15 Troubleshooting and Solutions for Hydraulic Rock Drill

Hydraulic rock drills, critical equipment in tunneling and rock mining operations, are highly regarded for their efficiency. However, prolonged contact with hard rock inevitably leads to various failures. Below, we explore fifteen common faults and their corresponding maintenance solutions.

I. Failure of Impact Mechanism to Strike

① No hydraulic oil pressure issues

If there is no hydraulic oil pressure in the hydraulic rock drill, it is recommended to check the relevant control mechanisms and systems of the mining equipment to determine the problem.

② Uneven or bent tightening of the tightening screw

If the tightening screw is found to be unevenly tightened or bent, the tightening screw can be removed first to release the tension. Subsequently, tighten the screws one by one according to the prescribed torque to solve the problem.

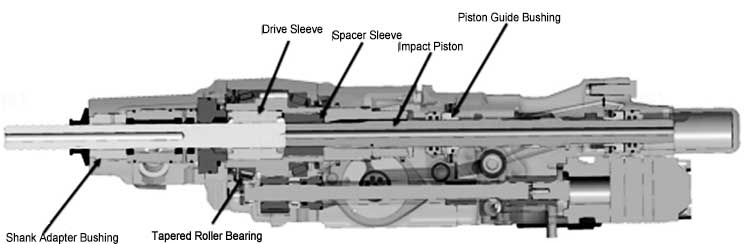

③ Piston scratch

If the piston is scratched, the rock drill on the drilling device should be replaced immediately and the damaged machine should be sent to the repair room for repair. Next, remove the tail of the machine and try to manually push and pull the piston to observe if its movement is smooth. If the piston movement is obstructed, it may indicate that the piston and sleeve have been scratched, and the sleeve needs to be replaced. Depending on the situation, it is necessary to decide whether to replace the piston.

④ Scratch on the distribution valve

If after the above experiment, it is found that the piston can move smoothly but the distribution valve cannot move, the distribution valve should be removed for detailed inspection.

II. Abnormal Vibration in Impact Inlet Hose

If after the above inspection of the distribution valve, it is found that the hydraulic rock drill has abnormal vibration in the inlet hose during the impact process, it may be caused by scratches or damage to the distribution valve. At this point, it is necessary to further check the working status of the distribution valve to ensure its normal operation.

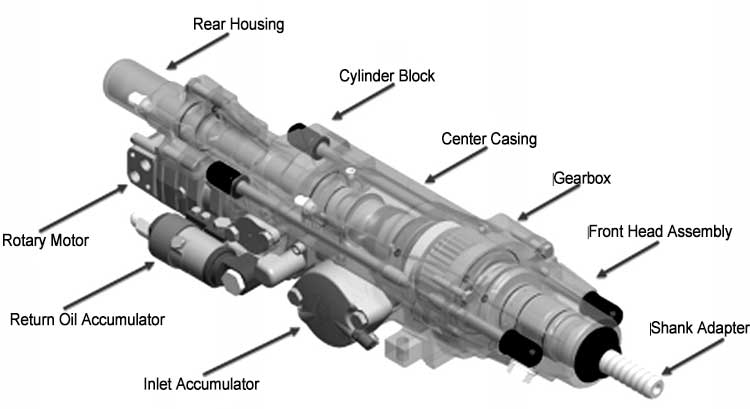

① Energy storage device inspection

If there is abnormal vibration in the oil inlet hose during the impact process of the hydraulic rock drill, and the inspection of the distribution valve is unsuccessful, it may be a problem with the accumulator. At this point, the air pressure inside the accumulator should be checked, and if necessary, it should be refilled. If the accumulator cannot maintain the required pressure, it may be due to air leakage at the nozzle or damaged diaphragm, which needs to be replaced in a timely manner.

III. Reduced Impact Efficiency

Verify system oil pressure via gauge and control mechanisms.

Inspect impact mechanism if systems are functional.

IV. Severe Oil Leakage at Drill Head

Caused by failed piston seals or shank adapter rebound absorber seals.

Solution: Replace seals or send for repair.

V. Irregular Rotation

Cause: Lubrication system failure.

Solution: Confirm lubricant pressure and flow rate.

VI. Failure to Rotate

Cause: Defective rotation motor or hydraulic system fault.

Solution:Check motor pressure; replace motor if needed. Inspect hydraulic circuits.

VII. Motor Functional but Shank Adapter Stalls

Cause: Worn drive components.

Solution: Replace the driver.

VIII. Water Leakage

Cause: Failed seals in water supply assembly.

Solution: Replace seals.

IX. Abnormal High Temperature (>80°C)

Cause: Insufficient lubrication.

Solution:Check lubricator oil level, dosage, and flow. Ensure gearbox is filled with grease.

X. Hydraulic Oil Leak Between Front End and Shank Adapter

Cause: Worn/broken piston Stripper seals.

Solution: Replace seals.

XI. No Impact Force

Causes & Solutions:

Worn shank/adapter threads → Replace.

Jammed distributor valve → Clean/replace.

Cracked shank adapter bushing/impact piston face → Replace parts.

XII. Water Leakage (Repeated)

Cause: Damaged water seal.

Solution: Replace seal.

XIII. Fractured Impact Piston Face

Causes & Solutions:

Poor lubrication → Maintain 35–40 drops/minute.

Uneven side-rod tension → Tighten rods sequentially to 300 N.m every 8 hours.

Insufficient quality of impact piston → Check if the hardness of the piston is 3-5 HRC higher than that of the drill tail.

XIV. Broken Side Rods

Causes & Solutions:

Uneven/infrequent tightening → Adhere to 300 N.m every 8 hours.

Fatigue fracture → Replace immediately.

XV. Severe Vibration in Impact Return Hose

Cause: Low nitrogen pressure or damaged accumulator diaphragm.

Solution: Replace/recharge accumulator.

Rock Drill | Working | Types | How To Choose Rock Drill

Rock Drill | Working | Types | How To Choose Rock Drill 10 Types of Rock Drill Bits | How To Choose Drill Bits

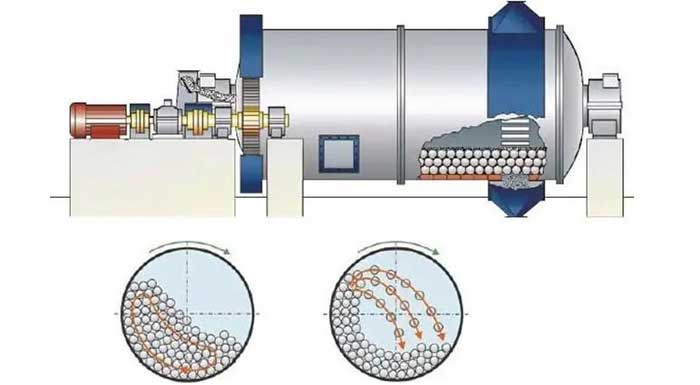

10 Types of Rock Drill Bits | How To Choose Drill Bits 14 Types of Ball Mill Troubleshooting and Solutions

14 Types of Ball Mill Troubleshooting and Solutions How To Solve Drill Rod Jamming Faults [ Top 6 Tips ]

How To Solve Drill Rod Jamming Faults [ Top 6 Tips ]