Feeder Machine Types | How To Choose A Feeder Equipment

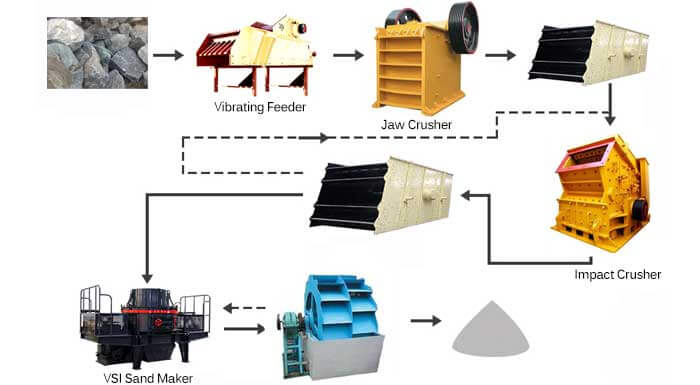

Feeder machine is a kind of feeding equipment which can feed bulk and granular materials from the stock bin to the receiving devices evenly, regularly and continuously. Which has been widely used in cement, mining, metallurgy, coal, chemical industry, ceramics, grain, electric power and other industrial and mining enterprises.

Feeder machine is the most ideal equipment to realize production automation. The feeder machines can not only be used with electronic scales or microcomputers, but also can work alone for feeding. The common types of feeder machine are as follows:

10 Types of Common Feeder Machine

Vibrating Feeder

When vibrating feeder is working, the vibrating motor drives the eccentric shaft or eccentric block to drive, and the centrifugal force produced by the rotation of the eccentric block is used to make the screen box and vibrator move in a continuous circle or approximate circle, and the bulk and granular materials from stock bin are fed into the receiving device uniformly, regularly and continuously .

Vibrating feeder is widely used in crushing and screening equipment of coal mine, mineral processing, chemical industry and mills etc. Usually suspended under the stock bin by a spring, the feeder trough can be arranged horizontally or with an angle of no more than 10°.

Belt Feeder

Belt feeder is the same as that of belt conveyor in structure, but the roller space of belt feeder is smaller to bear the pressure of materials in the silo. Guide baffles are arranged on both sides of the conveyor belt to prevent spreading. The belt speed < 0.5 m/min. The feed rate can be adjusted by changing the belt speed or the height of the outlet baffle.

Belt feeder has the advantages of large bearing capacity and short length, so it is also a kind of economical feeding equipment. The feed ore size suitable for belt feeder is less than 350mm and the belt speed is below 0.3m/s generally. Belt feeder is mainly used in ore buffer bin discharge after coarse crushing, ore feeding of medium/fine crushers or screening equipment, discharge of powder bin.

Plate Feeder

Plate feeder is suitable for short distance transportation and can bear heavy working load, including 3 types: heavy, medium and light. The maximum ore size of heavy plate feeder can reach more than 1000mm. The plate feeder is mainly used for coarse crushing ore feeding, ore buffer bin drainage after coarse crushing, and coarse ore heap discharge.

Plate feeder can be installed horizontally or tilted, with a maximum upward inclination of 20°. It is suitable for materials with loose density less than 1200kg/m³, block weight less than 140kg and temperature below 350℃.

Chute Feeder

Chute feeder is suitable for the ore feeding of medium-sized materials, the maximum particle size can reach 450mm, and the ore feed can be adjusted by adjusting the eccentricity of the eccentric wheel of the transmission mechanism. The width of the trough body of the chute feeder is 2-2.5 times of the maximum particle size of the ore feed, which is mainly used for the feeding of jaw crusher and bulk lime in the preparation of lime milk.

The most common chute feeder size is 980*1240mm, and its feed size is 0-350mm, which is suitable for the feeding equipment of 400*600 jaw crusher.

Pendulum Feeder

Pendulum feeder is suitable for short distance transportation and high specific gravity materials with a particle size of 35 – 100mm. Pendulum feeder is not suitable for conveying dry powder materials, otherwise dust pollution and outlet blockage will occur.

