Filter Press Breakdowns And How To Repair

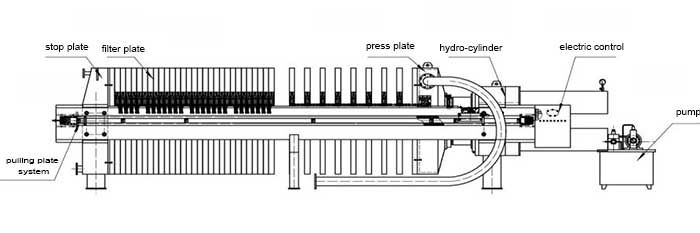

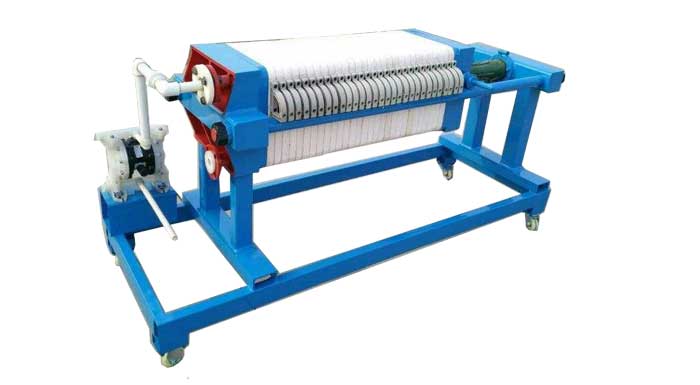

Nowadays, the application of filter press in sludge sewage treatment is more and more. In the process of using the filter press, various breakdowns may occur, which may lead to the failure of normal operation.

Following is a brief introduction of 21 common breakdowns of filter press and the solutions:

1. Insufficient Pressure

Solutions: The relief valve is damaged, repaired or replaced; the oil level is insufficient to supply hydraulic oil; the oil pump is damaged and replaced; the valve block and joint leak, tighten or replace O-ring; the oil cylinder seal ring is worn and replaced.

2. Poor Pressure Retention

Solutions: wear of piston seal ring, replacement of seal ring; leakage of oil path, maintenance of oil path; plugging or wear of hydraulic control one-way valve, cleaning or replacement; plugging or wear of solenoid ball valve, cleaning or replacement.

3. Fracture of Filter Plate

Solutions: when filtering, the feed pressure is too high to adjust the feed pressure; when the feed temperature is too high, change the high temperature plate or cool before filtering; when the feed speed is too fast, reduce the feed speed; when the feed hole of the filter board is blocked, the feed hole is cleaned up; when the filter cloth is broken, the outlet is blocked, the filter cloth is replaced and cleaned up; when the coal cake is not full, the cleaning inspection makes it possible to clean up the filter cloth. Coal cakes are full.

4. The Filter Plate is Raised Upward

Solutions: Installation foundation is uneven, foundation is repaired; slag removal at the bottom of filter plate is not clean and clean.

5. Unclear Filtrate

Solutions: filter cloth damaged, replacement of filter cloth; improper selection of filter cloth, re-test, replacement of filter cloth; filter cloth hole is too large, replacement of filter cloth; filter cloth suture line, re-stitching.

6. Noise in Hydraulic System

Solutions: Inhale air, open the vent valve to vent air; Fastener is loose, need tightened; Hydraulic oil viscosity is too high to reduce the viscosity of hydraulic oil.

7. Bending of Main Beam

Solutions: the oil cylinder end foundation rough degree of freedom is not enough, reinstallation; filter plate arrangement is not parallel, pull plate is not synchronous, rearrange the filter plate, adjust pull plate car synchronization; head plate is not correct, pressure filter support frame deformation, adjust and rectify.

8. Car without Pulling Plate

Solutions: Limit switch without signal, adjust the headboard position; car not in place, adjust the car position; replace relays.

