Four Steps To Build Aggregate Production line

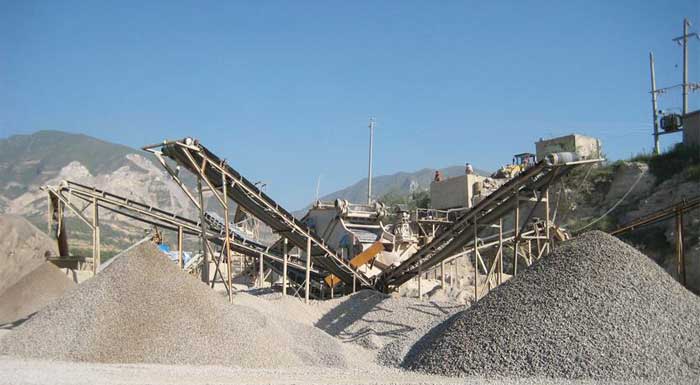

Aggregate production line is an important link in the development of modern aggregate mine. The aggregate production line consists of four systems: feeding system, crushing system, screening system and sorting system.

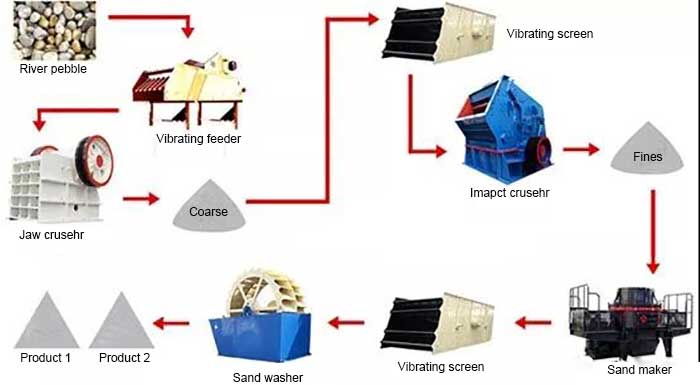

Aggregate Manufacturing Process

1. Pretreatment

In the pre-treatment stage of aggregate production, hammering is usually used to pre-crush the bulk materials in the sand and gravel aggregate, and sort the sundries which are not suitable for crushing, and remove waste wood, plastic and other sundries. in order to facilitate the next treatment process. And the first magnetic separation is carried out to remove the scrap iron in the aggregate.

2. Sand Making By Crusher

First of all, the raw material is crushed by a jaw crusher, the vibration feeder is fed evenly, and the jaw crusher is used to crush the large sand and gravel aggregate into a smaller particle size. The cracked materials are transported to the transfer reactor by the conveying belts. Then the sand maker can be used for fine crushing and shaping of the material to make the sand and gravel aggregate particle size uniform.

3. Primary Screening

In this stage, a circular vibrating screen is used to screen the coarse concrete aggregate into 0-40mm blocks and less than 5mm crushed materials. Among them, 5-40mm coarse aggregate can be directly used for c15-c20 concrete after being collected. Fine aggregate can be transported to the transfer station for the next process.

4. Secondary Crushing & Screening

In this stage, the fine aggregate can be comminuted again by ball mill. The secondary screening can divide the crushed aggregate into 5-20 mm high-quality recycled aggregate, which can be used for c25-c30 concrete. High quality recycled fine aggregate of 0.15mm-5mm and fine powder of less than 0.15mm can be separated by three times screening.

To configure a reasonable aggregate production line, we need to consider the actual site conditions, output, particle size, energy consumption and other requirements of users.

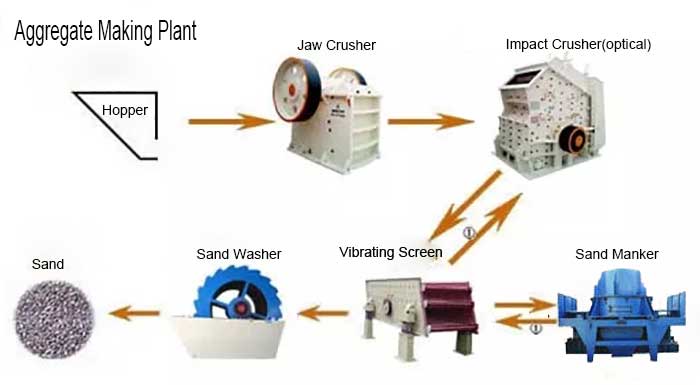

Common equipment combination forms of aggregate production line:

1. Jaw Crusher + Cone Crusher + Sand Making Machine + Auxiliary Equipment (feeder, conveyor, elevator, etc.);

2. Jaw Crusher + Impact Crusher + Sand Making Machine + Auxiliary Equipment;

3. Hammer Crusher + High Efficiency Fine Crusher + Impact Sand Making Machine + Auxiliary Equipment.

5 Types Crusher Equipments For Sand And Aggregate Production Line

5 Types Crusher Equipments For Sand And Aggregate Production Line 1000T/H Limestone Aggregate Production Line

1000T/H Limestone Aggregate Production Line 3 Million Granite Sand Making Production Line

3 Million Granite Sand Making Production Line How To Design Aggregate Plant

How To Design Aggregate Plant