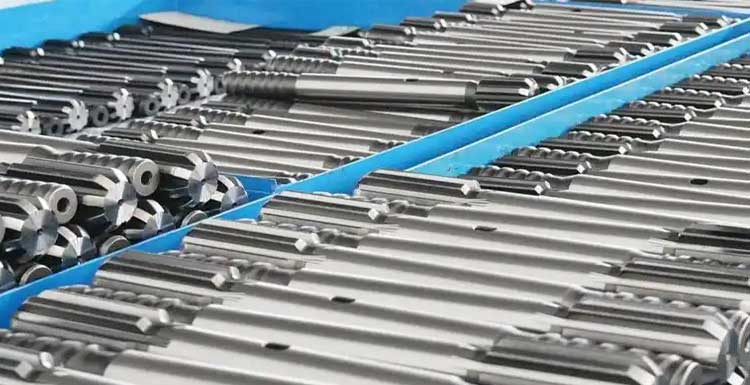

How To Solve Drill Rod Jamming Faults [ Top 6 Tips ]

During the operation of rock drills, drill rod jamming is a common and quickly solvable problem. Different solutions can be taken to address the cause of drill pipe jamming:

1. Excessive Dust Accumulation: Excessive dust in the working environment.

Solution: Thoroughly clean internal dust, especially around the bit and jammed rod sections. Always power off the equipment before cleaning.

2. Prolonged Usage Duration: Failure to replace the drill rod as required.

Solution: If the jammed rod is irreparable, replace it with a new one.

3. Misaligned Bit Position: The drill bit position has deviated and has not been adjusted correctly.

Solution: For functional but mispositioned rods causing reduced drilling efficiency, readjust the bit to its precise position.

4. Loose Drill Rods: Improperly secured rods tend to vibrate and jam.

Solution: Ensure rods are firmly fixed before operation to prevent vibration-induced jamming.

5. Rock Cuttings Clogging: Drilling operations generate significant cuttings. Untimely removal leads to borehole blockages, hindering rod advancement.

Solution: Continuously clear cuttings during drilling, particularly near the borehole end. Installing water flushing systems cleans borehole walls, preventing cumulative blockages.

6. Drill Rod Fracture: Substandard rod quality or extended service life increases fracture risk, causing jamming.

Solution: Prioritize high-quality rods and routinely inspect for deformation/excessive wear. Replace defective rods immediately to avoid fractures.

Rock drill rod jamming is a common problem in rock drilling operations, and there are various solutions available. When using a rock drill, operators should pay attention to the fixation, cleaning, and maintenance of the drill rod, quickly solve the problem of drill rod jamming, and improve work efficiency.

Drill Bit | Drill Rod | Connection Sleeve | Shank Adapter Functions

Drill Bit | Drill Rod | Connection Sleeve | Shank Adapter Functions 10 Types of Rock Drill Bits | How To Choose Drill Bits

10 Types of Rock Drill Bits | How To Choose Drill Bits 15 Troubleshooting and Solutions for Hydraulic Rock Drill

15 Troubleshooting and Solutions for Hydraulic Rock Drill Top 10 Tips for Shank Adapter Fractures

Top 10 Tips for Shank Adapter Fractures