4 Popular Types of Slurry Pump & How To Select A Right One

Slurry pump is a kind of centrifugal pump. In concept, slurry pump refers to a kind of machinery which increases the energy of solid-liquid mixed medium by virtue of the centrifugal force (the rotation of the impeller of the pump), and converts the electric energy into the kinetic energy and potential energy of the medium.

In the market, there are many types and models of slurry pumps. Different types of slurry pumps are widely used for slurry transportation in metallurgical concentrators, hydraulic ash removal in thermal power plants, coal slurry and heavy medium transportation in coal washing plants, slurry lifting in sand washing plants, river dredging, etc.

Popular Types of Slurry Pumps

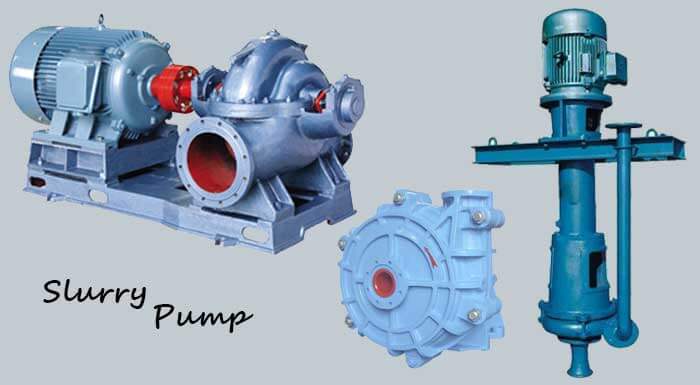

There are 4 main types of slurry pumps:

There are 4 main types of slurry pumps:

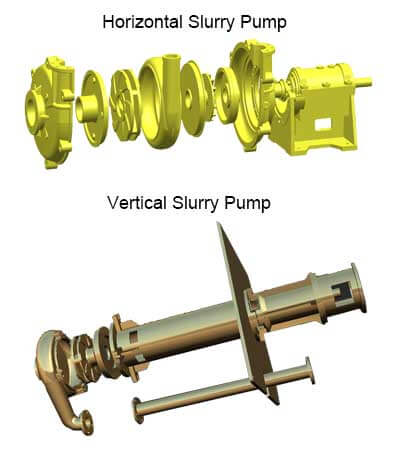

- Horizontal Slurry Pump

- Vertical Slurry Pump

- Submerged Slurry Pump

- Submersible Slurry Pump

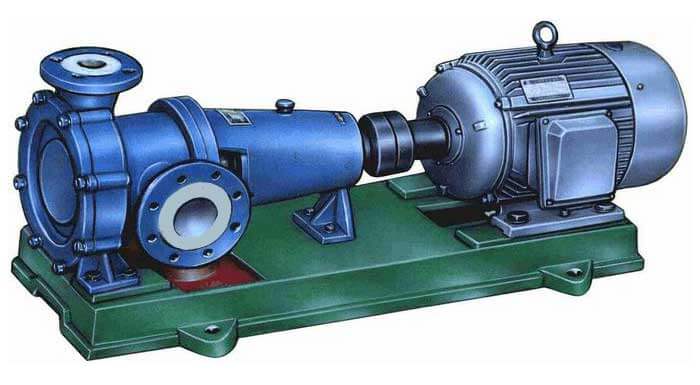

Horizontal Slurry Pump

When the position of the pump shaft is parallel to the horizontal plane, it is called Horizontal Slurry Pump. The horizontal slurry pump is a single-stage single-suction axial suction cantilever horizontal centrifugal pump with high-strength and wear-resistant materials for the over-flow parts. according to the different suction media, the filter components of various materials can be exchanged.

Horizontal slurry pump is suitable for conveying strong abrasion, high concentration, corrosive large or fine particle slurry, this series of slurry pump can be widely used in metallurgy, mining, electric power, coal mine and other industries to transport abrasive slurry containing a large number of solid materials.

Vertical Slurry Pump

When the position of the pump shaft is perpendicular to the horizontal plane, it is called a Vertical Slurry Pump. Generally, the vertical slurry pump is used in the slurry pool to pump the slurry, and the pump head should be placed below the liquid level, so it is also called the Submerged Slurry Pump, but not all the whole pumps are submerged into the water. if the motor and other non-pump head components are also put into the slurry, the pump is called Submersible Slurry Pump.

Vertical slurry pump is mainly suitable for conveying corrosive, coarse particles and high concentration slurry.

Submerged Slurry Pump

Submerged Slurry Pump

The Submerged Slurry Pump is a vertical single-stage single-suction cantilever centrifugal pump, the impeller is a semi-open impeller, and a mixing blade is arranged at the suction edge extension of the impeller.

The main features of the submerged slurry pump are that the length of the pump shaft in the submerged part is between 800-2000mm, there is no bearing between the impeller and the pump shell, the driving unit is installed on the motor support and support seat by the vertical motor, and the coupling is used to connect with the pump.

Submerged slurry pump is mainly used in municipal engineering, paper mills, cement plants, printing and dyeing plants and other industries to pump slurry, quicksand, sludge and other fluids.

