What is Permanent Magnetic Drum Separator | How Does It Work

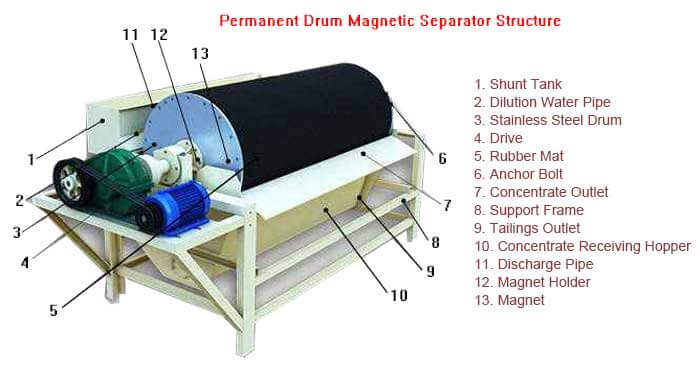

What is Permanent Magnetic Drum Separator

The permanent magnetic drum separator is suitable for the separation of fine-grained magnetic minerals in metallurgical mines and concentrators, or for the removal of mixed magnetic minerals in non-magnetic minerals.

The surface magnetic field intensity of the permanent magnetic drum separator is much higher than that of the ordinary permanent magnetic separator, which is easy to operate, manage and maintain. The processing capacity is usually 24T/H-240T/H.

How Permanent Magnetic Drum Separator Work

After the pulp flows into the tank through the ore feed tank, under the action of the water spray pipe, the ore particles enter the ore area in a loose state.

In the magnetic field, The magnetic ore particles are magnetically aggregated to form “magnetic clusters” or “magnetic chains”. The “magnetic clusters” or “magnetic chains” are magnetically moved in the slurry to move toward the magnetic poles and are adsorbed on the cylinder, and the non-magnetic minerals such as gangue adsorbed on the cylinder fall off during the overturning, and the “magnetic clusters” or “magnetic chain” adsorbed on the cylinder surface is the concentrate.

The concentrate will follow the cylinder to the weakest magnetic edge, and is discharged into the concentrate tank under the action of flushing water.

Under the action of pulp flow in the tank body, non-magnetic ore particles and weak magnetism ore particles flow into the tailing pipe from the tailing hole on the bottom plate. The pulp is fed continuously, and the concentrate and tailings are discharged continuously to form a continuous separation process.

Types & Features of Permanent Magnetic Drum Separators

According to the structure of the tank, the permanent magnetic drum separator can be divided into 3 types:

1. Downstream Type

The feeding direction of pulp is the same as that of the drum, the concentrate is discharged on the other side, and the tailings is discharged directly at the bottom, which is generally used for 6-0mm strong magnetic minerals.

Features: The downstream magnetic separator has a bigger processing capacity, which is suitable for the roughing and selection of coarse and strong magnetic materials, and can also work in series. When the amount of ore is large, the magnetic ore is easy to lose, so we should strengthen the operation management and control at a lower pulp level.

2. Countercurrent Type

The feeding direction of ore slurry is opposite to that of the drum. The concentrate is discharged from the feeding side, and the tailings are discharged from the other side. It is generally used in 0.6-0mm strong magnetic minerals.

Features: The countercurrent magnetic separator is suitable for the coarse and sweep separation of fine and strong magnetic minerals. The recovery is high, but the concentrate grade is low. Because the coarse material is easy to deposit and block the separation space, the countercurrent magnetic separator is not suitable for coarse materials.

3. Semi-Countercurrent Type

The feeding direction of half of the pulp is the same as that of the barrel, and the other half is the opposite. The difference with the downstream type is that the pulp rotates in a circle in the tank.

The slurry is washed loose by water to prevent inclusion, and the movement direction of pulp is consistent with the magnetic direction, which is conducive to the recovery of 0.5-0mm strong magnetic minerals.

Features: The semi-countercurrent magnetic separator can obtain high quality iron concentrate and better recovery.

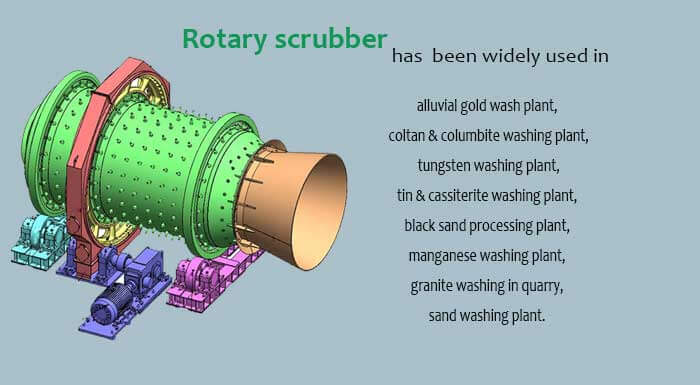

What is Rotary Scrubber and How Does It Work

What is Rotary Scrubber and How Does It Work What is Trommel Screen and How Does It Work

What is Trommel Screen and How Does It Work Silica Sand Washing Plant | Quartz Sand Processing

Silica Sand Washing Plant | Quartz Sand Processing Magnetic Minerals | How To Classify Magnetic Minerals

Magnetic Minerals | How To Classify Magnetic Minerals

I’m interested the Permanent Magnetic Drum Separator

iam interested in manganese ore dry magnetic separator