Different Crushing Types Among 7 Crushers

Crusher is an indispensable part of stone crushing, sand making and grinding, but there are many kinds of crushers in the current mining equipment market. How to select a suitable and satisfactory crusher? First of all, you need to know the different crushing type features of these different crushers.

What Is Crushing Types?

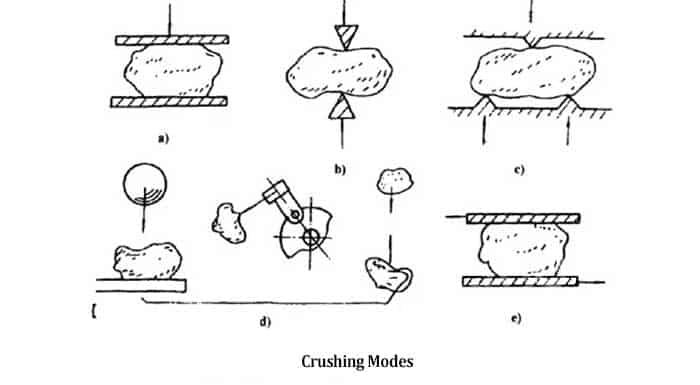

The crushing types include: extrusion, splitting, breaking, shearing, impact or impact, etc., generally a mixture of multiple modes of action, there is no single mode of action.

Extruding and Crushing: the work of the crushing machine exerts pressure on the material sandwiched between it, and breaks when the compressive stress of the material reaches its compressive strength limit.

Split Shear Crushing: the edge of the crushing face wedges into the material and causes the internal tensile stress. When its value exceeds the tensile strength limit of the material, the material splits and produces powder locally at the point of contact between the sharp edge and the material.

Bending and Breaking: materials sandwiched between working faces, such as simply supported beams or multi-supported beams acted by concentrated forces, are mainly subjected to bending stress, but are subjected to splitting at the contact of the working face.

Extrusion Shearing: a combination of extruding crushing and shearing crushing.

Impact Crushing: impact crushing includes the impact of the broken body of the high-speed movement on the broken material, the impact of the high-speed moving material on the fixed wall and the mutual impact of the moving material.

Different Crushing Types of 7 Common Crushers

1. Jaw crusher

The jaw crusher works intermittently. The stone is crushed by the swing of fixed jaw and moving jaw. Some time ago, a friend left a message to inquire about Jane pendulum jawbone. In fact, it is rarely used now. It is mainly compound pendulum jawbone.

Application: it is suitable for a wide range of materials, both soft and hard, especially for coarse and medium crushing of hard stones.

Advantages: simple structure, reliable operation, light weight, low price, small overall size, low configuration height, large size of feed inlet, easy adjustment of discharge opening, simple maintenance and economic operation cost.

Disadvantages: the lining plate is easy to wear and the content of needle and flake in the product is high, so it is generally necessary to configure feeding equipment.

2. Cone Crusher

The work of the cone crusher is continuous, and the stone is crushed by the eccentric movement of the moving cone. At the same time, because of the tangential movement of the moving cone and the fixed cone, the stone is also subjected to shear grinding, so its working mechanism is the combination of extrusion, shearing and grinding.

Application: mainly used for crushing or fine crushing of all kinds of stone. At the same time, according to its different structure (suspended shaft type and supporting shaft type), it can also be used for rough crushing of stone (suspended shaft type is less used).

Advantages: large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable work, low failure rate, not easy to over-crush.

Disadvantages: complex structure and maintenance, high body and high price.

3. Rotary Crusher

The rotary crusher is continuous crushing, which adopts the principle of intermaterial lamination crushing, and the crushing process is carried out continuously along the annular crushing cavity.

Application: it is mainly used for crushing materials of various hardness in the first stage, but it is not suitable for crushing viscous ore.

Advantages: large crushing ratio, high production capacity, can be packed with ore feeding, can be directly fed without equipped with feeder.

Disadvantages: complex structure, high fuselage, large volume, need high factory buildings, large investment in infrastructure construction, heavy machinery, inconvenient handling, high price.

4. Roller Crusher

The work of the roller crusher is continuous, and the stone is located between two parallel cylindrical rollers moving opposite to each other. The stone is bitten into the roller by the friction between the stone and the roller, the stone of the smooth roller is extruded, and the stone of the tooth roller is broken by splitting and extrusion.

Application: mainly used for medium and fine crushing of medium hardness stone such as coal and limestone (compressive strength below 100MPa). Roller crusher is not used in road crushing.

Advantages: simple, compact structure, low investment, convenient adjustment, can be used for crushing viscous materials.

Disadvantages: low production efficiency, unable to break hard materials.

5.Impact Crusher

The work of the impact crusher is continuous, and the high-speed moving materials are broken because of hitting the iron wall, striking each other and rubbing against each other, so there are two kinds of words: “stone impact stone” and “stone impact iron”.

Application: “stone impact stone” is suitable for materials with high abrasion above medium hardness, and the finished product has better grain shape and slightly more powder content; “stone impact iron” is suitable for materials with low abrasion below medium hardness, with high crushing efficiency and high wear cost of peripheral guard plate. the finished product grain shape is slightly worse.

