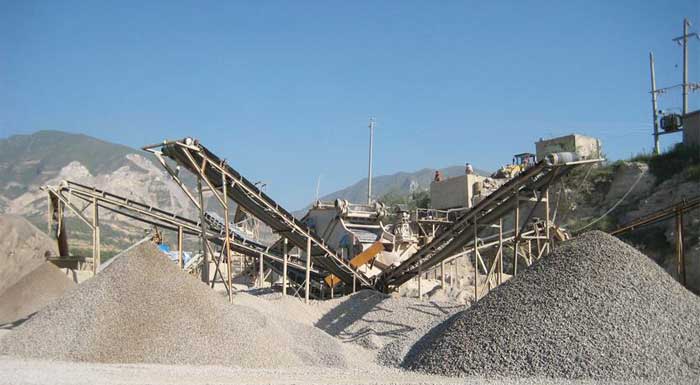

1000T/H Limestone Aggregate Production Line

Limestone is a kind of carbonate sedimentary rock and consist of more than 50% calcium carbonate. Limestone is a building material with great commercial value, widely distributed.

Limestone aggregate production line is very common, and the output varies from several hundred tons per hour to several thousand tons per hour. In this article, takes the production line of 1000t/h as an example to describe the equipments selection and manufacturing process.

Limestone Aggregate Project Overview

- 1.Production Capacity: 1000t/h aggregate.

- 2.Finished Product: 0.075-4.75mm, 4.75-15mm, 15-31.5mm aggregate.

- 3.Raw Materials Features: limestone, clay content is large.

- 4.Aggregate Quality: The quality of aggregate meets the requirements of GB/t14685-2011.

- 5.Environmental Protection: Dust emission concentration ≤ mg/Nm³, effluent treatment and waste solids management up to standard.

Main Equipments Selection

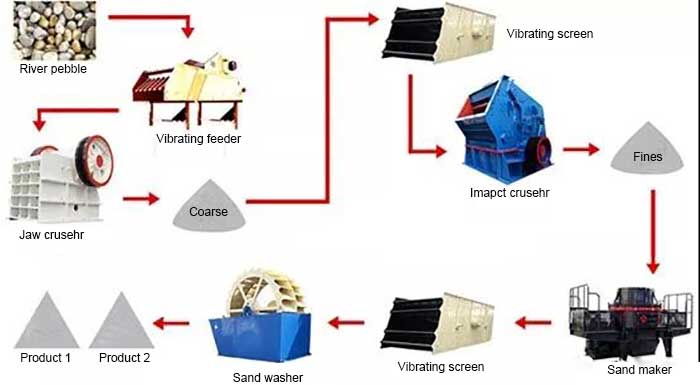

Limestone aggregate production line can be simply summarized as crushing, screen washing, sludge wastewater treatment and aggregate storage, the main equipments are as follows:

| Number | Equipmentst | Specification | Quantity |

| 1 | Gyratory Crusher | PXZ-1216, 200T/H | 1 |

| 2 | Plate Feeder | B2400*7000, 500T/H | 1 |

| 3 | Pre Vibrating Screen | 3YK3073, 650T/H | 2 |

| 4 | Standard Cone Crusher | PYS-BC2136, 600T/H | 2 |

| 5 | End Cone Crusher | PYS-DC2117, 600T/H | 2 |

| 6 | First Vibrating Screen | 3YK3673, 600T/H | 4 |

| 7 | Second Vibrating Screen | YK3060, 300T/H | 4 |

| 8 | Third Vibrating Screen | YK2052, 250T/H | 4 |

| 9 | Double Spiral Washer | 2LX1300, 150-200T/H | 4 |

| 10 | Hydrocyclone Group | FX350*4 | 2 |

| 11 | Linear Vibratory Screen | Z1848, 150T/H | 2 |

| 12 | Thickener | Ø32M | 1 |

| 13 | Filter Press | 15T/H | 3 |

1. Rough Crushing Equipment

Generally, coarse crushing equipment used in aggregate production is rotary crusher, jaw crusher and impact crusher. According to the production capacity (coarse crushing > 1200t/h), raw materials contain more soil and the market demand for aggregate products, usually, coarse crushing equipment is the rotary crusher.

