The Secrets of Making Charcoal from Sawdust

The yield ratio of charcoal from sawdust varies depending on factors such as raw material quality, carbonization process, and equipment performance. Generally, it takes approximately 3-4 kg of sawdust to produce 1 kg of charcoal.

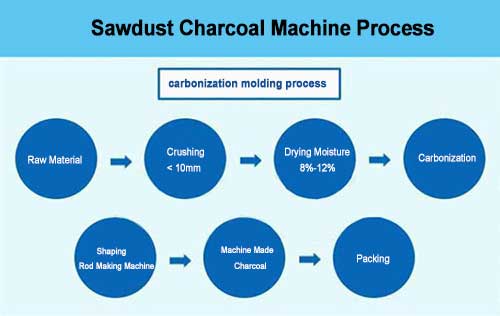

The Principle of Sawdust Charcoal Production

The process of transforming sawdust into charcoal primarily involves the pyrolysis of organic substances like lignin and cellulose within the sawdust. During this process, moisture, volatile matter, and impurities are removed from the sawdust, resulting in high-quality charcoal.

While charcoal production traditionally consumes large amounts of timber and energy, utilizing sawdust charcoal machines allows for the efficient use of waste materials like sawdust, simultaneously reducing wood consumption. The fundamental principle of sawdust charcoal machines is similar to traditional charcoal making, but differs in specific steps:

- Raw Material Preparation: First, raw materials like sawdust undergo crushing to ensure a particle size within 10mm. If the raw material contains large impurities or has high moisture content, drying is also required to control the moisture content below 12%.

- Briquetting: The processed sawdust is then shaped using a briquette machine (or rod-making machine), which applies high temperature and pressure to form the sawdust into solid rod-shaped fuel.

- Carbonization: The formed briquettes are fed into the sawdust charcoal machine for carbonization. Subjected to high temperatures, the volatile matter is driven off the sawdust rods, ultimately forming mechanized charcoal.

Temperature is the most critical factor affecting charcoal quality, typically requiring carbonization temperatures above 400°C. Choosing the appropriate heating method (common ones include direct and indirect heating) is crucial. The carbonization time is usually over 12 hours. The moisture content and wood species of the raw material also influence the final charcoal quality.

Factors Affecting Charcoal Yield Ratio

- Raw Material Quality: The moisture content, ash content, and volatile matter in the sawdust directly impact charcoal yield. Generally, sawdust with low moisture and low ash content is easier to convert into high-quality charcoal.

- Carbonization Process: Parameters like carbonization temperature, duration, and atmosphere significantly affect yield. Optimizing the carbonization process can increase yield while ensuring charcoal quality.

- Equipment Performance: Advanced carbonization equipment and well-established production processes ensure the stability and continuity of charcoal yield.

How to Increase Charcoal Yield ?

- Select High-Quality Sawdust: Using sawdust with low moisture and low ash content as raw material helps improve yield.

- Optimize the Carbonization Process: Adjusting factors like temperature, time, and atmosphere to find the optimal carbonization conditions enhances yield.

- Regular Equipment Maintenance: Maintaining the charcoal machine in good working condition ensures process stability and continuity.

Frequency Asked Questions About Sawdust Charcoal Machine

Is it necessary to add adhesive to produce charcoal with sawdust?

No need, Sawdust is formed into briquettes through high-temperature and high-pressure compression in briquetting machines, requiring no additional adhesive. Sawdust itself contains lignin and will naturally form solid shapes after high-temperature and high-pressure processing.

Sawdust processing does not require further crushing with a crusher machine. But, humidity of sawdust must be maintained within 5%–10% before briquetting. Excessively wet sawdust should first be dried to the optimal humidity range using a dryer. Thus the proper drying ensures effective briquetting and prevents issues during subsequent carbonization.

How many tons of sawdust can produce one ton of charcoal?

When the humidity of raw sawdust is less than 12%, 2.5-3 tons of sawdust can produce one ton of charcoal.

How To Select Sand Making Machine?

How To Select Sand Making Machine? Wet Sand Making VS Dry Sand Making

Wet Sand Making VS Dry Sand Making A 800 TPH Sand Making Plant Details

A 800 TPH Sand Making Plant Details VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications