Filter Press [Definition, Components, Types & Comparison]

Filter Press Definition Components & Types [PDF DOWNLOAD]

What is a Filter Press

Filter Press is a kind of mechanical dewatering equipment which uses special filter mediums to exert certain pressure on the solid liquid mixture to make the liquid filtering out.

Filter Press is low energy consumption, low agent dosage, high separation efficiency and high solid content of mud cake, which makes filter press a widely used dewatering machine in mining, coal washing, metallurgy, paper making, medicine, food, chemical industry, sewage treatment and other industries.

Filter Press Components

Frame

Frame is the supporting component of a filter press. The thrust plate and compression plate are at both ends and the beam connect the two parts. The beams are used to support the filter plate, filter frame and the compression plate.

(i). Thrust plate

Thrust plate is connected with the support to place the filter press on the foundation. In the middle of the thrust plate of the chamber filter press, there are feed holes, 4 holes in the four corners. The holes in the upper two corners are the inlet of washing liquid or pressing gas, and the outlet in the lower two corners (undercurrent structure or filter outlet).

(ii). Compression plate

Compression plate is used to compress the filter plate and frame, and the rollers on both sides are used to support the rolling of the compression plate on the rail of the beam.

(iii). Beam

It is a load-bearing component. According to the requirements of environmental protection, rigid polyvinyl chloride, polypropylene, stainless steel or new anti-corrosion coatings can be selected to coat.

Compression Devices

Manual compression, mechanical compression, hydraulic compression.

(i). Manual Compression

Screw type mechanical jack is used to push the compaction plate to press the filter plate.

(ii). Mechanical Compression

Mechanism compression devices consists of motor (equipped with advanced overload protector) reducer, gear pair, screw and fixed nut. When pressing, the motor rotates forward to drive the reducer and gear pair, so that the screw rod rotates in the fixed screw mother, and pushes the compressing plate to press the filter plates and the filter frames tightly.

(iii). Hydraulic Compression

Hydraulic compression devices consists of hydraulic station, cylinder, piston and piston rod. When the hydraulic pressure is pressed mechanically, the high pressure oil is supplied by the hydraulic station, and the component chamber composed of cylinder and piston is filled with oil. When the pressure is greater than the friction resistance of the pressure plate, the pressure plate slowly compresses the filter plate.

Filtration Devices

The filteration devices consists of filter plates, filter frames, filter cloths and filter press diaphragms. The two sides of the filter plate are covered by filter cloths. When a filter press diaphragm is needed, a set of filter plates are composed of a diaphragm plate and a side plate.

(i). Filtering Types

The types of filtrating is divided into open-flow filtrating and underflow filtrating.

A. Open-flow Filtrating: The outlet hole under each filter plate is equipped with a water nozzle, and the filtrate flows intuitively from the water nozzle.

B. Underflow Filtrating: There are outlet holes under each filter plate. The outlet holes of several filter plates are connected to form an outlet channel, which is discharged by the pipeline connected with the outlet holes under the thrust plate.

(ii). Washing Methods

When filter cake needs washing, there are Open-flow unidirectional washing and bidirectional washing, Undercurrent-flow unidirectional washing and bidirectional washing.

A. Open-flow Unidirectional Washing is that the washing liquids enter from the washing holes of the thrust plate in turn, passes through the filter cloths and then pass through the filter cakes, and flow out from the filter plates.

B. Open-flow Bidirectional Washing is that the washing liquids enter the holes on both sides of the thrust plate twice, that is, the washing liquids washing from one side firstly and then washing from the other side. The outlet of the washing liquids is diagonal to the inlet, so it is also called bidirectional cross washing.

C. Undercurrent-flow Unidirectional Washing is that the washing liquids enter the filter plates in turn from the washing liquids of the thrust plate, passes through the filter cloths and then through the filter cakes, and then flow out from the non-orifice filter plates.

D. Undercurrent-flow Bidirectional Washing is that the washing liquids enter two holes on both sides of the top of the stopping plate and then wash twice. That is to say, the washing liquids washes from one side and then washes from the other side. The outlet of the washing liquids is diagonal, so it is also called undercurrent bidirectional cross washing.

