VSI Sand Making Machine | Working Principle & Applications

What Is VSI Sand Making Machine

VSI sand making machine is the latest sand maker, which can save 50% energy compared with traditional sand making machine. VSI sand making machine is mainly used for building sand making. It can process all kinds of rocks, sandtone and pebbles into building sand of all sizes. The manufactured sand has uniform grain size and high compressive strength, which is far more in line with the construction requirements than the natural sand or the sand produced by the ordinary hammer sander.

VSI sand making machine is a popular equipment in the field of artificial sand making and stone shaping. It is specially designed to provide high quality sand and aggregates for highways, high-speed railway, building, municipal, hydropower dam construction and concrete mixing stations.

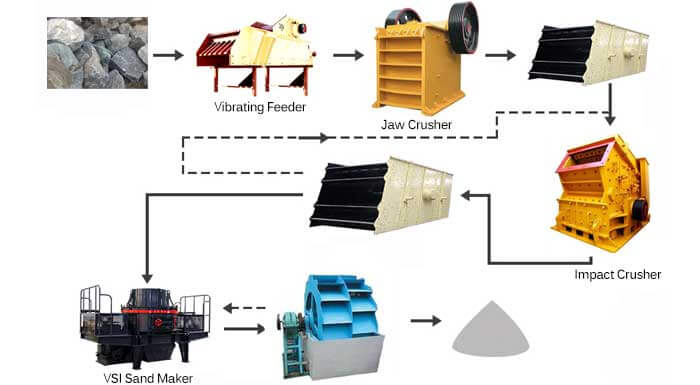

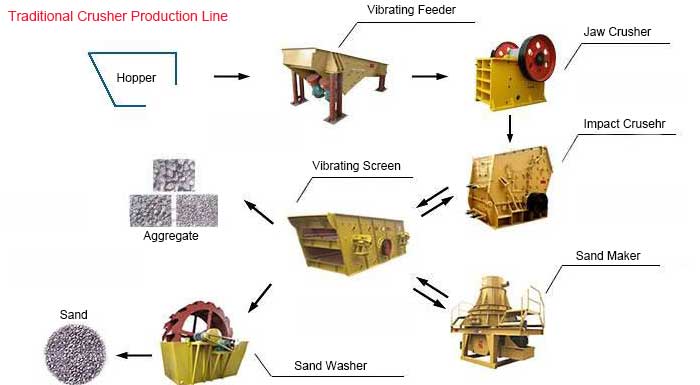

VSI sand making machine is usually used in combination with sand washing machine, crusher, vibrating screen, vibrating feeder, etc.

How VSI Sand Making Machine Work

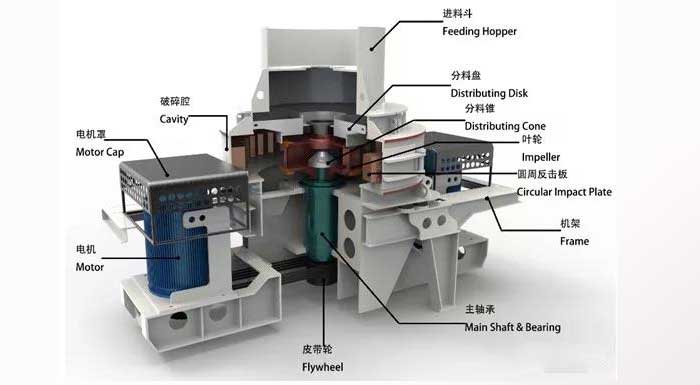

VSI sand making machine uses high-speed rotating materials to break each other and friction between materials (stone strike stone). When working, the material enters the crushing chamber of VSI sand making machine vertically from the upper part. Under the centrifugal force of high-speed rotating impeller, the material interacts and collides with each other.

The maximum feed particle size is generally ≤ 80mm, materials larger than the prescribed particle size are strictly forbidden to enter the crusher, the maximum water content of the feed material is ≤ 20%. Generally, the ore from the sand washing machine can directly enter the VSI sand making machine.

The discharge particle size of VSI sand making machine is related to the physical properties of the ore and the feed particle size. If the ore is fragile, the smaller the feed size is, the higher the qualified rate of product particle size is. The particle size of the product can also be adjusted by changing the impeller speed. In order to ensure that the qualified rate of particle size reaches 100%, grading equipment is used for closed-circuit crushing.

Hot Applications

- 1. Artificial Sand Making: sand production of river pebbles, mountain stones (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, stone chips and other materials.

- 2. Aggregate Making: production of building aggregate, road fabric, bedding material, asphalt concrete and cement concrete aggregate.

- 3. Engineering Field: machine made sand production and stone shaping for water conservancy and hydropower, road and bridge, municipal engineering.

- 4. Mining Process: fine crushing in the front section of grinding process, crushing materials for building, metallurgy, chemical industry, mining, refractories, cement, abrasives and other industries.

- 5. Environmental protection projects such as high abrasion and secondary disintegration and crushing, desulphurization in thermal power and metallurgical industries, crushing of steel slag and construction waste, etc.

- 6. Glass, quartz sand and other high purity materials processing.

How To Select Sand Making Machine?

How To Select Sand Making Machine? Top 10 Crusher Machine Working Principle

Top 10 Crusher Machine Working Principle Jaw Crusher Working Principle | Applications| Benefits

Jaw Crusher Working Principle | Applications| Benefits Flotation Machine | Working | Applications | Types | Select

Flotation Machine | Working | Applications | Types | Select

I need sand making machine to reduce the particle size from 2 mm become 0.6 mm