12 Types of Sand and Their Uses for Construction

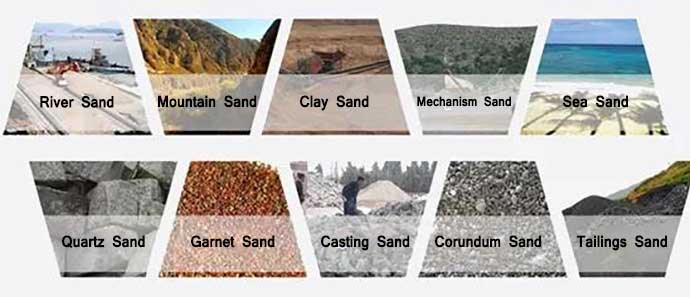

There are various types of sand, and their sources, characteristics, and application scenarios are different. The following are 12 common types of sand and their uses:

1. River Sand

River sand refers to building materials with certain quality standards formed by the natural forces of natural stones in river water, as well as the impact and erosion of river water. Commonly used in the preparation of concrete. The formation process of river sand is very long, and its quality is also influenced by natural environment and human factors.

The particle size, hardness, and mud content of river sand are important parameters for evaluating its quality. In the fields of construction and concrete, river sand is widely used as aggregate and fine aggregate, which can enhance the compressive strength and flexural strength of concrete.

In addition, river sand can also be used to manufacture building materials such as glass and ceramics. Due to the abundant resources and relatively low prices of river sand, it has been widely used in many fields. However, with the increasing awareness of environmental protection, the extraction and processing of river sand also need to pay attention to environmental protection and sustainable development.

2. Sea Sand

Sea sand is sand produced in the ocean (including beach sand, seabed sand) and near the mouth of the sea. Sea sand is influenced by seawater, and untreated sea sand has a high salt content, making it sticky to the touch when held by hand. From the color perspective, sea sand is relatively dark and dark, appearing as a dark brown color. The particle size of sea sand is relatively large, usually measured in centimeters. It is purely natural and is formed by seawater erosion, rolling, collision, and polishing. Sea sand not only contains silica, but also small amounts of minerals such as chloride ions, feldspar, calcium, magnesium, and mica.

Sea sand, as the second largest marine mineral after oil and gas, has many uses. One of the main uses is as a raw material for engineering construction, especially in the land reclamation process of large-scale construction. However, due to the salt chloride ions in sea sand eroding steel bars and posing safety hazards to the project, the sea sand used in the project needs to be desalinated to reduce its salt and chloride ion content.

Sea sand can also be used to manufacture building materials such as glass and ceramics, as well as to extract metallic magnesium. In the field of construction, the application of sea sand is also limited due to its high salt content, which may cause problems with concrete quality and steel corrosion. Therefore, it is necessary to test and control the quality of sea sand when using it.

3. Quartz Sand

Quartz sand originates from quartz deposits, with low mud content and uniform particle size distribution. The main component of quartz sand is silicon dioxide (SiO2). The color of quartz sand is milky white or colorless and semi transparent, with a Mohs hardness of 7. It is brittle and has no cleavage. It has a shell like fracture surface, a greasy luster, a density of 2.65, a bulk density (1.6-1.8 for 1-20 mesh), and a density of 1.5 for 20-200 mesh. Its chemical, thermal, and mechanical properties exhibit significant anisotropy, are insoluble in acids, slightly soluble in KOH solutions, and have a melting point of 1750 ℃.

The characteristic of quartz sand is its high silicon content (usually over 90% silicon dioxide content), which has important applications in industries such as glass, casting ceramics, refractory materials, smelting, ferrosilicon, metallurgy, construction, and chemical engineering. Some quartz sand with high silica content can be used to extract and make silicon wafers, which are one of the key raw materials for manufacturing chips.

4. Mountain Sand

Mountain sand is a type of sand particles formed after weathering of rocks, with a complex composition and high content of organic impurities such as soil. Before collection, it may be necessary to undergo processes such as rinsing. The mud, iron oxide, and organic matter content of mountain sand are relatively high.

The particles of mountain sand often have sharp edges, rough surfaces, and good adhesion with cement. The concrete mixed with it has higher strength.

