Vibrating Screen Mesh Types

Vibrating screen mesh as the main vulnerable parts of the vibrating screen, which is in direct contact with the materials in the production process. Once the screen mesh is not selected properly, it is easy to be damaged.

At present, the vibrating screen meshes are mainly divided into metal and non-metal. Metal vibrating screen meshes include low-carbon, high-carbon, high-manganese steel and stainless screen mesh, etc., while non-metallic vibrating screen meshes mainly include rubber, nylon and polyurethane screen mesh etc.

Polyurethane Screen Mesh

The composition material of polyurethane screen mesh is polymer organic elastomer, which has excellent wear resistance, flex resistance and large load-bearing capacity, and has been specially treated to ensure that it will never be delaminated under long-term alternating load.

The bearing capacity of polyurethane screen mesh is higher, which is more than 2.5 times that of rubber screen mesh, and its service life is 8-10 times longer than that of ordinary metal screen mesh, 3 times that of stainless steel screen mesh and 3.9 times that of natural rubber.

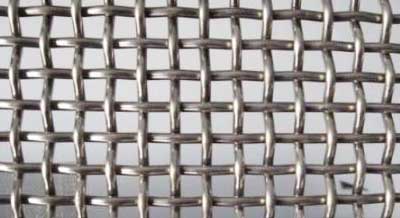

Manganese Steel Mesh

Manganese steel screen mesh is a kind of screen product woven with 1.6mm-12mm manganese steel wire, which adopts embedded knitting method, the intersection of warp and weft is not prominent, the screen surface is flat, the force is uniform, it has good plasticity and toughness, it can achieve better service effect, and the service life is more guaranteed at the same time.

High manganese steel has high strength, stiffness and bearing capacity, and its service life can reach 8 times that of ordinary screen mesh. It is mostly used in large mining industry, and can also be used as protective net in drum screen, electromagnetic high frequency vibrating screen machine and asphalt mixer.

Stainless Steel Mesh

The main materials of stainless steel screen mesh are 201, 301, 302, 304, 304L, 316, etc., which have the advantages of good acid resistance, alkali resistance, corrosion resistance, high strength, strong tension, toughness and wear resistance.

Stainless steel screen mesh is often used for screening and filtration in acid and alkali environment, as well as in petroleum industry and chemical fiber industry.

Welded Screen Mesh

The welded screen is welded from the raw material of high manganese steel, which is the same as the raw material of manganese steel screen mesh, but the processing technology is quite different.

The production of welded screen mesh is very different from the traditional woven wire vibrating screen mesh, and its service life is 3-5 times that of ordinary manganese steel screen mesh.

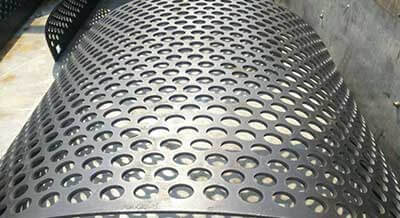

Perforated Screen Mesh

Perforated screen mesh refers to the use of a punch to punch out the target pattern in the screen plates to be processed, generally made of stainless steel, aluminum plate, hot and cold steel plate, copper plate, PVC plate and other materials, with many hole selectivity, such as long hole, square hole, round hole, hexagonal hole, fish scale hole, stretch special-shaped hole and so on.

Perforated screen mesh has the characteristics of light weight, anti-skid, beautiful and generous, good filtration performance and so on. It is often used in grinding screen, ore screen and so on.

PU Screen Panel vs Rubber Screen Panel

PU Screen Panel vs Rubber Screen Panel Polyurethane Screen Panel | Features & Benefits

Polyurethane Screen Panel | Features & Benefits Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Top 10 Vibrating Screen Types & Working Principle [How To Choose] 5 Tips of Vibrating Screen Problems & Solutions

5 Tips of Vibrating Screen Problems & Solutions