(iii). Filter Cloth

Filter cloth is a main filter medium. The selection and use of filter cloth plays an important role in the filtering effect. When selecting, appropriate filter cloth material and aperture shall be selected according to the pH value of filter materials, solid particle size and other factors to ensure low filtering cost and high filtering efficiency. When using, the filter cloth shall be smooth without discount and aperture unblocked.

Filter Press Types

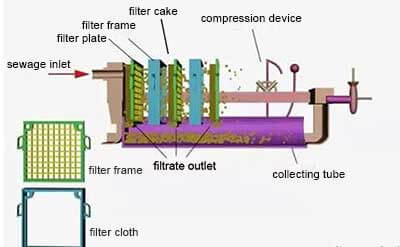

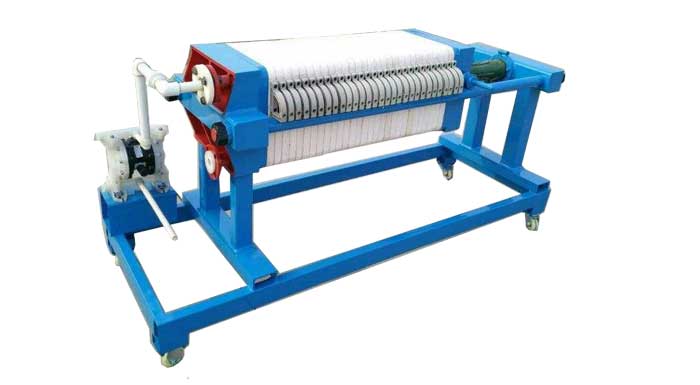

Plate and Frame Filter Press

Plate and frame filter press consist of alternately arranged filter plates and frame to form a set of filter chambers. The surface of the filter plate is grooved, and the protruding part of the filter plate is used to support the filter cloth. The edge and corner of the filter frame and the filter plate have through holes, which form a complete channel after assembly, and can enter suspension, wash water and drain filtrate. Each side of the plate and the frame has a handle supported on the cross beam, and the plate and the frame are pressed by the compression device. The filter cloth between the plate and the frame acts as a sealing gasket.

When working, the slurry is pumped into the filter chamber by the feed pump to form filter cake on the filter cloth until the filter chamber is filled. The filtrate passes through the filter cloth and flows along the filter plate groove to the channel at the edge and corner of the plate and frame, and is discharged centrally. After filtering, the filter cake can be washed with clean water. After washing, compressed air is sometimes introduced to remove the remaining detergent. Then open the filter press to remove the filter cake, clean the filter cloths, re-press the plate and frame, the next filter cycle is started.

Plate and frame filter press is suitable for slurry with high compressibility or near incompressibility of filter residue. The suitable concentration of solid particles in suspension is < 10%, and the operating pressure is 0.3-0.6 MPa. The filter area can be increased or decreased with the number of filter plates used. The plate frame is usually square, the inner edge of the filter frame is 200-2000 mm long, the thickness of the frame is 16-80 mm, and the filtering area is 0.5-1200 square meters.

Chamber Filter Press

The structure and working principle of the chamber filter press are similar to that of the plate and frame filter press. The difference is that the two sides of the filter plate are concave. Each two plates are combined into a chamber-shaped filter chamber, omit the filter frame, There is a circular hole in the center of the filter plate from which the slurry flows into each filter chamber. Chamber filter press is suitable for slurry that need to be filtered under high pressure without washing the filter cake.

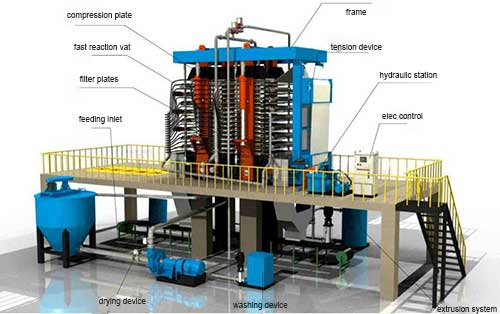

Vertical Filter Press

The filter plates of vertical filter press are superposed both horizontally and up and down to form a group of filter chambers, which occupies a small area. It adopts a continuous filter belt, after the completion of filtering, it moves the filter belt and unloads the filter cake and cleans the filter belt. The operation is automatic.

