of bevel gears, poor meshing, excessive clearance, too large axial clearance of transmission shaft or gear damage.

Solution: Correct meshing clearance or replace gear.

13. The supporting ring jumps.

Cause: Non-fragments fall into the crushing chamber, and the main shaft is easy to break.

Solution: Strengthen iron pick-up or install iron remover.

14. The size of ore discharging increases.

Cause: Serious wear of liner.

Solution: adjust the outlet, reduce the size of the outlet, and replace the lining plate.

What is Cone Crusher | How To Select Cone Crusher Correctly

What is Cone Crusher | How To Select Cone Crusher Correctly 10 Steps To Install Cone Crusher

10 Steps To Install Cone Crusher 8 Tips Help To Maintain Cone Crusher

8 Tips Help To Maintain Cone Crusher Jaw Crusher VS Cone Crusher | Which Is The Better Crusher

Jaw Crusher VS Cone Crusher | Which Is The Better Crusher

I need help please can you help me the code of terex cone crusher na solutions

ok Mr HASSAN RAMADHAN RASHIDI, i will ask our manager contact you for the cone crusher details.

our crusher making aggregate too much flaky , please can we adjust . base course production have problem .

Our osborn cone runs for an hour then the hydraulic pumps jst trip then the whole crusher stops, when we check for trouble shooting on our plc theres no fault written on our pc.

Hi. I need help. Do you know how can KDC32 cone crusher consume too much hydraulic oil ISO150, please? We are adding hydraulic oil each 2nd. month, but after another 2 months hydraulic oil tank is empty again and the other tank with ISO68 oil spills over now (it is mixed with missing hydraulic oil probably). How is this mixing possible inside the crusher?

David Masek

1.what causes low oil pressure on a 1650 gyratory crusher?.

2.How does oil lubricate bushes and eccentric wear plate in the 1650 gyratory crusher?.

3.How do i eliminate spillages in a 1650 gyratory crusher?.