Recycled Aggregate From Construction Waste

What is Recycled Aggregate

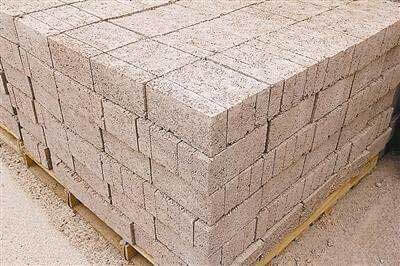

Aggregate made from the waste concrete in construction waste by crushing and screening is called recycled aggregate. The surface of recycled aggregate is rough, multi-angular, large specific surface area and large water absorption.

Therefore, when using recycled aggregate to prepare concrete, the unit water consumption is larger than that of ordinary concrete, and the slump loss of concrete is also large. The strength and elasticity of recycled aggregate concrete is equal to 2/3 of that of natural aggregate concrete.

Why To Recycle Construction Waste

Some studies have shown that for every 100 million tons of construction waste, 24.3 billion standard bricks and 36 million tons of mixture can be produced, 10 million cubic meters of soil can be reduced or natural sand and stone can be replaced, 2.7 million tons of coal can be saved, and the output value will be increased by 1.26 billion dollar, which create huge economic benefits.

In addition, in contrast to simple stacking and landfill, the recycling of construction waste can also reduce 50% of nitrous oxide, 99.3% of nitride and 28% of carbon monoxide emissions.

How Much Recycled Aggregate Made From Construction Waste

The conversion rate of construction waste into aggregate can reach 85%. One ton of construction waste can produce 0.85 tons of recycled aggregate, 0.01 tons of scrap steel, and the rest is other waste.

The selling price of recycled aggregate is about 60% of the natural sand and gravel materials, which can effectively reduce more than 40% of the construction cost and greatly save the cost.

How To Process Construction Waste

- Pretreatment: construction waste is pretreated first, including (optional) using hydraulic hammer to reduce large pieces of material, sorting to remove large debris, cutting too long steel bar, preventing damage to the conveyor belt, etc.

- Crushing: jaw crusher and impact crusher are used to crush the raw materials, this process can break the construction waste and separate the steel bar quickly.

- Iron Removal & Screening: iron metals such as steel bars in the broken construction waste are separated by the iron remover, and the sand and stone materials are formed into different specifications of finished products through vibrating screens.

- Grinding: if the finished product required is a powder with smaller particle size, a mill can be used to further process the broken construction waste.

How To Choose Construction Waste Processing Plant

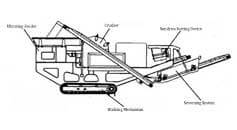

Fixed Sand Plant or Mobile Sand Plant, which is better?Compared with the fixed production line, the mobile crushing plant has become an ideal choice because of its advantages such as :

- No need for foundation and supporting construction;

- It can move the station quickly, fit for the narrow working face, reduce the transportation cost;

- It can be combined and matched flexibly under different working conditions to reduce investment cost;

- The equipment operation and maintenance is simple, and the investment cost of personnel is reduced;

- Able to complete mining, crushing and shipping in one operation, providing more production options.

Mobile Crushing Plant For Recycled Aggregate

Mobile Crushing Plant For Recycled Aggregate Industrial Solid Waste Recycling [ Tailings ]

Industrial Solid Waste Recycling [ Tailings ] Industrial Solid Waste Recycling [ Waste Rock ]

Industrial Solid Waste Recycling [ Waste Rock ] Industrial Solid Waste Recycling [ Slag ]

Industrial Solid Waste Recycling [ Slag ]