Mobile Crushing Plant For Recycled Aggregate

Mobile crushing plant is a new type of material crushing equipment with high performance and automation, which integrates crushing, screening and debris sorting in one unit. Mobile crushing plnat integrates the traditional fixed production line into a mobile platform, which makes it have better mobility, realize in-situ movement, turning, and self-walking in a short distance.

In addition, mobile crushing plant greatly shortens the project preparation time and solves the problems of production line layout, design, environmental protection, footprint etc. Which plays an important role in the construction waste process and recycled aggregate production.

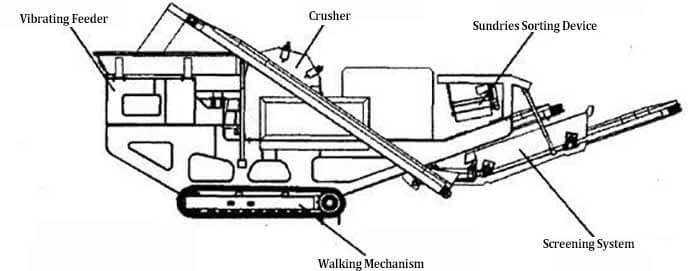

Mobile Crushing Plant Structure

Mobile crushing plant integrates vibrating feeder, crusher, screening system, sundries sorting device and transmission mechanism, and is equipped with a walking mechanism, which is a mobile production line. The structure is as follows:

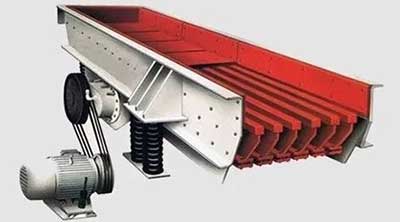

Vibrating Feeder

The vibrating feeder is used to feed evenly and improve the working conditions of the crusher. If the crusher is fed directly, it will have an impact on the working device of the crusher, making its structure discontinuous and easy to cause impact damage to the equipment.

Generally, the bar feeder is selected. Before the material is vibrated and slides forward into the crusher, the construction waste with smaller particles will fall from the gap between the bars and play the role of screening.

Crusher

The crusher is the core component of the mobile crushing plant, which is mainly responsible for crushing construction waste.

To ensure the performance of recycled aggregate, it is necessary to ensure that the particle size distribution of the crushed material should be uniform, so the crushing capacity, crushing efficiency and material quality of the crusher need to meet the needs.

Screening System

In order to ensure the quality of recycled aggregate after crushing, it is necessary to carry out secondary crushing if the particle size can not meet the requirements after primary crushing, so it is needed to add a screening system to screen the concrete blocks with larger particles and transport them back to the crusher for re-crushing.

At present, there are 2 kinds of commonly used vibrating screening equipment: linear vibrating screen and circular vibrating screen.

Walking Mechanism

There are 2 types of walking mechanism of mobile crushing plant: one is crawler type, the other is tire type.

Tire Walking Mechanism:

- High chassis, small turning radius;

- Easy to drive on the ordinary highway, can quickly enter the construction site;

- The equipment has high flexibility and saves time.

- The vehicle-mounted generator set can provide a continuous power source for the equipment.

Crawler Walking Mechanism:

- The center of gravity is low, walking smoothly;

- It has good adaptability to mountains and wetlands;

- Generally adopt full hydraulic drive system with large driving force and high reliability;

- The module assembly is adjustable and no additional traction equipment is required.

Sundries Sorting Device

There are more sundries in construction waste, such as scrap iron, wood, glass and waste plastic, especially more waste steel bar and waste iron wire in reinforced concrete, so it is necessary to install a sundries sorting device (iron remover) on the mobile crushing plant.

Recycled Aggregate From Construction Waste

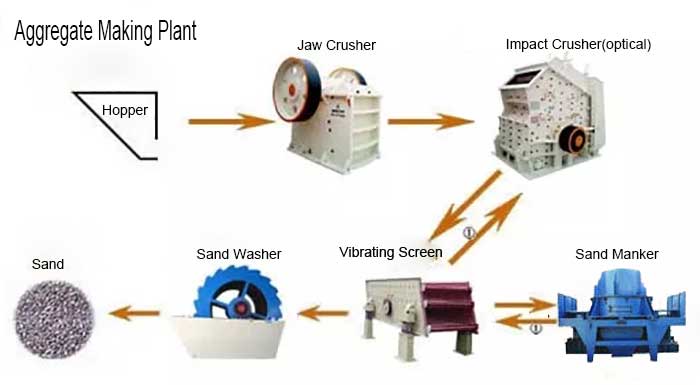

Recycled Aggregate From Construction Waste Four Steps To Build Aggregate Production line

Four Steps To Build Aggregate Production line How To Design Aggregate Plant

How To Design Aggregate Plant Industrial Solid Waste Recycling [ Tailings ]

Industrial Solid Waste Recycling [ Tailings ]

It’s interesting to know that the feeder should be fed evenly so that the working conditions of the crusher will improve. I think that applies to a mobile impact crusher as well when a company needs that kind of equipment. In my opinion, the property processes should definitely be followed to prevent any issues and incidents as well with the operator.

Hello, I`m looking for 2 mobile crusher & screening solutions.

1. Input construction waste (max feeding size 500 mm) output range of sizes 0-40 mm.

2. Input hard stones (like river pebbles), max feeding 300 mm, output range also range of sizes (0-40 mm).

Capacity: 100 TPH.

Thanks!

ok, Mr Tilmann Lattka, thanks for you inquiry the mobile crushing and screening solutions, we will contact you.