8 Methods for Removing Iron From Silica Sand

Silica sand is a non-metallic mineral with a wide range of applications, including traditional fields such as glass products, building materials, waterproof and anti-corrosion materials, as well as high-tech industries such as electronic materials, optical fiber communication, SiO₂ film materials, etc.

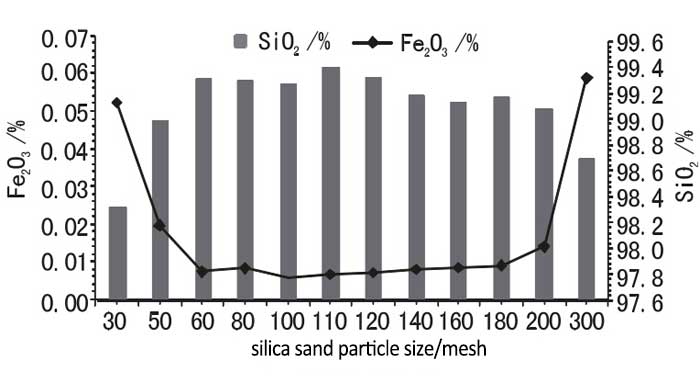

The high-tech industry has very strict requirements for the purity of silica sand, generally requiring a SiO₂ content greater than 99% 99%, impurities, especially iron, are limited to a very low range in order to improve their value. Therefore, it is necessary to remove iron from silica sand.

The Forms of Iron Impurities In Silica Sand

The occurrence of iron impurities in silica sand is complex and diverse, either existing in mineral phases such as clay or feldspar, adhering to the surface of particles in the form of iron oxide or iron containing minerals, or occurring inside quartz particles.

| Silica Sand Type | K₂O | Na₂O | CaO | MgO | Fe₂O₃ | Al₂O₃ | MnO | Total Content |

| -200 – 300 mesh | 0.03 | 0.01 | 0.02 | 0.02 | 0.02 | 0.18 | 0.001 | 0.29 |

| – 300 mesh | 0.19 | 0.06 | 0.17 | 0.02 | 0.06 | 0.67 | 0.001 | 1.17 |

(1) Existing in Clay Minerals

In some exposed sedimentary sand deposits, there is a significant amount of weathered clay. This type of clay is weathered from feldspar, limestone, shale, and other materials. The composition of clay is a natural hydrated bauxite silicate containing a mixture of mica, quartz, limonite, chlorite, calcite, and hornblende. Its particle size is very fine, mainly composed of 10 μ Particle composition below m.

(2) Exists in Heavy Minerals and Mmagnetic Minerals

Heavy minerals refer to minerals with a relative density greater than 2.9. Most of these minerals have magnetism or weak magnetism, and iron is the basic constituent element in these minerals. So we can also refer to them as existing in individual minerals such as magnetite, hematite, pyrite, pyrrhotite, ilmenite, chromite, olivine, olivine, and limonite.

(3) Exists in light Minerals

Light minerals mainly refer to feldspar (usually orthoclase or plagioclase). Aluminum oxide in feldspar is sometimes replaced by iron oxide, with an amount of up to 0.5% -0.7%. In addition, there are also kaolinite, muscovite, calcite, dolomite, etc. Among these light minerals, iron enters the lattice in the form of isomorphism, and due to their density being very close to quartz, it is quite difficult to separate them.

(4) Existing in Thin Film Iron

The quartz particles in silica sand appear white in pure conditions, but gray, brown, yellow, and even red after being contaminated. For example, clay can make it gray or yellow, metal minerals and other dark minerals can make it gray, and thin film iron can make it yellow or red. What we usually see are mostly contaminated silica sand.

The contamination of quartz particles by clay minerals is related to the surface depressions and crevices of quartz, as well as the plasticity of clay. This kind of clay attached to the surface of quartz particles is relatively easy to remove because they are not firmly bonded. However, it is difficult to eliminate the iron oxide film on the surface of quartz particles, which is caused by mineralization.

(5) Exist in a Continuum or lattice

The various minerals in silica sand can be considered to be in a state of individual dissociation, so there is no need for further crushing. However, the situation where quartz particles are connected with other iron containing minerals still exists. These connected bodies are mostly dark minerals, some of which are encapsulated inside quartz particles, while others are embedded at the edges of quartz particles, forming mineral aggregates.

8 Methods for Removing Iron From Silica Sand

1. Water Washing for Iron Removal

Water washing for iron removal is the use of hydraulic flushing to remove iron impurities from silica sand. During the flushing process, by controlling the intensity and direction of water flow, iron impurities on the surface of silica sand particles are washed down, thereby achieving the goal of iron removal.

The application of silicon sand water washing technology for iron removal is mainly suitable for silicon sand with high iron content, especially for silicon sand containing a large amount of clay minerals. By using water washing to remove mud and iron, the iron content in silica sand can be effectively reduced, and the quality and value of silica sand can be improved.

2. Gravity Separation for Iron Removal

Silica sand gravity separation for iron removal is a method of separating iron impurities and the difference in specific gravity of silicon sand. This technology mainly uses equipment such as shaking tables and chutes for ore dressing, and uses hydraulic action to separate silicon sand and iron impurities.

The gravity separation iron removal technology is a relatively simple and low-cost iron removal method, but the iron removal effect is generally low and needs to be combined with other iron removal methods.

