Top 10 Crusher Machine Working Principle

Common Crusher Working Principle and GIF:

1. Jaw Crusher

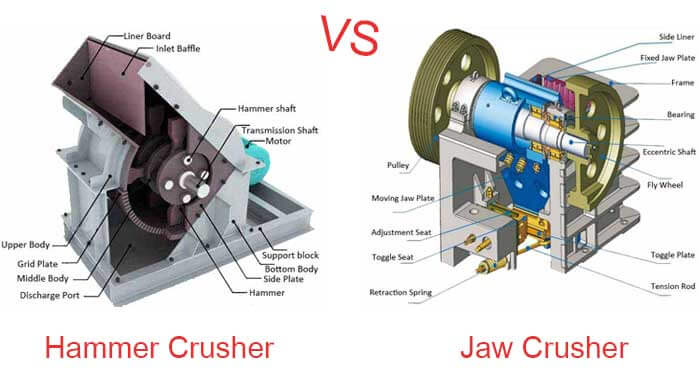

The jaw crusher consists of two jaw plates, a moving jaw and a stationary jaw, forming a crushing chamber. It simulates the movement of the two jaws of animals and completes the material crushing operation.

The jaw crusher has a high crushing ratio, uniform product particle size, simple structure, reliable operation, easy maintenance, and economical operating costs.

2. Cone Crusher

Both cone crushers and jaw crushers are extrusion crushers, but their working principles are different. Cone crushers rarely achieve material crushing through the cooperation of moving and fixed cones.

The cone crusher has large crushing force, high efficiency, high processing capacity, low operating cost, convenient adjustment, practicality and economy. The particle size of the crushed products is uniform, and the service life is long.

3. Impact Crusher

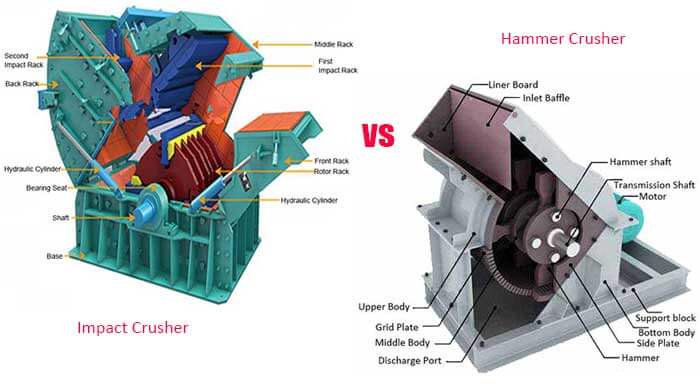

An impact crusher is a process in which a material is subjected to two or more impacts in a vortex crushing chamber, resulting in the entire crushing process. Materials are broken by mutual self impact.

The impact crusher has low energy consumption, high output, small equipment volume, simple operation, and convenient installation and maintenance. During the production process, stones can form a protective layer, and the body is wear-resistant and durable.

4. Counterattack Crusher

A counterattack crusher is a crushing machinery that uses impact energy to crush materials. The characteristics are novel structure, stable operation, low energy consumption, high output, stable operation, multi chamber uniform crushing, suitable for crushing hard rocks, convenient use and maintenance, and the ability to selectively crush.

5. Hammer Crusher

A hammer crusher is a type of crusher that breaks the material loaded into the machine when it enters the rotary table for rotation due to centrifugal and rotational forces.

The hammer crusher has a simple structure, small self weight, high productivity, small and uniform particle size of the product, and fewer excessive crushing phenomena.

6. Vertical Crusher

Material enters the vertical crusher chamber and is struck by a high-speed rotating plate hammer, hitting the toothed impact plate on the first impact plate at the top of the crushing chamber before rebounding and entering the second crushing chamber. Under the action of wear-resistant tooth plates and plate hammers, enormous pressure, bending force, and friction force are generated. The material is thoroughly finely ground in this crushing chamber and discharged from the body.

The vertical crusher has a simple and reasonable structure, low operating cost, low wear, high crushing rate, and has the functions of fine crushing and coarse grinding.

7. Roller Crusher

Roller crusher, also known as double roller crusher, when the material enters between two rollers, due to the effect of friction, the ore is carried into the crushing space between the two rollers, compressed and crushed.

