Eddy Current Separator & Types | Versus Electrostatic Separation

What Is Eddy Current Separator

Eddy current separator, also known as non-ferrous metal separator, is a sorting equipment mainly applied to the separation of non-ferrous metals such as copper, aluminum, zinc, tin, gold, silver, etc. The effective diameter of the material can be more than 2mm flakes or lumps of non-ferrous metals.

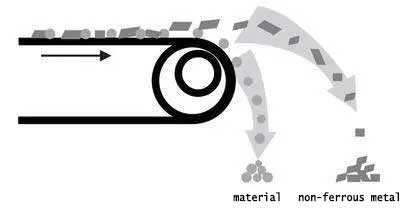

Eddy current separator has a magnet rotor composed of magnets, the rotor in the accelerated rotation will produce alternating changes in the magnetic field, when the metal with electrical conductivity through the magnetic field, will be induced in the metal of the eddy current. This eddy current itself will produce a replacement of the changing magnetic field and with the magnetic field generated by the magnet rotor rolling opposite, non-ferrous metals (copper, aluminum, zinc, tin) will be due to the repulsive effect of the direction of transport jumped out of the direction, so as to achieve the intention of separationg.

Eddy Current Separator Types

Eddy current separator is applicable to a wide range of materials different materials after the sorting effect is different. According to the different magnetic rollers of the eddy current separator, the industry is mainly divided into concentric eddy current separator, eccentric eddy current sorter, eddy current metal sorter.

Eddy Current Separator Applications

1. Concentric Eddy Current Separator

Concentric eddy current separator is the use of high magnetic roller surface to generate high-frequency exchange of strong magnetic field, when the material from the hopper through the strong magnetic sorting area will be induced in the metal block inside the eddy current, so as to sort out the non-ferrous metals, such as copper, aluminum and so on. It can be used in combination with iron remover and vibrating feeding bin.

2. Eccentric Eddy Current Separator

Eccentric eddy current separator is on the basis of eddy current separator, in the non-conducting electromagnetic roller inside the configuration of an eccentric magnetic roller. This equipment is capable of sorting materials that cannot be sorted by concentric eddy current sorters, such as materials with a diameter of less than 2mm.

3. Non-Ferrous Eddy Current Separator

This is a non-ferrous metal material separator equipment, also known as the eddy current metal separator, in the eddy current separatore on the basis of the increase in the drive of the drum can ensure that the equipment is efficient and smooth and long working hours, through the formation of a high magnetic field strength of the eddy currents can be evenly spread over the entire surface of the drum, the magnetic field range is larger, you can sort out the area of the material is more, the sorting effect is more obvious.

In addition, there are permanent magnet eddy current separator, chute eddy current separator and other types, each of which has a unique working principle and application scenarios. The specific choice of which type of eddy current separator needs to be determined according to the actual material characteristics, processing capacity and sorting accuracy and other requirements.

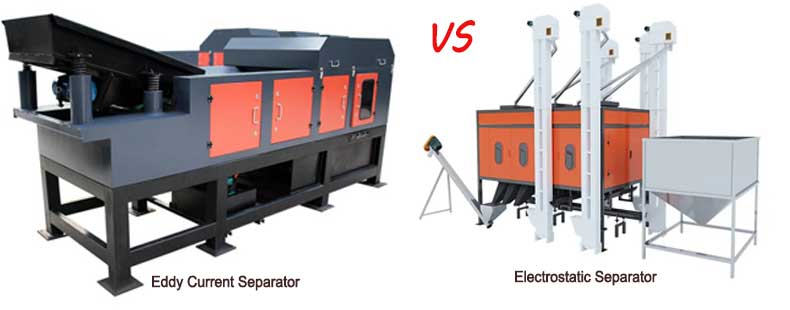

Eddy Current Separator VS Electrostatic Separator

Eddy current separator differ from electrostatic separator in a number of ways.

Material Size

Eddy current separator are primarily designed to sort materials larger than 5mm in diameter, while electrostatic separators are suitable for materials smaller than 1mm. Electrostatic separators are used for materials that are difficult to process with eddy current separator and can separate conductive materials from non-conductive materials from 45 microns to 4mm.

Working Principle

The eddy current separator utilizes the eddy current effect of metals for sorting. When the material passes through the magnetic field generated by the high-speed rotating magnetic rollers inside the eddy current sorter, a magnetic field opposite to the original magnetic field will be generated inside the metal, which will be thrown out by the magnetic field, realizing the separation of metal and non-metal.

Electrostatic separator, on the other hand, is to make the material take on the electrode through high-voltage static electricity, and use the principle of repulsion between the electrode of the magnetic roller and the electrode on the metal surface to separate non-ferrous metals such as copper, aluminum and other non-ferrous metals from non-metals.

Structure

Eddy current separator mainly includes magnetic rollers, driving rollers, material conveyor belt, frame and cover. The magnetic roll is the source of the alternating magnetic field and consists of rare earth permanent magnets, magnetic conductors, gearbox outer cylinders and gearbox system. The speed of the belt and the magnetic rollers can be adjusted by electrical control components for precise sorting of various materials.

The electrostatic separator is mainly composed of electrostatic generator, electric field pole plate, material conveying device, collection device and so on.

Separating Effectiveness

Electrostatic separator has low separating effectiveness, while eddy current separator has high separating effectiveness. Usually, electrostatic separator is when the amount of material is small and fine, while eddy current sorting can be used when the diameter of material is large and the amount is large.

Power Consumption

Because electrostatic induction separating is based on electrostatic sensing for separating, its power consumption is much higher than that of eddy current separator.

Hot 20 Types Mineral Separation Machine [Principle GIF]

Hot 20 Types Mineral Separation Machine [Principle GIF] What is Permanent Magnetic Drum Separator | How Does It Work

What is Permanent Magnetic Drum Separator | How Does It Work How To Classify Magnetic Separators

How To Classify Magnetic Separators Magnetic Minerals | How To Classify Magnetic Minerals

Magnetic Minerals | How To Classify Magnetic Minerals

Looking for separate machine for 0-5mm sand and magnesium metal

Thanks for your inquiry, we will contact you for your demand