The iron removal machinery of the gravity separation method mainly includes sprial chutes, shaking tables, and Jig Machine

3. Mechanical Scrubbing for Iron Removal

Mechanical scrubbing is the process of removing thin films of iron and iron containing minerals adhering to the surface of silica sand through the collision and friction between mechanical external forces and sand particles.

At present, scrubbing technology mainly includes rod grinding scrubbing and mechanical scrubbing. For mechanical scrubbing, it is generally believed that the main factors affecting the scrubbing effect are the structural characteristics and configuration form of the scrubbing machine, followed by process factors, including scrubbing time and scrubbing concentration. The efficiency of mechanical cleaning increases with the increase of slurry concentration, as increasing slurry concentration can increase the probability of particle collision.

Compared with other iron removal processes, this method has the following characteristics:

- The product quality is good. It can meet the quality requirements of high-quality silica sand for float glass;

- Large output. Nowadays, silica sand plant use this method to remove iron more often because of its low cost and simple operation, but the iron removal rate is relatively low.

The recommended equipment for scrubbing methods include rod mills, attrition scrubbers, etc.

4. Magnetic Separation for Iron Removal

The main mineral in silica sand – quartz, is an diamagnetic substance that cannot be magnetized in a magnetic field. The impurity minerals containing iron in silica sand, such as hematite, limonite, magnetite, and goethite, are mostly magnetic substances that can be magnetized in a magnetic field. In magnetic separation technology, this property difference is utilized to remove these iron containing impurity minerals from silica sand through magnetic separation.

Magnetic separation is divided into dry separation and wet separation. Wet strong magnetic separation has defects such as high power consumption of magnetic separators, easy wear of media, high production water consumption, and high operating and maintenance costs. The dry strong magnetic separation process is easy to operate and has lower operating and maintenance costs compared to wet methods.

In the magnetic separation process, the wet strong magnetic separator can maximally remove weak magnetic impurities such as hematite, limonite, and biotite, including connected particles.

For silica sand mainly composed of weakly magnetic impurity minerals, a wet strong magnetic machine can be used to select at least 10000 Ostros; For strong magnetic minerals containing impurities mainly magnetite, the selection effect is better using weak or medium magnetic machines.

The recommended equipment for magnetic separation method includes: magnetic drum, magnetic separator, high gradient magnetic separator, etc.

5. Ultrasonic Iron Removal

When ultrasound is emitted in water (or solution), it generates many compression and expansion areas, leading to the formation and rupture of countless microbubbles (cavitation bubbles), which is called cavitation phenomenon.

During the cavitation process, the internal pressure of the liquid undergoes a sudden change, accompanied by shock waves, which can reach pressures of several thousand to tens of thousands of atmospheres. Under the action of this shock wave, iron containing impurities adhering to the surface of the particles fall off and enter the liquid phase, thereby achieving the goal of removing iron.

Compared with mechanical scrubbing, ultrasonic iron removal not only eliminates surface impurities of minerals, but also removes impurities at the cleavage gaps of particles, resulting in a better iron removal effect.

6. Flotation Iron Removal

The flotation method is mainly used to separate feldspar from silica sand, and can also be used to remove clay minerals such as mica and secondary iron from silica sand.

The flotation method can be divided into 3 types:

- Fluorine and acid method. This method is widely adopted due to its good flotation effect, easy control, and stable indicators. However, fluoride ions have a significant impact on soil erosion and damage to the surrounding ecological environment.

- Fluoride free and acid method. The biggest advantage of this method is to avoid the use of fluoride ions that have a destructive effect on the environment, and the production indicators are stable. However, the corrosive effect of strong acids on mineral processing equipment cannot be ignored. There are high requirements for flotation equipment.

- Fluoride free and acid free method. Under natural pH conditions, a unique high concentration slurry flotation environment is created by the rational allocation of anionic and cationic collectors, achieving the goal of prioritizing the flotation of impurity minerals.

The flotation method for iron removal is simple, cost-effective, and effective. The recommended equipment for flotation method is flotation machine and stirring tank.

7. Acid leaching for Iron Removal

Acid leaching for iron removal utilizes the characteristic that quartz is insoluble in acid (excluding HF), and impurity minerals containing Fe can be dissolved by acid solution, thus achieving the goal of removing iron containing minerals from silica sand. The acid leaching method can not only remove iron containing minerals from silica sand, but also has good removal effects on non-metallic impurity minerals in quartz.

The recommended equipment for acid leaching method is a leaching stirring tank.

8. Biological Iron Removal

The use of microorganisms to remove thin film iron or impregnated iron on the surface of silica sand particles is a newly developed iron removal technology.

According to research, microorganisms such as Aspergillus niger, Penicillium, Aspergillus pyriformis, Pseudomonas aeruginosa, Bacillus subtilis, and Lactobacillus have achieved good results in removing iron oxide on the surface of quartz. Among them, Aspergillus niger has the best effect in removing iron, with the highest removal rate of Fe2O3 reaching 88.8%. The grade of Fe2O3 in silica sand is as low as 0.008%.

Silica Sand Washing Plant | Quartz Sand Processing

Silica Sand Washing Plant | Quartz Sand Processing Analysis of 8 Whitening Methods for Kaolin

Analysis of 8 Whitening Methods for Kaolin Silica Sand Processing Solutions

Silica Sand Processing Solutions 5 differences between Silica Sand and regular Sand

5 differences between Silica Sand and regular Sand