Pendulum feeder is mainly used as the feeding equipment of the belt conveyor when collecting ore in the ball mill, and the feed particle size is generally less than 25mm, which belongs to intermittent feeding.

Disk Feeder

Disk feeder is a kind of continuous volume feeding equipment composed of driving device, feeder body, metering belt conveyor and metering device, which makes use of the fluidity of materials. The material is scraped from the container to the receiving equipment through a rotating disc and an adjustable scraper, which is suitable for all kinds of non-viscous and not very good fluidity -20mm fine materials.

Disk feeders are divided into open type and closed type. Generally, the open type is adopted, and the closed type is used only when the content of fine particles of the material is high.

Screw Feeder

Screw feeder can be installed in the lower part of the silo and is suitable for horizontal, vertical or inclined conveying. The material flow is controlled and adjusted uniformly and continuously by changing the spiral speed. The screw feeder is easy to feed non-viscous powdery, granular and small particle materials evenly to the receiving equipment from the silo and other storage equipment.

Screw feeder has the features of conveying, sealing, homogenizing and stirring. It is a common equipment in cement raw meal homogenization and silo sealing feeding. There are many types of screw feeder, such as solid screw, belt screw, variable pitch screw, conical screw and so on.

Impeller Feeder

Impeller feeder is composed of a group of blades installed on the shaft and the outer sealing shell. Driven by the motor, the impeller on the spindle is driven by the reducer to drive the material from the upper silo through the impeller groove to feed out evenly. The feeding capacity is changed by adjusting the speed of the impeller.

Impeller feeder has good tightness, avoids environmental pollution, and is suitable for the transportation of loose non-viscous dry materials and small bulk materials with good fluidity.

Scraper Feeder

Scraper feeder is composed of many scrapers fixed between two chains with a certain distance between them. The scraper moves along the slot bottom, which can be used for horizontal transportation or inclined transportation. When transporting upward along the incline, the inclination of the material layer shall not exceed 25 °, and when transporting downward, the inclination shall not exceed 20 °.

The working principle and traction parts are the same as the scraper conveyor. Scraper feeder can realize closed and multi-point feeding, which is suitable for materials with less powder or granule, grindability and stickiness.

Electromagnetic Vibratory Feeder

Electromagnetic vibratory feeder uses the electromagnetic vibratory exciter as the vibration source to drive the hopper, which has the features of small amplitude, high frequency, slow conveying speed. Electromagnetic vibratory feeder is a new type of quantitative feeding equipment, which can meet the requirements of continuous production.

The maximum ore feeding particle size of electromagnetic vibratory feedercan reach 500mm, it is widely used for ore feeding of medium and fine crushing equipment and screening equipment, ore discharge of ore bin, etc.

How To Choose A Suitable Feeder Machine

The following factors must be taken into account when choosing a suitable feeder machine:

- 1. The feeder machine capacity should be matched with the system, and the purchase cost, operation cost and maintenance cost are reasonable.

- 2. The feeder machine is reliable and durable, the operation is stable, and the probability of sudden failure in work is little.

- 3. The service life of the parts of the feeder machine is long, so the maintenance times and equipment shutdown period should be reduced maximumly.

- 4. For auxiliary equipment, the procedures of standardization and serialization of spare parts should be high, versatility and interchangeability should be strong, and the metering unit and voltage level should meet the prescribed requirements.

- 5. The performance, structure, external dimension, quality and strength of the feeder machine are suitable for the plants.

- 6. The protection level of the feeder should meet the provisions of the safety regulations, and should be safe to use and maintain.

8 Tips Help To Choose A Suitable Screw Conveyor

8 Tips Help To Choose A Suitable Screw Conveyor Vibrating Feeder Installation & Operation & Troubleshooting

Vibrating Feeder Installation & Operation & Troubleshooting VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications Jig Machine | 4 Types of Jigger Machine|How To Choose

Jig Machine | 4 Types of Jigger Machine|How To Choose

Thank you for sharing your thoughts. I truly appreciate your efforts and I am waiting for your further post

thanks once again.