What is Trommel Screen and How Does It Work

What is Trommel Screen

Trommel screen, or rotary screen, is a kind of mechanical screening machine which is widely used in the separation operation. It controls the material separation by the particle size, and the separation precision is high. The cylinder of the trommel screen is generally divided into several sections, depending on the specific situation. The mesh holes are arranged from small to large, and the mesh hole diameter on each section is the same.

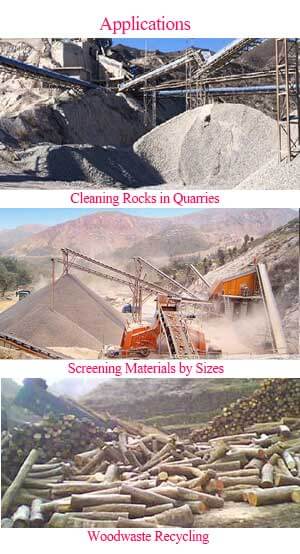

Trommel screens are widely used for wood chips, soil, compost, solid waste, domestic waste, ores, rock and aggregates accurate sizing and separation.

Trommel screen is mainly composed of motor, reducer, roller device, frame, sealing cover, inlet and outlet.

How Trommel Screen Work

The cylindrical drum is mounted obliquely on the frame. The motor is coupled to roller device via the reducer and drive the drum rotates around its axis.

When the material enters the drum screen, due to the inclination and rotation of the roller device, the material on the screen surface will turn over and roll, so that the qualified material will be discharged through the outlet at the bottom of the drum, and the unqualified material will be discharged through the outlet at the end of drum.

Due to the overturning and rolling of the material in the drum, the material stuck in the screen hole can be ejected to prevent the screen hole from blocking.

Advantages of Trommel Screen

1. Rolling conveying principle, small friction coefficient, and the screen hole is not easy to be blocked.

2. The roller support adopts the overall through shaft structure, which is stable in operation, free from vibration and low in noise.

3. The internal trommel screen accessories adopt the split design, with simple structure and quick and convenient replacement and maintenance.

4. The roller device adopts an effective fully sealed structure, which is dust free and pollution free.

5. The operation is safe and reliable. The reducer is adopted with high transmission efficiency, small belt power, low energy consumption and obvious energy saving effect.

6. Trommel screen manufacturers choose different screen materials according to different needs of customers to prolong the service life of roller screen and reduce maintenance costs.

7. Special screen is adopted, with high screening efficiency and long service life.

8. The main frame of heavy steel structure is designed with components for minimizing material accumulation.

9. Trunnion components mounted to heavy duty roller bearings to prolong service life.

10. Small installation inclination angle and good screening effect.

11. Portable trommel screen is flexible and suitable for small and medium-sized concentrators that need to move.

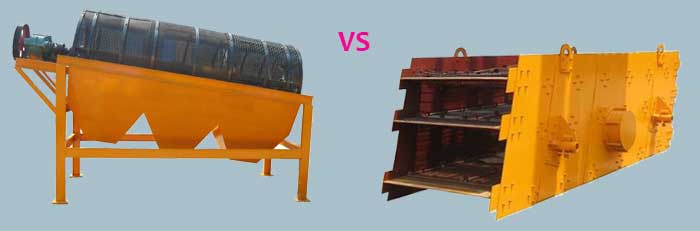

Trommel Screen VS Vibrating Screen

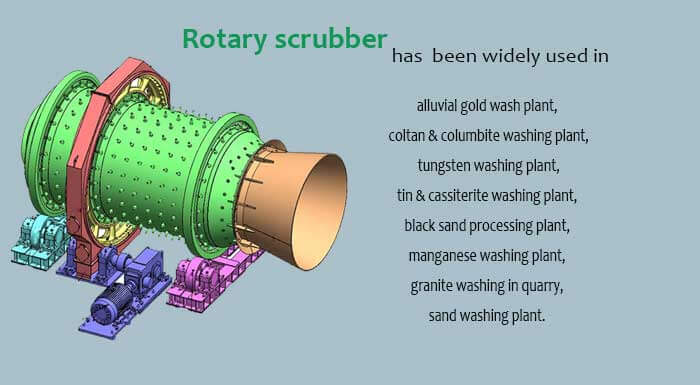

What is Rotary Scrubber and How Does It Work

What is Rotary Scrubber and How Does It Work Vibrating Screen Mesh Types

Vibrating Screen Mesh Types Polyurethane Screen Panel | Features & Benefits

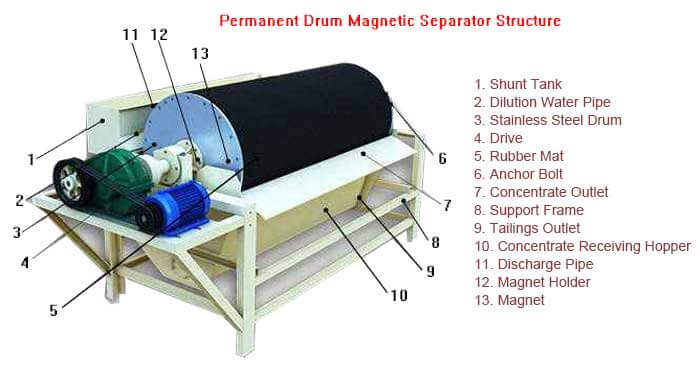

Polyurethane Screen Panel | Features & Benefits What is Permanent Magnetic Drum Separator | How Does It Work

What is Permanent Magnetic Drum Separator | How Does It Work

I am looking trommel screen for segregation of material of different sizes ( min 4). Maximum feed input 40 kg ( coal, iron ore, lime stone etc). Cycle shall be repeated once screen of same shall be completed.

Due to limitations in space we are looking for parallel screening drum type trommel screen.

Kindly connect with me.

Hello. I am interested in your product

I am looking for more details about trommel screen 80tph

Thanks for your inquiry trommel screen, Our Trommel Screens are highly efficient in the separation and processing of wood chips, top soil, compost, light demolition waste and domestic waste.

Can you tell more about your materials?

Could you help me please? I need to know how can I design a Trommel screen for 1ton capacity… Diamater and lenght. Thank you

Our trommel rotary screens are mainly used in the following aspects:

1. It is used for sand screening in sand plant;

2. Used as sand screening machine to screen sand and stone;

3. Used as gold washing equipment for screening and cleaning sand, stone and gold;

4. Used for screening mineral materials in gold boat.