6 Types Sandstone Aggregate Screening Equipments

Screening equipments are mainly divided into 2 types: Vibratory Screens and Stationary Screens.

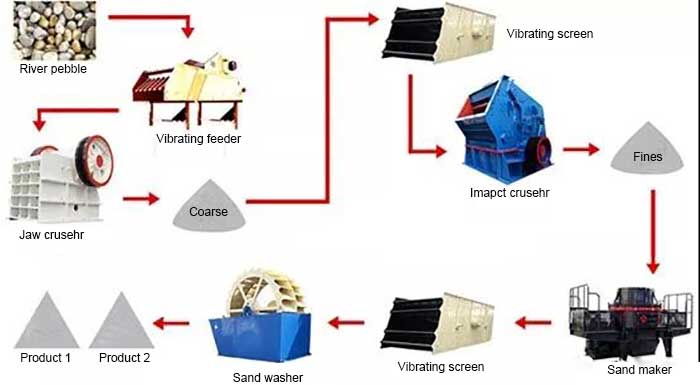

Vibratory screens are widely used in sandstone and aggregates production line.

Stationary screens contain: scalping screens and bar screens. They are generally used in crushing workshop or natural aggregates production system to isolate oversize stones, but the screening efficiency is very low, only 50%~70%. Due to the absence of vibration, the materials block the screen hole easily, it takes time and effort to clean the screen plates, which affects the production. Therefore, only when the amount of sand and gravel in the quarry is largeer and the oversize stones are more, the stationary screens will be used.

The following list the 6 hot types vibratory screening equipments commonly used in sand aggregate production line:

1. Eccentric Vibratory Screen

Features: The eccentric axis directly drives the screen frame to move in a trajectory with an amplitude equal to twice the eccentricity in the vertical direction. Strong structure, constant amplitude and large and constant vibration force when feed rate changes. Screen hole is not easy to plug; bearing structure is complex, inertia is large, because of incomplete balance when working, it is easy to cause simultaneous vibration of buildings.

Scope of application: Screen hole 100 ~ 250mm, often used in pre-screening stage, or the first screening stage of sand and gravel. Nowadays, inertial vibratory screen is mostly used instead.

2. Uniaxial Vibratory Screener

Features: The working principle is the same as pure inertial vibratory screen. But in structure, the pulley is concentric with the transmission shaft, and the pulley center remains fixed during the working process, and the motor runs smoothly. Large amplitude; large exciting force and high screening efficiency can be obtained; simple structure and easy manufacture, no need for accurate balancing exciter; large amplitude during start-up and shutdown process through resonance zone, which is harmful to equipment and buildings.

Scope of application: It is suitable for screening medium and fine aggregates with continuous and uniform feeding.

3. Linear Vibratory Screen

Features: Two eccentric axes rotate in reverse synchronization, driving the screen panels to do linear vibration; the screen panels are in horizontal after installation, with large screen panel areas and strong amplitude, which is helpful to aggregate screening; complex structure, expensive price, high energy, and difficult amplitude adjustment. However, linear vibration screen structure is complex and the amplitude adjustment is difficult, which also cost much.

Scope of application: It is suitable for screening coarse, medium and fine aggregates. It can also be used as dewatering and desliming equipment in wet production.

4. Banana Screen

Features: The material moving speed decreases on the screens that with different inclination angles gradually, but the thickness of the material remains constant. Banana screen has high output, screen hole is not easy to clog, high production efficiency, simple installation and operation; however, It covers a large area and the structure of screen panel is complex.

Scope of application: It is suitable for screening fine aggregates with particle size < 25 mm.

5. High Frequency Screener

Features: High screening efficiency, small amplitude and high frequency.

Scope of application: It is suitable for screening materials with small particle size.

6. Circular Vibratory Screen

Features: Circular vibratory screen is a new type of multi-layer vibratory screen with circular motion. Circular vibratory screen is widely used in material screening in mining, building materials, transportation, energy, chemical industry and other industries. Structural reliability, strong exciting force, high screening efficiency, low vibration and noise, durable, easy maintenance.

Scope of application: Screening accuracy is high, material size can reach 500 mesh

What should be considered in selecting screening equipment:

1) The working area and passing capacity of screening equipment;

2) The size of the cutting chute matches the size of the vibratory screen surface properly to ensure the uniform distribution of aggregate.

3) Match the dust collector according to the amount of dust generated during screening.

4) Wear resistance of chute and hopper of vibratory screen and protection of noise pollution during material falling.

How To Improve Screening Efficiency Of Vibrating Screens

How To Improve Screening Efficiency Of Vibrating Screens 5 Types Crusher Equipments For Sand And Aggregate Production Line

5 Types Crusher Equipments For Sand And Aggregate Production Line 1000T/H Limestone Aggregate Production Line

1000T/H Limestone Aggregate Production Line Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Thanks for helping me understand that screens would be used to isolate oversized stones during the crushing process or the natural aggregate production process. I guess looking for various options that will be the most effective for the kind of material you are using will be important such as choosing between a compact screening plant or other types of them. In my opinion, it would definitely be for their own peace of mind and to save them from additional expenses if the equipment and tools they are using are going to be effective for the first time.