2. Medium/Fine Crushing Equipment

Medium/Fine crushing equipment generally refers to cone crusher and impact crusher. Cone crusher is mainly suitable for crushing rocks with high hardness and high abrasiveness index, and the product powder is less. Impact crusher is mainly suitable for crushing rocks with medium or low hardness and abrasiveness index, and the products have more powder materials.

3. Screening & Washing Equipment

Aggregate screening equipment generally adopts linear vibrating screen or circular vibrating screen. Linear vibrating screen is suitable for small size screening and small output production, and can be used for water containing material dewatering. The circular vibrating screen has the advantages of high screening efficiency and large processing capacity, which is suitable for large-scale production.

When the circular screening equipment is equipped with a pressure water spray system, it can be used as a aggregate washing equipment. For the 0 ~ 4.75mm products, the spiral sand washing machine or bucket wheel sand washing machine can be used to wash the mud powder and stone powder to get the machine-made sand.

4. Waste Water & Solid Mangement

The sludge containing wastewater can only be discharged after treatment. This aggregate production line selects hydrocyclone groups, thickener and filter presses to treat the wastewater and sludge, avoiding the mud waste water covers a large area and the sedimentation tank is difficult to clean.

Limestone Aggregate Manufacturing Process

Limestone ore is roughly broken by the rotary crusher and stored in the intermediate material storage shed, and then transported to the pre screening workshop. The materials larger than 31.5mm after pre screening are fed to the standard cone crusher for medium crushing; the materials of 4.75-31.5mm and the materials after medium crushing are sent to the aggregate screening workshop for primary washing.

When raw material soil content is small, the materials < 4.75mm after pre screening are also sent to the screening and washing workshop for screening and washing. When the raw materials soil content is large, the materials < 4.75mm are transported to the waste material storage shed, and then used for the reclamation cushion after mining.

1. Aggregate Screening & Washing

Aggregate screening & washing consists of three-stage wet screening. Each stage of wet screening & washing is completed by the vibrating screens and the high-pressure spray equipment installed on each screen.

The materials from the pre screening and medium/fine crushing pass the primary screening, materials > 31.5mm will be returned to the medium/fine crushing workshops for crushing again. Materials < 4.75mm are sent to the double spiral sand washer together with the stone washing wastewater for washing. 4.75-31.5mm aggregates are transported to the secondary and tertiary vibrating screens for further screening & washing.

2. Aggregate Washing & Waster Management

Materials < 4.75mm together with stone washing wastewater will be fed into sprial sand washer for solid/liquid separating. The separated wastewater will be separated again by the hydrocyclone group. The separated machine-made aggregates will be delivered to the 0.075-4.75mm storage yard.

The sewage after separation is concentrated in the thickener, and the upper clear water of the concentrated liquid flows into the clean water tank, which is recycled by the clean water pump. The lower mud is sent to the filter presses for press filtration through the middle buffer tank and the slurry pump.

3. Aggregates Storage and Sale

The washed aggregate shall be stored in the open air. At least 2 vibrating feeders and belt conveyors shall be set under each aggregate pile to control the grading of aggregate when sold.

Four Steps To Build Aggregate Production line

Four Steps To Build Aggregate Production line 5 Types Crusher Equipments For Sand And Aggregate Production Line

5 Types Crusher Equipments For Sand And Aggregate Production Line 3 Million Granite Sand Making Production Line

3 Million Granite Sand Making Production Line Mobile Crushing Plant For Recycled Aggregate

Mobile Crushing Plant For Recycled Aggregate

Iam interested in that machine.

How much is a complete set?

ok sir, i will contact you about the aggregate making plant

We are looking for complete quotation for lime

Stone production line with capacity of 500 tons /day

Hello Mr Nabil Sarrouf,

Thanks for your inqyiry, we will contact you very soon by your email.