Why Use Frac Sand & How To Choose The Right Frac Sand

Why Frac Sand So Popular In Oil Industry

Why do Americans like to use so much silica sand in the field of oil and gas? To answer this question, you need to understand fracturing.

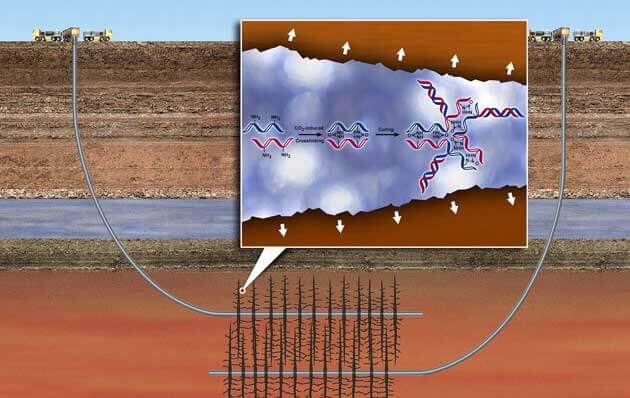

In the oil(petroleum) field, fracturing refers to the use of hydraulic action to make oil and gas reservoirs form fractures in the process of oil or gas production, also known as hydraulic fracturing.

Hydraulic fracturing technology means that in the case of high pressure, the fracturing fluid is pumped into the oil well, resulting in high pressure at the bottom of the well. when the pressure is enough to fracture the rock, the formation will form fractures and expand forward to a certain space. In order to keep the fracture open, the proppant should be filled with the fracturing fluid in the fracture after fracturing. After the proppant is transported, the viscosity of the fracturing fluid is reduced and refluxed, so that cracks with high conductivity are produced.

At present, the oil fracturing proppants used in the world can be divided into 3 types: silica frac sand, ceramsite proppant and film-coated proppant.

In recent years, with the continuous downturn of oil and gas prices, reducing costs and increasing efficiency has become the main theme of oil and gas development. In addition to increasing drilling speed and increasing efficiency, North America has greatly reduced the amount of ceramsite and the cost of fracturing materials, considering fracturing cost and economic effect. Frac sand proppant plays a leading role in the application.

The content of SiO₂ in quartz sand is closely related to its particle size. Usually, the larger the particle size is, the higher the SiO₂ content is. The content of SiO₂ in silica sand used as a proppant is usually about 80%, while the content of SiO₂ in some high-quality silica sand is as high as 98%.

Because of the different applications, the content of SiO₂ in frac sand is not the main factor. So how to choose a good frac sand? There are 6 tips below need to note.

How To Choose The Right Frac Sand

1. Sphericity and Roundness

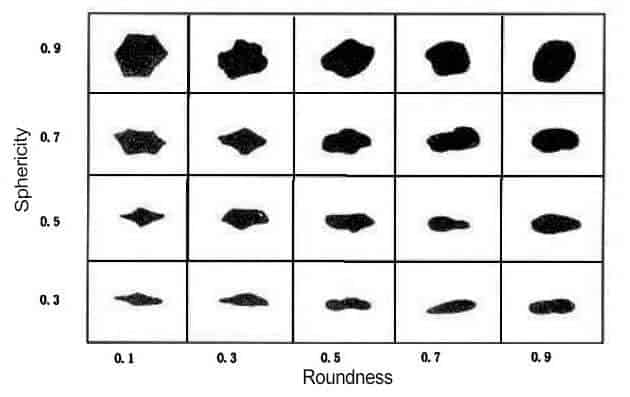

Sphericity refers to the degree to which the fracturing proppant (fracturing sand) is close to spherical. Roundness refers to the “Round Degree” of frac sand particles, the more edges and corners of frac sand particles, the worse the roundness; on the contrary, the edges and corners are smooth, the roundness is good. Similar size round grains can ensure consistent permeability, thus providing greater fracture conductivity.

The sphericity and roundness of natural frac sand should not be ≤ 0.6. In the actual testing, the proppant sphericity and roundness are tested with the proppant sphericity and roundness chart, as shown in the following figure.

2. Acid Solubility

2. Acid Solubility

Acid solubility refers to the proportion of the mass of proppant dissolved by acid in acid solution.

Acid resistance is an important index of fracturing proppant. The proppant with good acid resistance can work in acidic strata for a longer time and maintain good conductivity. The allowable acid solubility values of various particle size proppants are shown in the table below. It is worth noting that the acid solubility standards of frac sand and ceramsite proppants are the same.

3. Turbidity

The turbidity of proppant refers to the degree of turbidity of the liquid after a certain mass of proppant is added to the distilled water of a specified volume, shaken and placed for a certain period of time, in FTU.

Turbidity describes the surface finish of the proppant. According to the standards, the frac sand turbidity should be ≤ 100FTU. This can be solved by washing during processing.

4. Crush Resistance

Crush resistance is the crushing rate determined by the pressure test of a certain amount of fracturing sand proppant under rated pressure. The main factors affecting the crushing rate are roundness, sphericity, surface finish, microstructure etc.

The crushing rate of frac sand proppant affects the fracture conductivity. American Petrleum Institute(API) requires frac sand to withstand stress of 4,000–6,000 psi.

5. Size

The size of the frac sand proppant is related to the viscosity of the fluid system and its ability to transport sand into the fracture, and the size range of the proppant is very important. Typical frac sand proppant sizes are usually between 20 – 140 mesh (106μm – 850μm), for example, 20 – 40 mesh (420μm – 840μm), 40 – 70 mesh (212μm – 420μm) or 70 -140mesh (106μm – 212μm).

Different specifications are selected according to the depth of the well. 1 mesh refers to the number of emptiness on the screen per square inch, and the higher the number of mesh, the smaller the particle size that can pass through the screen.

6. Proppant Density

The density of frac sand proppant is the mass of proppant per unit volume (g/cm ³), which describes the overall density of the proppant accumulation. The main factors affecting the density are roundness, sphericity, surface finish and so on. The density of oil fracturing sand is low, which is easy to pump downhole. If the density is high, it is difficult to suspend in the fracturing fluid and fill in the fracture.

What is Frac Sand & How Frac Sand is Processed

What is Frac Sand & How Frac Sand is Processed Hot 3 Types of Oil Fracturing Proppants | Features

Hot 3 Types of Oil Fracturing Proppants | Features 5 Differences Between Sea Sand and River Sand

5 Differences Between Sea Sand and River Sand What is Quartz Sand | How Many Types of Quartz Sand

What is Quartz Sand | How Many Types of Quartz Sand