10 Most Valuable Types of Iron Ore and Their Uses

There are various types of iron containing minerals, with over 300 types of iron minerals and iron containing minerals discovered so far, of which more than 170 are common. However, under current technological conditions, the main industrial utilization values include magnetite, hematite, magnetite hematite, ilmenite, limonite, and siderite, etc.

1. Magnetite

Magnetite is a type of iron oxide ore, mainly composed of Fe3O4, with an iron content of about 72.4%. It has ferrous magnetism and is usually attracted by magnets and can be magnetized. It is the most magnetic of all natural minerals on Earth. A naturally magnetized magnetite block is called a magnet.

Magnetite is black or brownish black in color, with a metallic luster and a Mohs hardness of 5-6, leaving black stripes. Its crystals are often octahedral, with a few being rhombic dodecahedra. On the rhombic dodecahedral surface, stripes often appear along the long diagonal direction. Aggregates often appear in dense block and granular shapes. Poor reducibility, generally containing harmful impurities such as sulfur and phosphorus.

Magnetic separation method can be used during mineral processing, which is very convenient for processing; However, due to its fine structure, its reducibility is poor. After long-term weathering, it becomes hematite.

Uses: Magnetite is the main mineral raw material for ironmaking, and many magnetites are also accompanied by elements such as titanium, vanadium, and chromium. It can be comprehensively utilized during the smelting process, and magnetism has important applications in modern medicine, such as nuclear magnetic resonance imaging technology.

2. Hematite

Hematite is a hexagonal oxide mineral with a chemical composition of Fe2O3. Magnetic hematite with equiaxed crystal system( γ- Fe2O3 forms a homogeneous polymorph. Single crystals often exhibit rhombic and plate-like shapes, with diverse aggregate forms such as flakes and scales. The color is reddish brown, steel gray to iron black, and the stripes are all cherry red. Metallic to semi metallic luster.

Uses: Hematite is a widely distributed iron mineral in nature, which is an important raw material for ironmaking and can also be used as a red pigment.

3. Maghemite

Maghemite has been found to be a very common mineral on the surface, often associated with magnetite, and is a good indicator mineral for oxidizing, permeable, and ventilated environments. The chemical formula of magnetite hematite is γ- Fe2O3 often contains a mixture of Mg, Ti, and Mn in its chemical composition.

Maghemite belongs to the equiaxed crystal system, pentagonal tetrahedral crystal class, mostly in the form of granular aggregates, dense blocks, and often exhibiting the illusion of magnetite. The color and stripes are both brown, with a hardness of 5 and a specific gravity of 4.88. It is highly magnetic.

Uses: Maghemite is an important magnetic material for manufacturing music and video tapes, with a wide range of industrial applications. Its biggest feature is strong magnetic force, which can transform hematite or magnetite into magnetite through artificial synthesis.

4. Limonite

Limonite is not actually a separate mineral, but a trioxide iron containing crystalline water. It is a collective term for two different structured ores, goethite and phosphorite. Due to the weathering of other iron ores, brown iron ore has a relatively soft structure, low specific gravity, and high water content. Limonite has different colors due to its different crystal content, ranging from yellow brown to dark brown or black gray.

Uses: The crystalline water of limonite is easily removed during drying, and there are many pores in limonite, making it easy to reduce; Although its iron content is lower than that of magnetite and hematite, it is also an important iron ore due to its looseness and ease of smelting,

5. Ilmenite

Ilmenite is an oxide mineral of iron and titanium, also known as titanium magnetite, and is the main ore for extracting titanium. Ilmenite is heavy, gray to black, with a slight metallic luster. Crystals are generally plate-like, and when they gather together, they form block or granular shapes. The component is FeTiO3. TiO2 content is 52.66%, which is the main mineral for extracting titanium and titanium dioxide.

Uses: Ilmenite is one of the main titanium containing minerals. Since the 1950s, titanium has become a prominent rare metal. Titanium and its alloys were first used in the manufacturing of aircraft, rockets, missiles, ships, etc., and began to be promoted for use in the chemical and petroleum sectors.

6. Siderite

Siderite is a widely distributed mineral composed of ferrous carbonate. When there are not many impurities in siderite, it can be used as iron ore to extract iron. Siderite is generally in crystalline granular or dense massive, spherical or gel shape without crystal. The color is generally gray white or yellow white, which can turn brown or brown black after weathering.

Uses: In addition to being used as a raw material for magnetic materials, siderite can also be used to manufacture products such as ferroalloys, pig iron, wrought iron, and pure iron. The low hardness and brittle texture of siderite make it difficult to cut and polish, making it an extremely rare gemstone variety.

7. Manganese iron ore

Manganese iron ore is a manganese iron oxide mineral, mainly containing iron and manganese elements, and is one of the raw materials for ironmaking. It belongs to the magnetite series in the spinel family, with a gray, granular structure and block like structure. The main mineral composition is quartz, hard manganese ore, and hematite.

Uses: Manganese content in the steel industry accounts for 90% to 95%, mainly used as a deoxidizer and desulfurizer in ironmaking and steelmaking processes. Manganese iron ore, as a raw material for manganese alloys, can improve the hardness, wear resistance, and corrosion resistance of steel, as well as enhance its plasticity and toughness, and improve its mechanical properties.

8. Pyrite

Pyrite is a type of complex sulfide mineral, mainly composed of FeS2, with a light brass color. The surface often has a yellow brown color, metallic luster, and a hardness of 6-6.5. It is a common metal mineral in nature and the most widely distributed sulfide in the earth’s crust.

Uses: Pyrite is formed in various geological processes and can occur in various rocks and ores (including coal seams), with ornamental value. In industry, it is used for extracting sulfur and manufacturing sulfuric acid, and can also be used to manufacture other chemical products such as fertilizers, pesticides, explosives, etc.