5. Desert Sand

Desert sand is sand from desert areas, mainly formed by the action of wind. Its characteristics are fine particle size, mostly circular or elliptical in shape, high mud content, and high salt and mineral content. Due to the dry climate and natural conditions in desert areas, desert sand has a higher density, porosity, and good insulation and sound insulation properties. Desert sand belongs to ultra fine sand

In the field of construction, desert sand can be used to manufacture building materials such as concrete and mortar, but its use is limited because its particle size is too fine, its specific surface area is large, it is easy to absorb moisture, and it contains more harmful impurities. Meanwhile, the extraction and transportation costs of desert sand are also relatively high. In some desert countries, desert sand is widely used in road construction, flood control embankments, irrigation channels, and other projects.

6. Clay Sand

Clay sand is a natural sand with a high mud content, mainly composed of clay and fine sand. Its characteristics are high viscosity, strong plasticity, and easy deformation in humid conditions. Clay sand has a finer particle size, a smoother surface, and good fluidity.

Clay sand is mainly used as molding sand and core sand in the casting industry, which can improve the wet strength and molding performance of castings. In casting production, clay sand is usually made by mixing sand, clay, water, and additional materials in a certain proportion. The strength and fire resistance of clay sand depend on the properties of the clay and raw yarn materials, as well as the ratio of sand, soil, and water, and are also affected by factors such as mixing process, compactness, and temperature.

Clay sand can also be used to make building materials such as ceramics and bricks. In the field of construction, clay sand can be used for foundation treatment, pile foundation filling, roadbed cushion layer, etc., playing a stabilizing and protective role. However, due to the high mud content of clay sand, its quality and stability are easily affected. Therefore, suitable clay sand needs to be selected according to specific situations in different application scenarios.

7. Mechanism Sand

Mechanized sand is obtained by crushing rocks with a crusher, and its particle shapes are diverse with distinct edges and corners. Due to the irregular particle shape of mechanism sand and its larger surface area compared to river sand, it has special applications in some special engineering and construction projects. For example, mechanism sand is often used to manufacture high-strength concrete and can also be used to lay road surfaces, improving their skid resistance.

8. Tailings Sand

Tailings sand is made from solid waste such as steel slag, quicklime, and coal gangue. If the process is reasonable, the appearance of the finished product is not significantly different from that of ordinary machine sand, otherwise the particle size may be irregular and incomplete.

Tailings sand can be used to produce cement clinker, develop wall soundproofing materials, develop glazed tiles, manufacture cement, and can also be used as a supplement for filling green belts.

9. Casting Sand

Casting sand is a molding material used in casting production to prepare molding sand and core sand, mainly composed of quartz sand, rock and mineral sand, talc powder, bentonite and other materials mixed in a certain proportion.

Casting sand has good fluidity, compactness, and is easy to demold, making it an essential and important material in casting. Casting sand can play various roles such as support, heat conduction, cooling, and auxiliary bonding through different treatment methods.

10. Colored Sand

Natural colored sand is a natural colored mineral product made by more than ten complex and delicate processes, including raw stone mining, sorting, crushing, mixing, crushing, powder selection, material classification, dust removal, particle size adjustment, color adjustment, packaging, etc.

Natural sand color sand is resistant to high temperature, low temperature, strong acid and alkali, strong corrosion resistance, and long-lasting color. It is mainly used in industries such as imitation stone bricks, permeable bricks, and colored sand beauty agents.

11. Corundum Sand

Corundum sand is a fine abrasive material that has been finely processed, with strong hardness, strong impact resistance, good wear resistance, and strong acid and alkali resistance. It is an ideal abrasive material.

Corundum sand has a wide range of applications, including metal surface treatment, glass polishing, wood polishing, stone polishing, automotive surface polishing, and ship surface polishing. It can also be used for car body polishing, car paint repair, wood polishing, car polishing, car glass polishing, etc.

12. Garnet Sand

Garnet sand is made by grinding garnet as the raw material. Garnet sand has high hardness, high temperature resistance, stable chemical properties, uniform particles, high grinding efficiency, and no scratches.

Garnet sand is often used for sandblasting and rust removal of steel structures to improve their corrosion resistance and appearance quality. It can also be used as a grinding or polishing material for water jet cutting. Garnet sand can be used as a filtering medium to manufacture materials such as ceramics, glass, and coatings.

Why Desert Sand Cannot be Used As Building Materials

Why Desert Sand Cannot be Used As Building Materials 5 Differences Between Sea Sand and River Sand

5 Differences Between Sea Sand and River Sand Recycled Aggregate From Construction Waste

Recycled Aggregate From Construction Waste What is Foundry Sand | How To Choose Foundry Sand in Sand Casting

What is Foundry Sand | How To Choose Foundry Sand in Sand Casting

I apologise, but you could not paint little bit more in detail.