Industrial Solid Waste Recycling [ Tailings ]

Source of Tailings

Tailings is one of the products in the mineral processing process, and it is the part with the lowest content of useful target components. Unlike the waste rock from metal and non-metal mines, tailings generally come from tailings reservoirs or concentrators, which are the waste materials left after metal ore processing.

According to the mineral processing process, tailings can be divided into: gravity separation tailings, magnetic separation tailings, flotation tailings, chemical dressing tailings, electric separation and photoelectric tailings. At present, the tailings after magnetic separation and gravity separation are mostly used in the sand and gravel aggregate industry, but the tailings after flotation can not be used to produce sand and gravel aggregates.

Use of Tailings

(1) Recycled Aggregate

For tailings, many people know that it can be processed into recycled aggregate. Bridge building materials contain special tailings, which can be soaked under the high corrosion of seawater for more than 100 years.

(2) Concrete Fine Aggregate

Tailings can be used for low strength commercial concrete (C15, C20) or asphalt concrete. As the fine aggregate of concrete, there are regulations on the particle size of tailings, because coarse sand will make concrete dry and viscous; ultra-fine sand not only makes concrete very easy to separate, but also requires a large amount of water, thus increasing the amount of cement.

(3) Building Materials

Common tailings building materials include glass-ceramics, building ceramics, tailings cement, cast stone products, glass products, tailings fertilizer and lime-sand bricks (unfired bricks) and so on.

(4) Reclamation and Establishment of Ecological Areas

At present, there are many successful cases in the reclamation of tailing ponds, the cultivation of crops and the establishment of ecological parks. Various countries have issued technical specifications for mine ecological environment protection and restoration, which have laid a solid foundation for future tailings reclamation.

(5) Recovery of Valuable Ingredients

There are a variety of valuable metals and minerals in the tailings that have not been fully recovered, such as copper, cobalt, silver, sulfur, platinum and so on.

Sand Making From Tailings

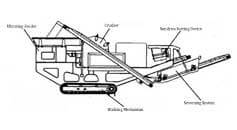

Fixed or mobile sand plant can be selected for tailing sand making, and the commonly used equipment includes jaw crusher, impact crusher, cone crusher, hammer crusher, vibrating screen, vibratory feeder, etc.

Case 1: 100T/H Tailings Sand Making Line

- Capacity: 100t/h

- Finished Product: ≤ 5mm for the construction of high-speed railway

- Core Equipment: vertical shaft impact crusher 1 unit, circular vibrating screen 1unit

Case 2: 50-60T/H Iron Tailings Mobile Sand Plant

- Raw Material: iron tailings

- Output: 50-60 T/H

- Usage: supply mixing station

- Core Equipment: tire mobile crusher plant

Case 3: 250 T/H Tailings Construction Waste Crushing Plant

- Raw Materials: industrial tailings, construction waste

- Finished Product: dry mixed sand slurry, high quality aggregate

- Capacity: 250T/H

- Core Equipment: PEW jaw crusher, PFW impact crusher, HPT multi-cylinder hydraulic cone crusher, VSI5X impact crusher, vibrating screen, vibratory feeder, iron remover, dust collector, sorting screen, screw conveyor, belt conveyor.

Industrial Solid Waste Recycling [ Waste Rock ]

Industrial Solid Waste Recycling [ Waste Rock ] Industrial Solid Waste Recycling [ Slag ]

Industrial Solid Waste Recycling [ Slag ] Recycled Aggregate From Construction Waste

Recycled Aggregate From Construction Waste Mobile Crushing Plant For Recycled Aggregate

Mobile Crushing Plant For Recycled Aggregate

Tailings are solid waste arising from mineral processing. This type of waste can cause severe damage to the environment during stockpiling as a result of the leaching of something harmful into the ecosystem. Gold deposit of ductile shear zone type is an important type of gold deposit, and the recycling of its tailings has been challenging researchers for a long time.