What Is Rock Gold Mine | Rock Gold Beneficiation Equipments

According to the laws of nature, gold mines can be divided into rock gold, sand gold, and associated gold. Rock gold is an important mineral for obtaining gold resources. Let’s learn together what is rock gold mines? What are the mineral processing equipment for rock gold mines?

What Is Rock Gold Mine?

Rock gold mine refers to the metallic minerals contained in gold mines, especially ores with higher grades of metallic elements. Gold minerals are closely associated with the main rocks present in ores, and their formation is related to the geological background of gold deposits, including tectonic background, rock types, and mineralization processes.

Gold is widely distributed in the Earth’s crust and ultimately forms rock gold deposits due to the triggering of underground hydrothermal activity, crustal deformation, or volcanic activity.

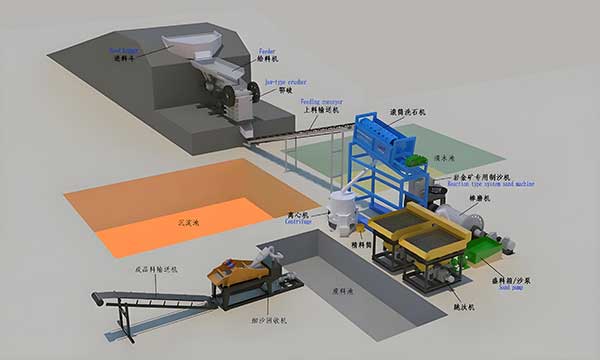

Types of Rock Gold Beneficiation Equipment

Usually, the beneficiation methods for rock gold include flotation, gravity separation, cyanide method, etc. Before mineral processing, it is necessary to crush and grind the gold ore. Therefore, rock gold ore beneficiation equipments usually include flotation machines, gravity separation equipments, cyanide equipments, crushing equipments, and grinding equipments.

1. Rock Gold Flotation Equipment

Flotation is one of the commonly used techniques for extracting gold from rock gold. During flotation, the slurry combines with chemicals and gases to create hydrophobicity between minerals, causing the selected minerals to adhere to bubbles. With the stirring of the flotation machine, they are scraped out by a scraper and become concentrate.

The commonly used rock gold flotation equipment includes mechanical agitation flotation machine and inflatable agitation flotation machine.

Mechanical Stirring Flotation Machine: This type of flotation machine is a self-priming flotation machine. During the operation, the slurry needs to be inflated and stirred by a mechanical agitator, without the need for an external aeration device. It can also self suction the slurry. The equipment in the operation room is horizontally configured, without the need for a return pump to transport the intermediate ore, effectively reducing the investment in infrastructure and some auxiliary equipment.

Inflatable Stirring Flotation Machine: This type of flotation machine relies on an external blower to complete inflation during operation, and then the agitator stirs the slurry. When the intermediate ore returns, it needs to be pumped.

2. Rock Gold Gravity Separation Equipment

Gravity separation of rock gold mainly utilizes the density difference between gold and other minerals to achieve separation. Gravity separation is more suitable for the separation of coarse-grained gold deposits, and for fine-grained gold separation, it is often used in combination with other process methods as a pre selection gold extraction process.

The commonly used gravity separation equipment includes: shaking table, jigs, spiral chutes, and centrifugal beneficiation machines.

Shaking Table: The suitable particle size range for rock and gold ore selection using a shaking table is 2~0.037mm. During operation, the motor drives the bed surface to move back and forth. Under the action of water flow, minerals are distributed in a fan-shaped pattern on the bed surface according to their different densities.

Jig Machine: suitable for selecting rock and gold ores within the range of 30 (20)~0.5mm. During operation, the pulsating vertical water flow of the equipment is used to loosen the minerals and sort them according to different densities. This method can effectively discard impurities such as surrounding rocks and inclusions, and improve the grade of gold ore.

Spiral Chute: The suitable particle size range for sorting rock gold particles is 2~0.074mm. During operation, a certain concentration of slurry is fed into the spiral surface for zoning based on the density difference of the ore. Minerals with high specific gravity are on the inner edge, those with low specific gravity are on the outer edge, and fine mud are on the edge. After several sections of spiral grading, concentrate, medium ore, and tailings can be selected separately.

Centrifugal Beneficiation Machine: Suitable for the recovery of fine gold particles below 0.2mm (0.074-0.10mm), commonly used for the recovery of placer gold mine or vein gold mine. The centrifugal beneficiation machine mainly relies on the centrifugal force generated by the rotating flow of the equipment to complete the separation.

3. Rock Gold Cyanide Equipment

According to different methods, it can be divided into two types of gold extraction methods: stirring cyanide and filtration cyanide.

Stirring Cyanide Method: Used for processing flotation gold concentrates or whole mud cyanide gold extraction, including zinc powder displacement (CCD and CCF) gold extraction method and carbon slurry (CIP and CIL) gold extraction method;

Infiltration Cyanide Method: Used for processing low-grade gold bearing oxidized ores, its gold separation process is based on the infiltration of cyanide solution through the ore layer to leach gold from the gold bearing ore.

The commonly used equipment for cyanide process in rock gold mines includes adsorption column, lean solution tank, lean solution pump, precious solution tank, carbon storage tank, acid washing tank, analytical column, electrolytic tank, desorption solution tank, air compressor, circulating pump, concentrator, zinc powder feeder, deoxygenation tower, filter press, slurry pump, etc.

4. Rock Gold Crusher

Crushing is an important step before rock gold enters mineral processing. After mining, the raw ore needs to go through a crushing process to achieve partial dissociation of mineral monomers or provide favorable conditions for monomer dissociation.

The crushing stage is to crush the gold ore to below 12mm to facilitate subsequent operations. The commonly used equipment in this process includes jaw crushers, cone crushers, circular vibrating screens, and linear vibrating screens. The core of the rock gold mine crushing equipment is a combination of jaw crusher and cone crusher. The former is responsible for coarse crushing, while the latter completes medium and fine crushing, which can efficiently process high hardness ores.

5. Rock Gold Grinding Machine

The grinding stage of rock gold mines often adopts a one-stage grinding or two-stage grinding process. At present, commonly used equipment in this process includes overflow ball mills, spiral classifiers, and hydrocyclones.

In actual gold beneficiation plants, the equipment for rock gold beneficiation needs to be determined according to its beneficiation process. Therefore, it is recommended to conduct beneficiation experiments and determine the suitable process through experimental analysis before determining the gold ore beneficiation equipment.

Gold Washing Plant | Gold Wash Process & Equipment

Gold Washing Plant | Gold Wash Process & Equipment How Gold Flotation Plant Work

How Gold Flotation Plant Work Sluice Box | Gold Sluice Box |Types & How To Choose

Sluice Box | Gold Sluice Box |Types & How To Choose Flotation Machine | Working | Applications | Types | Select

Flotation Machine | Working | Applications | Types | Select