How To Select The Feed Pump of Filter Press

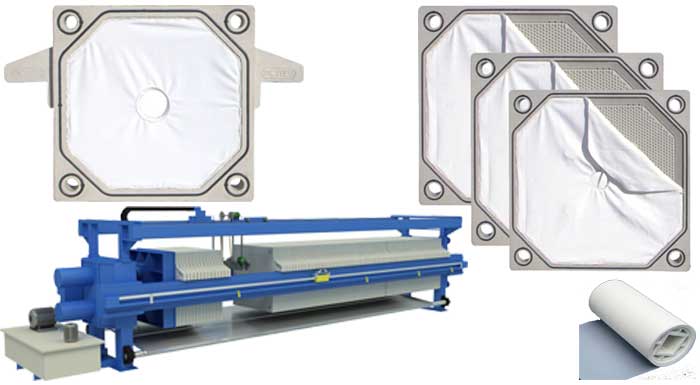

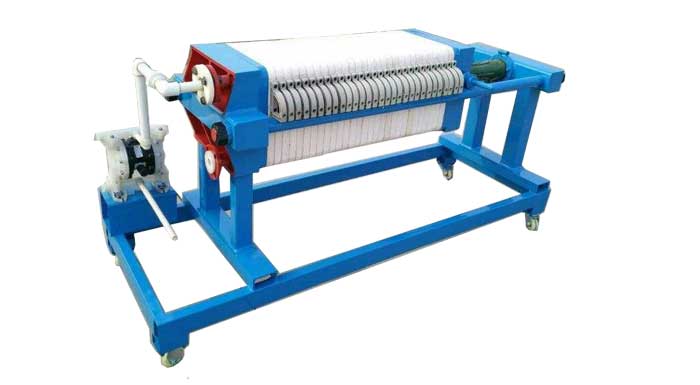

Filter press is a kind of filtration and separation equipment commonly used in mining, sludge, food and other industries. It was widely used in chemical industry, pharmacy, metallurgy, dyestuff, food, brewing, ceramics, environmental protection and other industries since the early 18th century.

Usually, filter press needs to be combined with supporting feeding pump. But, how many types of feed pumps are there? How to select the matching feed pump for filter press, and what are the precautions for selecting the filter press pump?

The auxiliary equipment of filter press can be roughly divided into 4 types:

- Filter Press Feed Pump

- Pipeline Connection of Filter Press

- Filtrate Collection Device

- Filter Cake Collection Device

Today, we will learn how to select the feed pump of filter press:

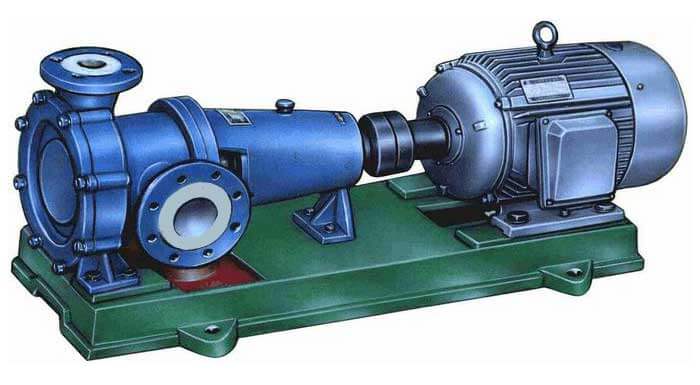

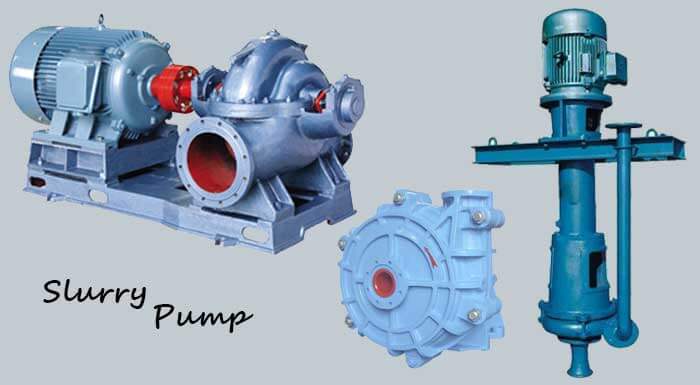

Filter press feed pump is also called “Filter Press Pump”. The most common feed pumps include: Centrifugal Pump, Screw Pump, Roots Pump, Diaphragm Pump, Plunger Pump etc. At present, centrifugal pumps are the most widely used in industry, including ordinary pumps, stainless steel pumps, mud pumps, slurry pumps, corrosion-resistant plastic pumps, etc.

Filter Press Pump Features

- Motor shall not be overloaded from large flow feeding at the initial stage of feeding to long-term high pressure at the later stage of pressing.

- The performance curve is steep. With the change of feeding resistance, the automatic conversion of large flow low pressure and small flow high pressure can be realized.

- Always keep high pressure without leakage.

How To Choose The Right Feed Pump

When selecting the matching pump for the filter press, first of all, it is necessary to know the filter area of the filter press used in the working condition, such as 50m², 100m², 200m², 250m², 300m² and so on.

When selecting feed pump according to the filter area of the filter press is the main basis for the filter press pump manufacturers at present. The pump manufacturers can match the size of pump, outlet, inlet diameter and required motor size according to the filter area provided by the customer.

Second, according to the slurries to be delivered. After the feed pump type is determined by the pump manufacturers, customers should provide the concentration and medium proportion of the slurry to be delivered, the manufacturers will determine the feed pump materials according to the parameters.

Third, feed pumps materials are cast iron, common alloy, high chromium alloy and stainless steel and other materials. At present, if the slurry is not particularly corrosive, the high chromium alloy filter press pump is the best one on the market. This kind of material has certain wear resistance and corrosion resistance. And the service life is much longer than cast iron pump and ordinary alloy pump, and the price is much cheaper than stainless steel material.

4 Tips You Need Pay Attention To

1. Select Specialized Feed Pump

In order to meet the working principle of the filter press, it is better to select specialized feed pump, If other types of pumps are selected, the basic parameters meet the requirements, but in actual operation, it is easy to break the pump shaft and other problems.

2. Determine Basis of Flow

The feed pump needs to be consistent with the working principle of filter press. It is required that when the feed pump starts to feed, the required pressure (lift) is low, while the large flow is required to fill the filter press chamber; when the pressure is maintained, the flow is basically not required, and the high pressure (lift) is required to discharge the water.

3. Determine Pump lift

The feed pump lift is not necessarily the higher the better. When the actual filter pressure is higher than the pressure required by the filter press, the filter cloths service life is often shorter.

4. Proper Transmission Mode

At present, feed pump adopts direct and indirect transmission. Considering the working characteristics of the feed pump and the service life of the overcurrent parts, most feed pumps adopt indirect transmission.

Filter Press Breakdowns And How To Repair

Filter Press Breakdowns And How To Repair 4 Popular Types of Slurry Pump & How To Select A Right One

4 Popular Types of Slurry Pump & How To Select A Right One Filter Cloth Types and How To Select Filter Press Cloth

Filter Cloth Types and How To Select Filter Press Cloth Learn More About Filter Press (45 Filter Press Terminology)

Learn More About Filter Press (45 Filter Press Terminology)