9. Filter Cloth Damage

Solutions: filter cloth with more slime, timely flushing; first-stage cyclone damage, replacing the underflow nozzle.

10. Plate Merge Overtime

Solutions: The closing plate proximity switch is broken, and the proximity switch is replaced; the pulling plate motor, frequency converter, reducer and chain drive mechanism have failure, check and repair.

11. Plate Pressing Overtime

Solutions: pressure gauge damage, inspection and replacement; Hydraulic system failure, inspection and maintenance.

12. Feed Valve Overtime

Solutions: solenoid valve does not move, check and replace; trip switch is broken, check and repair and replace; insufficient air pressure, check and repair.

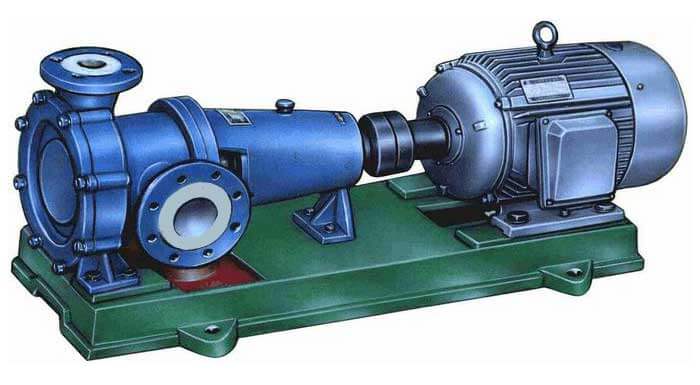

13. Feed Pump Start-up Can’t Feed Normally

Solutions: motor and pump coupling broken, inspection and maintenance; feed pipe blockage, cleaning.

14. Spraying Liquid

Solutions: insufficient pressure force, increase pressure force; filter plate edge with slime, cleaning slime; filter cloth folding, leveling filter cloth.

15. Stop Plate Not Move

Solutions: poor contact of proximity switch, check and replace proximity switch, stop plate failure, check brake motor.

16. Intake Valve Cannot Be Opened During Press

Solutions: Low intake pressure, check the air compressor; Intake pressure gauge is broken, change the pressure gauge.

17. Leakage of Filtrate Pipes

Solutions: The filter plate is damaged, check and replace the filter plate; the seal ring of the air inlet hole of the filter plate is removed, and the seal ring is repaired.

18. Filter Plate Release Overtime

Solutions: loosen the bad proximity switch, replace the proximity switch; hydraulic filter press failure, check and repair.

19. Head Plate Move Slower

Solutions: High and low pressure oil pumps are abnormal, oil filters are overhauled, air in the pump is discharged, and the performance of high and low pressure oil pumps is checked.

20. Pulling Plate Device Don’t return Well

Solutions: pulling-plate oil is insufficient, pressure relay does not work, adjust pressure relay spring and speed regulating valve, increase oil pressure.

21. Oil Pump Heating and Not Oiled

Solutions: incorrect steering of motor or oil pump, dirty oil, low oil level, problems with oil pump, etc., adjust the steering of oil pump or motor, clean oil pump and filter, refuel, check oil pump, etc.

The above list is the most common 21 kinds of filter press breakdowns(5 Common Belt Filter Breakdowns And How To Fix Them), encounter these faults, we can use the above methods to solve, or just contact the filter press manufacturers or professional filter press technician for help timely.

5 Common Belt Filter Breakdowns And How To Fix

5 Common Belt Filter Breakdowns And How To Fix Learn More About Filter Press (45 Filter Press Terminology)

Learn More About Filter Press (45 Filter Press Terminology) How To Select The Feed Pump of Filter Press

How To Select The Feed Pump of Filter Press Filter Press [Definition, Components, Types & Comparison]

Filter Press [Definition, Components, Types & Comparison]

V.Good Article you posted on your website.

We are facing issue in filter press plate damage in continue manner.

Request you to please guide what is the solution.