Vertical filter press has a wide range of applications and simple structure. Compression and opening of filter plate and frame, filter cake discharge and filter cloths cleaning can be operated automatically, which is conducive to the large-scale use of filter press. After the elastic rubber diaphragm is added to the filter chamber of the filter press, the filter cake can be compressed with high pressure water or compressed air at the end of the filter, and the filter cake can be further compressed and dewatered.

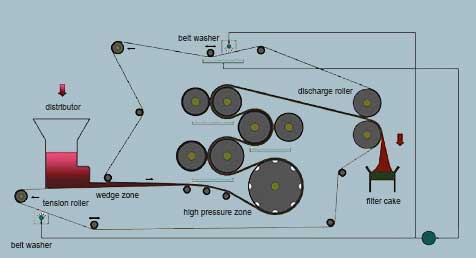

Belt Filter Press

Belt filter press is widely used for sludge dewatering in municipal sewage treatment, electroplating, papermaking, leather, brewing, food processing, coal washing, petrochemical, chemical, metallurgical, pharmaceutical, ceramic and other industries.

Belt filter press has 3 working zones, i.e. gravity dewatering zone, wedge compression dewatering zone and shear dewatering zone. Its compression type belongs to two-dimensional compression and is an ideal equipment for sludge dewatering. However, the dewatering effect of belt filter press depends on chemical agents, which results in high cost of sludge treatment.

Membrane Filter Press

Membrane filter press is an intermittent filter press equipment, which is used for solid-liquid separation of various slurry. The membrane filter press equiped with a layer of elastic membrane between filter plate and filter cloth.

In the process of working, when the feeding is finished, the high-pressure fluid or gas medium can be injected into the membrane plates, at this time, the whole membrane will drum up to compress the filter cake, thus realizing further dehydration of filter cake. Membrane filter presses achieve the lower residual moisture values in the filter cake than traditional filtration processes.

5 Types of Filter Press Comparison

Filter Press has a long history, mainly as a solid-liquid separation equipment, has been widely used, especially in the coal industry. According to statistics, at least 60% of coal manufacturers choose filter press.

With the continuous changes of the market, the demands are becoming higher and higher for filter presses, especially in energy saving and environmental protection, so catering to the complex market demands is an important direction for the development of filter presses.

Learn More About Filter Press (45 Filter Press Terminology)

Learn More About Filter Press (45 Filter Press Terminology) How Many Types of Filter Plates?

How Many Types of Filter Plates? 10 Common Types Filter Press Prices

10 Common Types Filter Press Prices Filter Press Breakdowns And How To Repair

Filter Press Breakdowns And How To Repair

copper concentrate filtreration

Good day,

I am writing to you from Sofcon Group s.r.o, please submit Quotation as per requisition and specs for items mentioned below.

Please note that we accept Incoterm FCA.

Filter press model – SIEMENS 630P32-15-4DYHB (serial F008741)

Position 1 – Press filter paper for Siemens J press brand (serial number F008741) equipment 128cm:66.5 cm thickness 1 mm (Product: 1001505, Material-Polypropylene, Yarns- non-woven, Average Air Permeability (cfm/ft^2 @ 0.5″wg)-3 – 7, *available at multiple air permeability ranges, Finish Glazed 2 sides – 4000 pcs.;

Position 2 – Press tag NO FL501 F008741 Filter cloth 630 FPR.E.PON 1505 GL2 Back int part no 3045 – 30 pcs.;

Position 3 – Press tag NO FL501 F008741 Filter cloth 630 FPR.E.PON 1505 GL2 Back end part no 3046 – 2 pcs.;

Best Regards,

Rashad Mammadov

ok, Mr Rashad Mammadov,

Thanks for you inquiry our filter press machine, we will reply you.

My name is Stefanos Tzeletas and i study chemical engineering. I would like to ask you which is an average effiency of a membrane filter press and which is the remaining moisture after the separation.