9. Chromite

Chromite is a mineral produced by magmatic activity, often occurring in ultrabasic rocks and coexisting with olivine. Chromite looks very similar to magnetite on the surface, usually in the form of block or granular aggregates. Chromite is a scarce mineral with limited reserves and low production. In industry, similar minerals such as chromium iron, chromium spinel, chromium rich spinel, hard chromium spinel, etc. are often collectively referred to as chromite.

Uses: In the metallurgical industry, chromite is mainly used to produce ferrochrome alloys and metallic chromium. Chromium iron alloy is used as an additive in the production of various high-strength, corrosion-resistant, wear-resistant, high-temperature resistant, and oxidation resistant special steels.

10. Goethite

Goethite is an iron containing oxide mineral with the chemical formula FeO (OH). It is usually black or brown and has magnetism. Goethite is widely distributed in nature and can form in sedimentary, volcanic, and metamorphic rocks, as well as in soil.

Uses: Goethite is also widely used in industry, such as as as a pigment, catalyst, and magnetic material. Goethite is also an important type of iron ore, which can be used as a raw material for extracting iron.

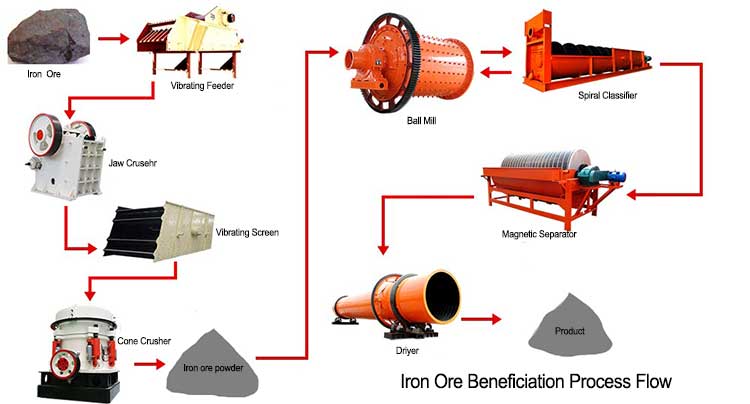

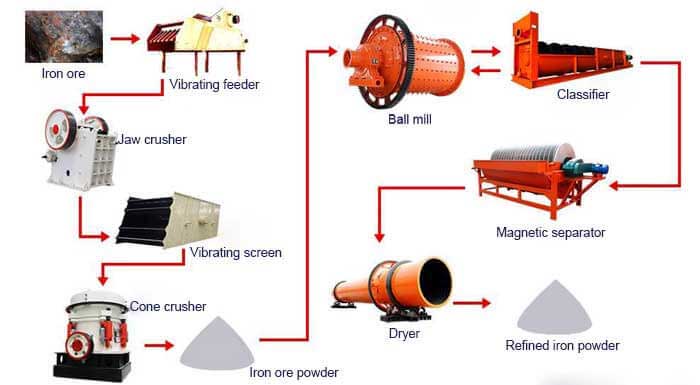

Iron Ore Beneficiation Process Flow

The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation), mineral dewatering(concentration, filtration, dewatering, drying, etc.). The ultimate goal of mineral processing is mainly to dissociate minerals from gangue.

- ① Crushing: Firstly, large pieces of iron ore are fed into a jaw crusher for preliminary crushing by a feeder. Then, the crushed iron ore is conveyed through a belt conveyor to a cone crusher for further crushing until the required product particle size and specifications are achieved.

- ② Grinding: The crushed iron ore enters the ball mill for grinding, and the fineness of the ground iron ore can reach 0-325 mesh, meeting the subsequent selection needs.

- ③ Beneficiating: The ground iron ore enters the magnetic separator for magnetic separation, which can remove most non-magnetic impurities such as gangue. The iron concentrate powder after magnetic separation is carefully selected to ensure product quality.

The iron ore beneficiation process may also include other beneficiation methods such as gravity separation and flotation, depending on the type of iron ore and the quality level of iron concentrate powder to be produced.

The specific beneficiation process of iron ore may vary depending on factors such as region, ore type, beneficiation plant scale, and technical level. For example, the beneficiation process of magnetite quartzite may include multiple stages such as magnetic separation and flotation, while weak magnetic iron ore may require the use of various combination processes such as weak strong magnetic separation and flotation.

Magnetic Minerals | How To Classify Magnetic Minerals

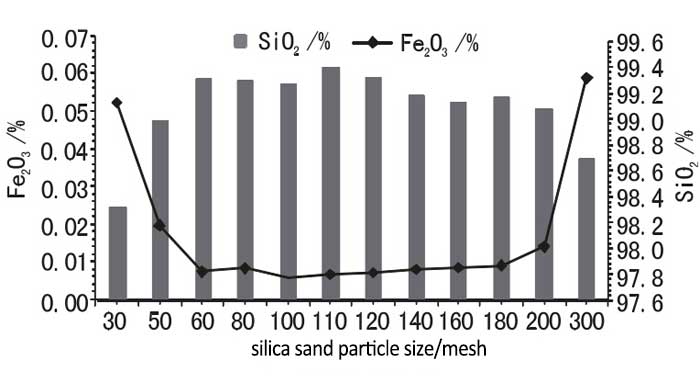

Magnetic Minerals | How To Classify Magnetic Minerals 8 Methods for Removing Iron From Silica Sand

8 Methods for Removing Iron From Silica Sand What is Granite [Composition, Properties, Types, Uses]

What is Granite [Composition, Properties, Types, Uses] Silica Sand Washing Plant | Quartz Sand Processing

Silica Sand Washing Plant | Quartz Sand Processing