Submersible Slurry Pump

Submersible Slurry Pump

Submersible Slurry Pump is the coaxial integration of the pump and the motor, and the motor submerges into the slurry. There is no need to build complex fixtures and protective measures on the ground. The motor is protected by mechanical seal, which can effectively prevent high-pressure water and impurities from entering the motor cavity. The stirring impeller touches the deposition surface directly, and the slurry concentration is controlled by the diving depth, and the slurry automatically pours into the pump to save energy.

Submersible slurry pump is suitable for conveying slurry containing abrasive particles such as sand, cinder, tailings, etc., mainly used in metallurgy, electric power, river dredging, sand extraction, municipal mud process and other industries.

Basic Structure of A Slurry Pump

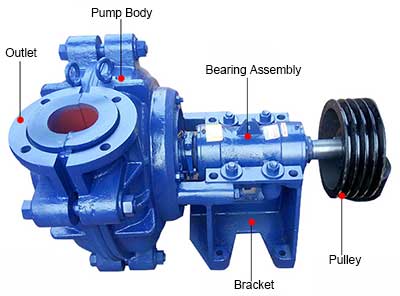

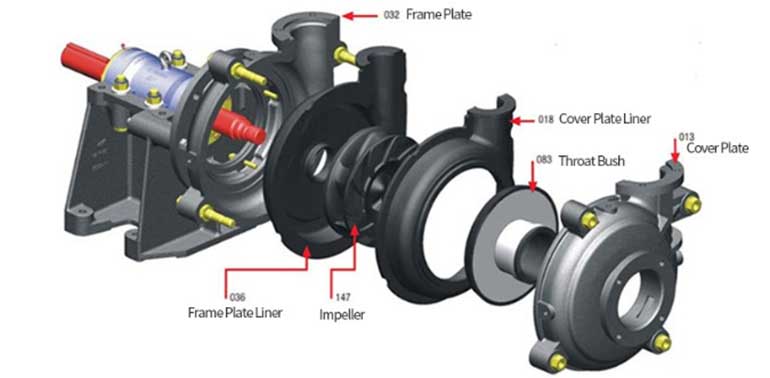

1. Pump Head

The pump body adopts double-layer pump housing (double-layer metal structure inside and outside); the double pump housing structure is vertical split type, and the water outlet can be installed and used in 8 different positions according to 45 degree interval;

In order to effectively prevent the leakage of shaft seal, the combination of power seal, packing seal or mechanical seal is adopted;

Labyrinth clearance seal is set between impeller and back guard plate, which greatly reduces the leakage of slurry to stuffing box and effectively ensures the reliability of seal.

2. Bracket Structure

The bracket structure of slurry pump has horizontal split type and barrel type. Correct selection of bearing form, model, cooling and lubricating mode, etc., so that the radial force and axial force can be reasonably distributed to extend the service life of the bearing.

3. Shaft Seal

The shaft seal device plays a sealing role between the pump body and the pump shaft, which can prevent air from entering the pump and a large amount of water from leaking out of the pump. Shaft seal forms include: auxiliary impeller power seal + packing seal, packing seal and mechanical seal

4. Bearing Assembly

The bearing assembly of slurry pump adopts cylinder structure, which is convenient to adjust the clearance between impeller and front guard board, and can be removed as a whole during maintenance. The bearing is lubricated with grease.

5. Driving Device

Elastic coupling drive, narrow V-belt drive, gear drive and variable frequency drive.

How A Slurry Pump Work

The Working Principle of a slurry pump is that: Under the action of centrifugal force, the slurry/mud is thrown from the center of the impeller to the outer edge and obtains energy to leave the outer edge of the impeller and enter the volute pump shell at high speed. In the volute pump shell, the slurry slows down due to the gradual expansion of the flow channel, and converts part of the kinetic energy into static pressure energy, and finally enters the discharge pipe with higher pressure and sends it to the place where it is needed.

When the slurry flows from the center to the outer edge of the impeller, a certain vacuum is formed in the center of the impeller. because the pressure above the liquid level of the storage tank is greater than that at the inlet of the pump, the slurry is continuously pressed into the impeller, thus making the slurry pumps feed continuously.

How To Select The Right Slurry Pump

The reasonable selection of slurry pump is the key factors to improve the service life of the pump and save slurry pump costs. The reasonable selection of slurry pump includes reasonable selection of slurry pump type, performance parameters, material of overcurrent components, sealing type and transmission mode, and so on. The following 7 steps teach you to choose the best slurry pump for your applications:

1. Firstly, the type of slurry pump is determined according to the user’s on-site working conditions. Horizontal slurry pump is suitable for import with certain pressure, while vertical slurry pump is suitable for mud pool.

2. According to the acidity and alkalinity of the slurry, we can judge what material is used for the overflowing parts, such as: acidity can be made of A49, Cr30 or natural rubber. And for large particles and strong impact pulp, it is better to select metal wear-resistant material flow passage parts, while for small particles and non sharp edges and corners pulp, it is better to select rubber material flow passage parts.

