What is Frac Sand & How Frac Sand is Processed

What is Frac Sand

Frac sand is a kind of high-purity quartz sand with super compression resistance and high roundness. Generally, frac sand is finely processed from natural quartz sand through multiple processes. It is mainly used in the field of petroleum industry, especially in the application of hydraulic fracturing. That is, high-pressure water pump is used to inject fracturing fluid into the oil and gas reservoir and crush the reservoir to obtain oil and gas resources.

Frac sand is called “proppant” because it supports fracture opening by forming a pore space network, enabling oil fluid to flow out of the rock and into the well. Although other types of proppants are available, frac sands are unique in their compressive fragility and very circular particle shape, which makes them very suitable for use in the fracturing process.

In the petroleum field, fracturing refers to a method of using hydraulic action to form fractures in oil and gas reservoirs in the process of oil or gas production, also known as hydraulic fracturing. Hydraulic fracturing technology refers to pumping fracturing fluid into the oil well under high pressure, resulting in high pressure at the bottom of the well. When the pressure is enough to fracture the rock formation, the formation will generate fractures and expand forward into space. In order to keep the fracture open, proppant should be filled in the fracture with fracturing fluid after rock fracture. The product specifications of petroleum frac sand include: 20-40 mesh, 40-70 mesh and 70-140 mesh.

Frac Sand Types

- Quartz Sand

- Metal Aluminum Balls

- Walnut Shells

- Glass Beads

- Plastic Balls

- Steel Balls

- Ceramic Particles

- Resin Coated Sand

At present, the oil fracturing proppants used internationally are generally divided into 3 types: quartz sand, ceramsite proppants, and coated proppants. In the construction of shale gas fracturing in North America, the proportion of ceramsite proppant used is gradually decreasing. Considering the cost and economic benefits of fracturing, quartz sand proppant plays a dominant role in application.

How Frac Sand is Processed

Frac sand production process includes: Raw Materials – Sizing – Magnetic Separation – Scrubbing – Drying & Screening – Solid Waste Management. Frac sand production equipments include: silo, vibrating feeder, vibrating screen, magnetic separator, silica scrubbing machine, dryer, square swing screen, thickener and box filter press.

- Sizing: firstly, the fracturing sand is stored in the silo and screened by linear vibrating screen. After screening, it is extracted separately for > 20 purposes.

- Magnetic Separation: magnetic separation through magnetic separator for < 20 purposes,

- Scrubbing: the scrubbing machine performs strong cleaning, and then enters the sand washing machine for cleaning and dehydration. It is separated by the impeller separator, and then enters the lower dehydration screen for dehydration treatment.

- Drying & Screening: the cleaned fracturing sand enters the dryer for drying, and then enters the square swing screen for fine screening.

- Solid Waste Management: the overflow slurry in the washing process enters the thickener for clean water recovery. 80% of the wastewater can be recovered in this process, and the underflow of the thickener enters the filter press for treatment into mud cake.

Frac Sand Performance Requirements

1. Frac sand shall have sufficient compressive strength and wear resistance, be able to withstand strong pressure and friction during injection, and effectively support artificial fractures.

2. The relative density of fracturing sand particles should be low to facilitate pumping into the well.

3. Under the condition of 200 ℃, the frac sand particles have no chemical interaction with fracturing fluid and reservoir fluid, and the acid solubility is less than 7%.

4. Frac sand particles are relatively uniform, and different sizes are not allowed.

Why Use Frac Sand & How To Choose The Right Frac Sand

Why Use Frac Sand & How To Choose The Right Frac Sand Hot 3 Types of Oil Fracturing Proppants | Features

Hot 3 Types of Oil Fracturing Proppants | Features Silica Sand Washing Plant | Quartz Sand Processing

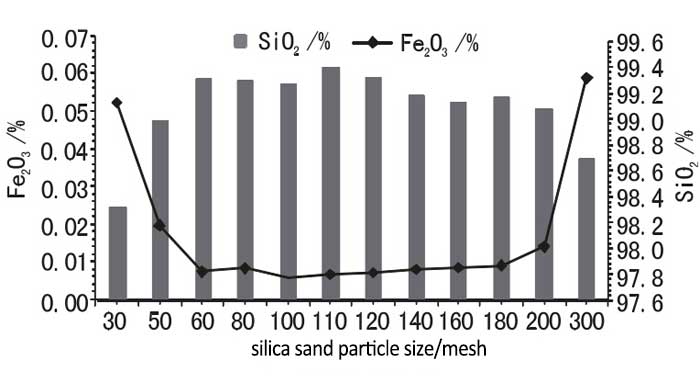

Silica Sand Washing Plant | Quartz Sand Processing 8 Methods for Removing Iron From Silica Sand

8 Methods for Removing Iron From Silica Sand