5 differences between Silica Sand and regular Sand

Silica sand is a type of sand that is composed of silicon dioxide or SiO2. It is a mineral that is abundantly found in nature and one of the most common minerals on the earth’s surface and is found in rocks like granite, gneiss, and sandstone. Here are some of the features of silica sand:

- High Purity: Silica sand has a high degree of purity, with few impurities, making it ideal for use in many industrial applications.

- Consistent Size: The size of silica sand particles is consistent and ranges between 0.5 mm to 0.1 mm in diameter.

- High Melting Point: Silica sand has a high melting point of around 1700°C, making it suitable for use in high-temperature applications.

- Hardness: Silica sand is a hard material with a Mohs hardness of 7, which means it can scratch glass and other materials.

- Low Conductivity: Silica sand is a poor conductor of electricity and heat, making it useful for insulation and refractory materials.

- Abrasive: Silica sand is a good abrasive material and is commonly used in sandblasting operations to remove paint or rust from surfaces.

- Chemical Resistance: Silica sand is resistant to most chemicals and does not react with them, making it useful in various chemical processes.

These features make silica sand a versatile material that finds widespread applications in various industries, including construction, glass manufacturing, foundry, ceramics, and water filtration.

In this article, we will explore the differences between silica sand and regular sand.

1. Composition

Silica sand is composed of almost pure quartz grains, while regular sand is composed of a mixture of minerals such as feldspar and mica, along with some organic materials. This makes silica sand more uniform in terms of its composition, size, and shape.

2. Purity

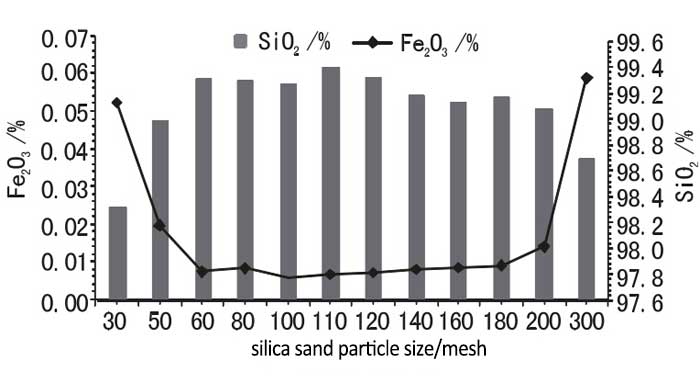

Silica sand is much purer than regular sand because of its mineral composition. It contains high levels of silica, which can range anywhere from 95% to 99%. On the other hand, regular sand can contain impurities, such as clay, silt, or other minerals that affect its purity.

3. Uses

Silica sand is used for various industrial purposes, such as manufacturing glass, producing electronics, casting metals, drilling for oil and gas, and filtration of water. It is also used for construction and landscaping purposes. On the other hand, regular sand is mostly used for construction, including the making of concrete, mortar, and bricks.

4. Durability

Silica sand is more durable than regular sand due to its hardness, which ranges from 7 on the Mohs scale to 9. Regular sand has a lower hardness level, ranging from 1 to 3 on the Mohs scale. This difference makes silica sand more resistant to abrasion and erosion, making it ideal for industrial and construction uses.

5. Cost

Silica sand is generally more expensive than regular sand because of its higher purity levels and specialized applications. Regular sand is much cheaper, making it more accessible and widely used in construction projects.

In conclusion, the main differences between silica sand and regular sand are their composition, purity, uses, durability, and cost. Silica sand’s unique properties make it ideal for various industrial applications, making it more expensive compared to regular sand that is primarily used for construction. Understanding these differences can help in making informed decisions when choosing the type of sand for a specific project.

How To Make Glass From Silica Sand

How To Make Glass From Silica Sand Silica Sand Processing Solutions

Silica Sand Processing Solutions Silica Sand Washing Plant | Quartz Sand Processing

Silica Sand Washing Plant | Quartz Sand Processing 8 Methods for Removing Iron From Silica Sand

8 Methods for Removing Iron From Silica Sand

Dear Sir/Miss;

We kindly request a quotation for the following Silica products.

1- Silica sand :0-2-0-5 mm(or similar)

2- Silica sand :2-5 mm(or similar)

3- Silica Powder :800 mesh mm(or similar)

Actually we are going to mix them with cements.

If sizes are unavailable, Please provide pricing for the closest alternatives.

best regards

Amir

My Phone:(703)397-6792

My Email:ttechno1401@gmail.com