Flotation Machine | Working | Applications | Types | Select

A flotation machine is a commonly used equipment in mineral extraction and beneficiation processes, used to separate mineral impurities from the ore and improve its grade. The main function of flotation machine is to combine minerals with foam by virtue of affinity between minerals and foam, so as to achieve flotation purpose.

How Flotation Machine Work

The basic working principle of a flotation machine is to generate negative pressure through centrifugal action generated by the rotation of the impeller. On the one hand, sufficient air is sucked in to mix with the slurry, and on the other hand, the slurry is stirred to mix with the medicine.

After the slurry and air are fully mixed between the impeller blades, they are discharged from the periphery of the upper half of the impeller. The discharged mineral flows diagonally upwards and is stabilized and oriented by the stator installed above the impeller, and then dispersed throughout the entire groove. The mineralized bubbles rise to the upper surface of the tank body to form foam, which flows into the foam tank automatically, and the slurry returns to the impeller area for recycling.

Flotation Machine Applications

Flotation machines are mainly used for separating non-ferrous metals such as copper, zinc, lead, nickel, gold, etc. They can also be used for rough selection and selection of black metals and non-metals.

In the mining industry, flotation machines can distinguish useful minerals from waste rocks in ore, improving the grade and recovery rate of useful minerals. In the metallurgical industry, flotation machines can extract metals from various ores.

Types of Flotation Machine

Mechanical Stirring Flotation Machine

The inflation and stirring of the slurry in the mechanical stirring flotation machine are completed by the impeller and a customized mechanical stirring device. According to the type of mechanical stirring device, this type of flotation machine can be divided into different models, such as XJ type, XJQ type, GF type, SF type, rod type, etc.

The advantages of a mechanical stirring flotation machine are: it can self suction air and slurry, easy to achieve self flow when the ore returns, fewer auxiliary equipment, neat equipment configuration, and simple operation and maintenance; The disadvantages are small inflation, high power consumption, and significant wear and tear.

Inflatable Stirring Flotation Machine

The inflatable stirring flotation machine mainly relies on the rotation of the mechanical stirrer to stir the slurry, and uses a blower to achieve inflation. It belongs to the external gas supply flotation machine.

The characteristic of this type of flotation machine is that the inflation volume can be increased or decreased according to needs and is easy to adjust to maintain a constant state; The impeller does not provide suction, resulting in low rotational speed, low power consumption, and minimal wear; The disadvantage is that an additional set of compressed air system is required, and intermediate products need to be pumped back with a sand pump.

Inflatable Flotation Machine

The inflatable flotation machine does not have a mechanical agitator or transmission components, and is provided with air for inflation by a specially designed pressure fan.

The advantage of this type of flotation machine is its simple structure and easy manufacturing. The disadvantage is that the lack of an agitator affects the flotation effect to a certain extent, and the aerator is prone to calcium deposition, which is not conducive to air dispersion.

How To Select Flotation Machine

Selection of a flotation machine should ensure that it can meet the production requirements and have good flotation performance. The following are some key factors in selecting a flotation machine:

- Ore Properties: large particle size and density of the feed material, the flotation machine should be prioritized for its suspension capacity, i.e., the slurry circulation performance in the tank. Flotation machines with shallow tanks and strong agitation are usually more suitable for this type of ore.

- Slurry Flow: large flotation machine has an advantage in processing a large amount of slurry. According to the production scale and product requirements, calculate the necessary single tank volume, so as to determine the flotation machine specifications.

- Wear Parts: The wear parts of the flotation machine should have a long enough life to minimize maintenance and replacement costs. In addition, the changes in mixing capacity and aeration after wear should be as small as possible to keep the performance of the flotation machine stable.

- Flotation Machine Type: According to the nature of ore, sorting operation and process requirements, choose the most suitable type of flotation machine. Mechanical stirring flotation machine has less auxiliary equipment, and the equipment is simple and convenient to operate, maintenance difficulty is relatively small, the equipment parts configuration requirements are relatively low, it is more suitable for the use of small-scale mineral processing plant.

- Technical Parameters: when choosing a flotation machine, you also need to consider its technical parameters, such as model, size, capacity, motor power, etc.. According to the site conditions and process requirements, choose the right size. The flotation machine with smaller inflatable capacity is generally suitable for selective operation with thicker foam layer.

Flotation machine is an important mineral extraction and beneficiation equipment. By mastering its working principle and classification, selecting a suitable flotation machine can better play its role in the mining field, improve ore grade, and reduce production costs.

How Gold Flotation Plant Work

How Gold Flotation Plant Work VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications Types of Flotation Reagents and Their Function

Types of Flotation Reagents and Their Function 4 Popular Types of Slurry Pump & How To Select A Right One

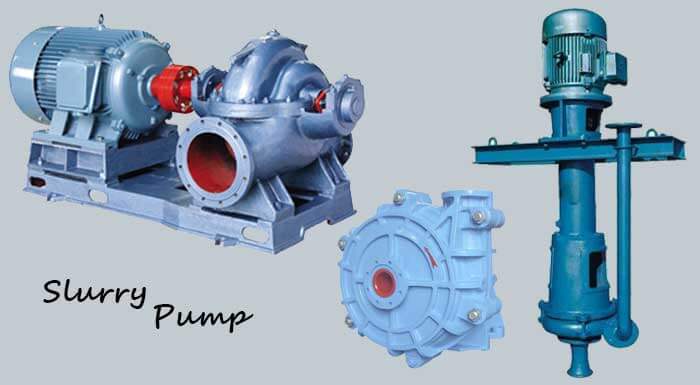

4 Popular Types of Slurry Pump & How To Select A Right One