Jig Machine | 4 Types of Jigger Machine|How To Choose

What is Jig Machine (Jigger)?

A jigger refers to the equipment that implements the jigging process. The material is mainly sorted according to density differences in the variable speed medium flow of vertical lifting.

The differences in particle size and shape of materials have a certain impact on the results of jigging beneficiation. The medium used in jigging can be water or air. When water is used as the sorting medium, it is called hydraulic jigging; When air is used as the sorting medium, it is called wind jigging.

Jig machine is suitable for processing medium/coarse ore, with a particle size limit of 50mm, a lower limit of 0.2-0.074mm, and preferably 18-2mm. Jigs are commonly used for coal selection, tungsten, tin, and gold ore selection, as well as for iron, manganese ore, and some non-metallic ores.

Jigger Machine Working Principle

Jigging beneficiation is one of the gravity separation methods, which loosens the ore particles under the action of alternating vertical medium flow, and then stratifies them according to the specific gravity difference. Light minerals are in the upper layer and heavy minerals are in the lower layer, thus achieving the purpose of sorting.

When working, the material to be processed enters the sieve plate of the jig machine and is layered according to specific gravity in the vertically moving medium flow. Particles with lower specific gravity are located at higher levels, while particles with higher specific gravity are located at lower levels. Then, through the action of machinery and water flow, different layers of materials are discharged separately.

In the jigging process, the higher the specific gravity of the medium, the greater the difference in specific gravity between ore particles, and the higher the sorting efficiency.

How Many Different Types of Jig Machines?

There are many types of jigs, and according to the different mechanisms and ways of generating pulsating water flow, jigs can be roughly divided into piston jigs, diaphragm jigs, air pulsating jigs, hydraulic pulsating jigs, and moving screen jigs. Diaphragm jigs are commonly used in metal mine beneficiation plants, while air pulsating jigs are commonly used in the coal preparation industry.

1. Piston Jig Machine

A piston jig machine a type of machine that generates a vertically rising pulsating water flow through the reciprocating motion of the piston. It is the early form of jiggers, which have been basically replaced by diaphragm jiggers and air pulsation jigs.

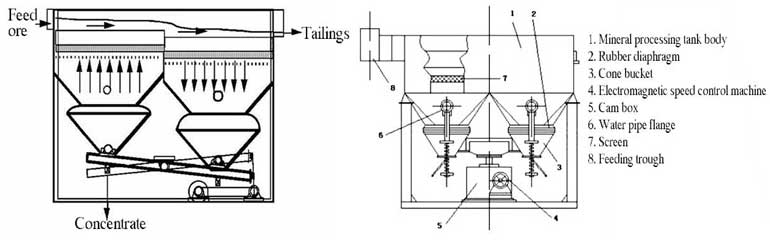

2. Diaphragm Jigger Machine

Diaphragm jigger machine replace pistons with diaphragms. Its transmission device is mostly an eccentric connecting rod mechanism, and there are also cam lever or hydraulic transmission devices used. The shape of the machine is mostly rectangular or trapezoidal, and in recent years, circular shapes have emerged.

According to the different installation positions of the diaphragm, it can be divided into upper moving, lower moving, and side moving diaphragm jigs.

3. Air Pulsating Jig Machine

The vertical alternating movement of water flow in an air pulsating jig machine (also known as a piston less jigger) is carried out using compressed air. According to the different positions of the air chamber of the jigger machine, it is divided into the side air chamber (side drum type) and the under screen air chamber of the jigger. This type of jig is mainly used for coal preparation.

4. Moving Jigging Machines

There are 2 types of moving jigging machines: mechanical moving jigger and manual moving jigger, now manual moving jigger is less commonly used.

Mechanical moving jigger is a device that directly relies on the moving jigger mechanism to drive the screen plate to move up and down in a water medium through hydraulic or mechanical means, causing the material on the screen plate to periodically loosen. This type of jigging machine is mainly used for the discharge of lump coal in large coal preparation plants, especially in cold and water scarce areas.

Factors Affecting the Beneficiation of Jiggers

- Coal Material Physical Properties: The physical properties of coal have a decisive impact on the effectiveness of jigging separation. The physical properties of coal, such as selectivity, density, particle size, and moisture content, can all affect the sorting effect. Among them, the washability and density of coal are the most influential factors.

- Jigger Working System: The working system of a jigger also has a significant impact on the sorting effect. The work system mainly includes parameters such as jigging frequency, amplitude, bed thickness, air valve characteristics, feeding amount, air volume, and water volume.

- Operation: Operational factors include the skill level, sense of responsibility, and work attitude of the operators.

- Environment: Environmental factors include temperature, humidity, air pressure, dust, etc. These factors may affect the normal operation and operation of the jigger, thereby affecting the sorting effect.

- Raw Coal Properties: The properties of raw coal can also affect the sorting effect of the jigger. The properties of raw coal include moisture, ash content, sulfur content, hardness, etc. The properties of raw coal determine its processability and processing difficulty, which in turn affects the sorting effect of the jigger.

How To Choose A Suitable Jig Machine?

Choosing a suitable jig requires comparing multiple factors, including processing capacity, size and structure, stability, energy consumption and maintenance, brand and service, and special needs. It is recommended to conduct sufficient market research and comparison before selecting to ensure that the selected jigs can meet actual needs and have a high cost performance ratio.

- Processing Ability: Choose a jig with suitable processing ability according to your needs. If the amount of material to be processed is large, it is necessary to choose a jig with strong processing capacity.

- Size & Structure: Select the appropriate size and structure of the jig based on the site space and usage environment. Ensure that the jig can be installed and used safely and conveniently.

- Stability: The stability of the jig is crucial for continuous production and product quality. Choose a jig with a sturdy structure and stable operation to ensure long-term stable production.

- Energy Consumption & Maintenance: Consider the energy consumption and maintenance costs of the jig. Choosing jigs with high energy efficiency and low maintenance costs can help reduce production costs.

- Brand & Service: Choosing a well-known brand and a jig with good after-sales service can ensure product quality and reliability of later maintenance.

- Special Requirements: If there is a demand for the special performance of the jig, such as high precision and specific functions, special attention should be paid to the relevant parameters and performance indicators when selecting.

Hot 20 Types Mineral Separation Machine [Principle GIF]

Hot 20 Types Mineral Separation Machine [Principle GIF] Feeder Machine Types | How To Choose A Feeder Equipment

Feeder Machine Types | How To Choose A Feeder Equipment Flotation Machine | Working | Applications | Types | Select

Flotation Machine | Working | Applications | Types | Select Coal Preparation Plant | Coal Preparation Process | Coal Washing

Coal Preparation Plant | Coal Preparation Process | Coal Washing

I need to process gold tailings with particle size between 100mesh to 150mesh. Will it works effectively?