Advantages: low energy consumption, high output, large crushing ratio, small equipment size, simple operation, convenient installation and maintenance, shaping function, cubic product, high packing density, little wear and tear on the machine reaction board during operation.

Disadvantages: complex maintenance and high cost, the general maximum feed size is not more than 60mm, suitable for fine crushing and sand making.

6. Hammer Crusher

The work of the hammer crusher is also continuous, using the hammerhead on the high-speed rotating rotor to break the stone.

Application: it is suitable for crushing and fine crushing of medium, low hardness and non-abrasive stone (compressive strength less than 100MPa). It can also be used for sand making when there are grate bars, but it has been rarely used.

Advantages: large crushing ratio, high output, more fine materials.

Disadvantages: the hammerhead wears quickly, needs to be replaced frequently, the work is dusty, and the viscous material with moisture content of more than 12% can not pass effectively.

7. Counterattack Crusher

Counterattack crusher is a kind of machine which uses impact energy to break the material. Adjusting the gap between the counterattack frame and the rotor can achieve the purpose of changing the discharge particle size and shape of the material.

Application: mainly used for medium and fine crushing of stone below medium hardness, and the stone has a better shape after crushing.

Advantages: small size, simple structure, uniform product size, selective gravel, high output.

Disadvantages: plate hammers and reaction plates are particularly easy to wear, especially broken hard rock, wear is more serious, need to be replaced frequently; should not break plastic and viscous materials.

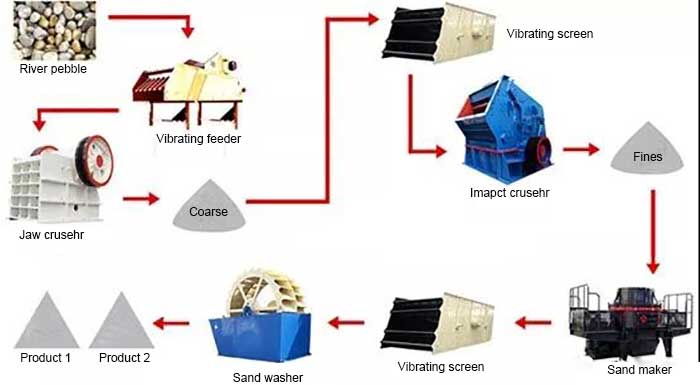

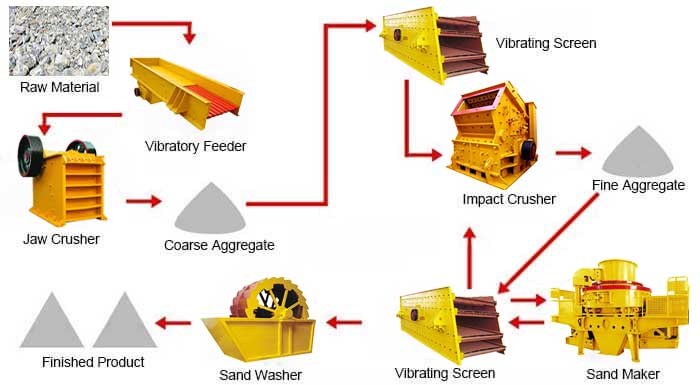

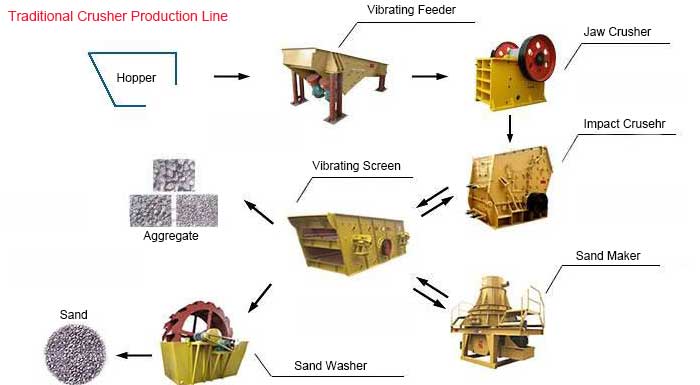

5 Types Crusher Equipments For Sand And Aggregate Production Line

5 Types Crusher Equipments For Sand And Aggregate Production Line Jaw Crusher VS Impact Crusher

Jaw Crusher VS Impact Crusher Mobile Crushing Plant For Recycled Aggregate

Mobile Crushing Plant For Recycled Aggregate Top 10 Crusher Machine Working Principle

Top 10 Crusher Machine Working Principle

Our main series: Jaw Crusher, Compound Sand Making Machine, Hammer Crusher, Vertical Impact Crusher, Simon Cone Crusher, Single Cylinder Hydraulic Cone Crusher, European Jaw Crusher, Reversible Crusher, Vertical Shaft Impact Crusher, Sand Washer, Vibrating Screening Machine, supporting facilities and other related products.

Cooperate with us you will receive, a one-stop solution, experience is superior, manufacturers direct supply, price is more according to the advantage, fast delivery cycle, and after-sales service is more secure.

Please reply if you are interested, looking forward to cooperating with you!

Greetings.