Top 10 Tips for Shank Adapter Fractures

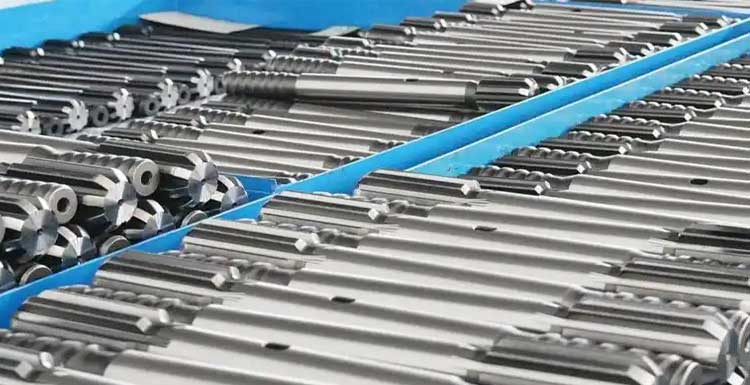

The shank adapter (shank end), serving as the core component of hydraulic rock drills for transmitting rotational force and impact energy, must withstand complex loads transferred by the impact piston and rotation motor during operation. Primary causes of shank adapter fracture include the following 10 tips:

Improper Operation

When operating a rock drill, improper techniques—such as using an oversized drill steel causing tool jamming or deflection, or uneven force application leading to unbalanced tool wear—can result in shank end fracture.

Loose Bolts

Under the rock drill’s impact frequency of 40–110 times per second, loose bolts induce machine oscillation. This subjects the shank end to instantaneous multiplied stress, critically affecting other components.

Guide Sleeve Wear

If the clearance between a worn guide sleeve and the shank end exceeds 1mm, the front end of the shank end initiates intense vibration.

Insufficient Lubrication

Inadequate lubrication of the shank end guide sleeve causes excessive heat, accelerating sleeve wear and increasing crack risks in the shank end.

Pressure Mismatch

Low thrust pressure or “dry drilling” traps stress waves, generating superposition that induces violent friction and fracture at weak points. Excessive thrust pressure bends the shank end, causing rapid fracture under impact.

Incorrect Installation

Misalignment between the rock drill’s mounting on the feed beam and the shank end/stabilizer creates radial forces, leading to fracture under uneven loads.

Poor Drill Bit Quality

Substandard drill steel fails under its own weight or lateral loads during drilling, contributing to shank end breakage.

Unreasonable Drill Bit Design

Drill bits that are excessively long, brittle, or soft directly cause shank end fractures.

Inadequate Maintenance

Prolonged use without proper upkeep accelerates deflection and uneven wear, triggering shank end failure.

Drill Bit Usage Timeout

Long term use of drill bits can lead to deformation, wear, fatigue, and other problems, which can easily cause the phenomenon of broken shank adapter.

Drill Bit | Drill Rod | Connection Sleeve | Shank Adapter Functions

Drill Bit | Drill Rod | Connection Sleeve | Shank Adapter Functions 15 Troubleshooting and Solutions for Hydraulic Rock Drill

15 Troubleshooting and Solutions for Hydraulic Rock Drill 10 Types of Rock Drill Bits | How To Choose Drill Bits

10 Types of Rock Drill Bits | How To Choose Drill Bits Rock Drill | Working | Types | How To Choose Rock Drill

Rock Drill | Working | Types | How To Choose Rock Drill