3. Motor selection for slurry pump. The motor power of the slurry pump should be 1.2 times of the shaft power of the slurry pump, because the power loss may be caused by the friction between the slurry and the pump body and the overload operation during the operation of the slurry pump.

4. Determine the sealing mode. There are 3 kinds of sealing methods: packing seal, pressure relief cover auxiliary impeller seal and mechanical seal.

5. Confirm the driving type. The driving types of slurry pump are V-shaped triangle belt drive, elastic coupling drive, gear reducer drive, hydraulic coupler drive, frequency conversion drive, SCR speed regulation. Among them, the price of elastic couplings and V-shaped triangular belts are lower and it’s convenient to disassemble and assemble, so they should be given priority.

6. According to the flow and head parameters provided by the user, the appropriate slurry pump is selected according to the water performance curve of the slurry pump after the surplus is increased, and the motor power is calculated.

7. Confirm the footprints of the working site with the users, and design the installation drawings and provide the installation precautions of the slurry pump.

Basic Calculations of Slurry Pumps You Need Know

Flow (Q): the quantity of liquid discharged by the pump in unit time, (unit: m³/h, m³/s. l/s).

Head (H): the energy obtained by unit weight liquid passing through the pump, (unit: m).

Rotation Speed (n): revolutions per minute of pump shaft, (unit: r/min).

Shaft Power (P): power required for motor driven pump, (unit: KW).

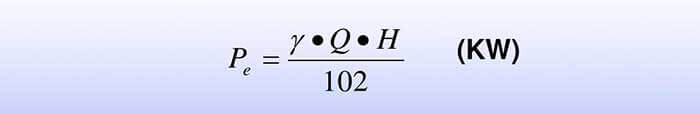

Pump Effective Power (Pe): the product of the flow and head of the pumped liquid (slurry).

Y – liquid density, (kg/m³)

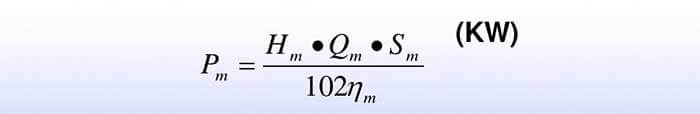

Slurry Shaft Power (Pm): the pump shaft power when pumping slurry is called slurry shaft power, (unit: KW).

Hm – slurry head, (m); Qm – slurry flow, (l/s)

Efficiency (n): the ratio of effective power to shaft power, it’s a physical quantity to measure the power capacity of the pump.

How To Select The Feed Pump of Filter Press

How To Select The Feed Pump of Filter Press Flotation Machine | Working | Applications | Types | Select

Flotation Machine | Working | Applications | Types | Select Filter Press Breakdowns And How To Repair

Filter Press Breakdowns And How To Repair Spiral Washers VS Spiral Classifiers

Spiral Washers VS Spiral Classifiers

Good Day,

Please send us your best quotation for pricing and availability for 40 pieces of Self Priming Centrifugal:

Pump:Type/Model:Number:APE9B85‐73

Parts/Serial/Model Number:APE9B85‐73

Quantity:40 pieces

Please:send your quotation as soon as possible

We are looking forward to recieve your best quotation

ok sir

Dear Sir,,

We are a Unit of DCM Shriram Industries Ltd, engaged in manufacturing Rayon tire yarn, cord and fabrics and export these products to world’s leading tyre manufacturers in European countries and Japan.

We have a requirement of the following item(s). If you are in position to item(s) scheduled below, please send us your best competitive offer with detailed Techno-Commercial Details;

A. Scope of Supply

Belt Press for ETP Sludge Inlet Flow of Sludge : 20 m3/hr, Input Sludge Solid content: 2 – 4%, Sludge Output: 5 MT on dry basis.

Quotation due date: Immediate

Submission of Requirements

1. The supplier shall quote SSI Registration (If applicable) along with GSTIN, PAN Nos.

2. The supplier shall submit all the imperative parameters such as Discount, duties and Taxes, confirmed delivery period & payment terms.

3. The prices shall be quoted with Incoterms DAP, Kota ( Incoterms) specifying the Make or any further information considered necessary.

4. The prices shall be including erection and commissioning at our Site, Kota Rajasthan if any.

5. Quotation shall be compared and evaluated on the basis of completeness of submission, compliance with Technical Specification, Price, Quality and serving customers lists.

Best regards

Ram Kshetri

thank you for your inquiry, we will contact you

we have enquiry of 1-00 HP vertical slurry pump. can you send us details with price. Urgent.

We can supply WARMAN type slurry pumps for you with high quality,competitive price and fast lead time,contact us for more information.

we have enquiry of 1-00 HP vertical slurry pump. can you send us details with price. Urgent.

we have cement factory

need slurry pump horizontal

q 120 m3 / hr

head 50 m

in diameter 6 in out diameter 4 in

slurry density 1500 kg / m3

Ok sir, i will contact you and send you the slurry pump details

We can offer the slurry pump,please contact me,let’s talk details.