The roller crusher has a simple structure, occupies small space, and is easy to operate and maintain. Internally equipped with dust-proof plates, with good sealing performance, it avoids the splashing of small materials after crushing, reduces dust, reduces working noise, and greatly improves the working environment.

8. Toothed Roller Crusher

The toothed roller crusher adopts a special wear-resistant toothed roller for high-speed rotation to split and crush materials, forming a high productivity mechanism.

The toothed roller crusher has dual functions of screening and crushing, adopts dual overload protection, flexible assembly, convenient maintenance, reasonable structure, and long service life.

9. Double Roll Crusher

The double roll crusher uses the friction between the material and the rollers to roll the incoming material into the crushing chamber formed by the two rollers for crushing.

The discharge particle size of the double roll crusher can be adjusted freely, with small footprint, no installation restrictions, high production capacity, and low operating costs.

10. Single Roll Crusher

The crushing of materials in a single roll crusher is a process of splitting and squeezing. When the material enters the single roll crusher from the feeding port above, it is carried by the rotating roller into the gap between the stick and the jaw plate for crushing. The crushed material is discharged under its own weight.

The main structure of a single roll crusher includes a toothed rotating roller and an adjustable jaw plate. By adjusting the gap between the jaw plate and the roller, the particle size of the crushed material can be controlled. The single roll crusher is mainly used to crush brittle materials with a stress of less than 20kN/cm2, and the particle size after crushing is ≤ 25mm.

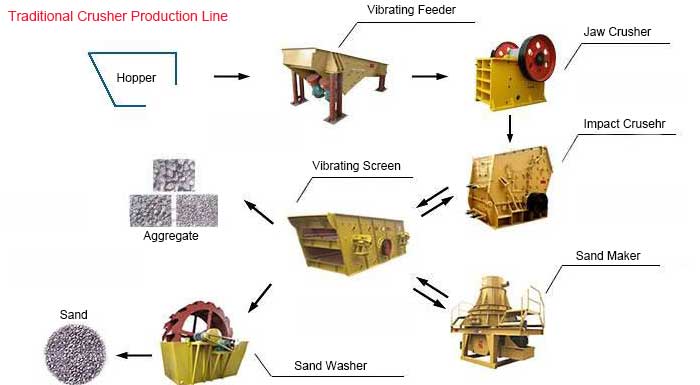

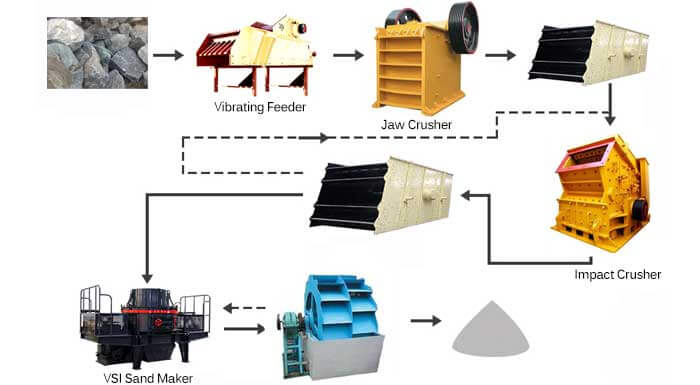

Traditional crushing production line is generally composed of vibration feeder, jaw crusher, third generation sand making machine (fine crusher), sand washing machine, vibration screen and belt conveyor.

According to different process requirements, various types of equipment are combined to meet different production requirements.

Jaw Crusher Working Principle | Applications| Benefits

Jaw Crusher Working Principle | Applications| Benefits VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications Hammer Crusher VS Jaw Crusher

Hammer Crusher VS Jaw Crusher Impact Crusher VS Hammer Crusher [7 Pics & 10 Tips]

Impact Crusher VS Hammer Crusher [7 Pics & 10 Tips]

I’m very interested an I know hammer crusher and how crusher

guys i need technical support for iron ore crushing plant. please contact me for a paid consultation agreement.

i want the best result with best cost effective investment.

Ok sir, i will contact you for more about how to set up a crushing plant

very useful contents… thank you