Sludge, Sludge Dewatering, Why & How To Dewater Sludge

What Is Sludge

Sludge is the sediment, particle and floating object produced in the treatment of wastewater by physical, chemical, physical-chemical and biological methods. Sludge generally refers to the semi-solid slurry between liquid and solid, which can be transported by slurry pump, but it is difficult to separate solid and liquid through sedimentation.

5 Types of Sludge On Basis of Treatment Methods

- 1. Sludge from Primary Sedimentation Tank

- 2. Activated Sludge

- 3. Humic Sludge

- 4. Chemical Sludge:

- 5. Primary Settlingsludge

What is Sludge dewatering

Sludge dewatering is a kind of sludge treatment method which can remove water from the primary, thicked or digested sludge and convert it into semi-solid or solid sludge. After dewatering, the moisture content of sludge can be reduced to 55-80%.

Why is Sludge Dewatering

After the sludge is thickened and digested, the water content is still has about 95% – 97%. For comprehensive utilization and final disposal, sludge needs to be dewatered.

The purpose of dewatering is to remove the water existing between and within the sludge particles, so as to change the physical properties of the liquid sludge into semi-solid, so as to keep the disposal cost ( including transportation) at the lowest.

In general, sludge drying after dewatered by sludge dewatering machines can save about 60% of energy. Take sludge with initial moisture content of 80% and final moisture content of 25% as an example:

Drying directly without sludge dewatering requires 479520 cal energy; but, after dewatering, the moisture can be reduced to 60% and then dried in the dryer, which only requires 159750 cal energy.

The ideal sludge dewatering should be to remove the water to the maximum extent, while the solid particles of sludge should be all kept on the dewatered sludge cake, and the minimum investment should be required for this operation.

5 Types of Sludge Dewatering Methods

Sludge dewatering helps to reduce the weight and volume of sludge before transportation and management. Sludge dewatering can greatly reduce the cost of the 2 processes.

Common sludge dewatering technologies include:

- Plate and Frame Filter Press Dewatering

- Belt Filter Press Sludge Dewatering

- Centrifuge Sludge Dewatering

- Stacked Sludge Dewatering

- Screw Press Sludge Dewatering

1. Plate and Frame Filter Press

Working Principle: in the closed state, the sludge pumped by the high-pressure pump is squeezed by the plate and frame, so that the water in the sludge is discharged through the filter cloth, so as to achieve the purpose of dehydration.

- Advantages: low price, good at dehydration of inorganic sludge, low moisture content of sludge cake.

- Disadvantage: easy to block, high pressure pump is required, not suitable for dehydration of oily sludge.

2. Belt Filter Press

Working Principle: the sludge is carried by two tensioned filter belts. From a series of regularly arranged roller, it passes in the shape of S. depending on the tension of the filter belt itself, the squeezing and shearing force on the sludge layer is formed, and the capillary water in the sludge layer is squeezed out, so as to realize the sludge dehydration.

- Advantages: low price, universal use, relatively mature technology.

- Disadvantages: easy to block, need a lot of water cleaning.

3. Centrifuge

Working Principle: Centrifuge is composed of a transfer and a screw conveyor with a hollow shaft. The sludge is sent to the rotary drum through the hollow rotary shaft. Under the centrifugal force generated by high-speed rotation, it is immediately thrown into the drum cavity. Due to different specific gravity, solid-liquid separation is formed. Driven by the screw conveyor, the sludge is continuously discharged from the cone end of the drum by the outlet; the liquid in the liquid ring layer is continuously “overflowed” from the weir mouth to the outside of the drum by gravity.

- Advantages: large processing capacity.

- Disadvantages: high power consumption, loud noise and not suitable for solid-liquid separation with close specific gravity.

4、Stacked Sludge Dewatering Machine

Working Principle: Stacked sludge dewatering machine can fully dewater through gravity concentration and the internal pressure formed by the back pressure plate during the process of sludge propulsion. The filtrate is discharged from the filter joint formed by the fixed ring and the movable ring, and the mud cake is discharged from the end of the dewatering part.

- Advantages: self-cleaning, no blocking, low concentration sludge dewatering, fully automatic control.

- Disadvantages: small treatment capacity, not good at the dehydration of sludge with large particles and hardness.

5. Screw Press Sludge Dewatering Machine

Working Principle: The screw shaft of screw press sludge dewatering machine is installed in the cylinder that composed of filter screens. The diameter of the screw shaft gradually becomes larger from the inlet to the outlet of the dehydrated part. With the volume between the screw blades becoming smaller, the dewatered raw material is also gradually compressed.

The solid and liquid in the dehydrated raw material are separated by compression, and the filtrate is discharged through the mesh of the filter screen.

- Advantages: continuous dehydration, simple structure, low speed, less wearing parts.

- Disadvantages: small processing capacity.

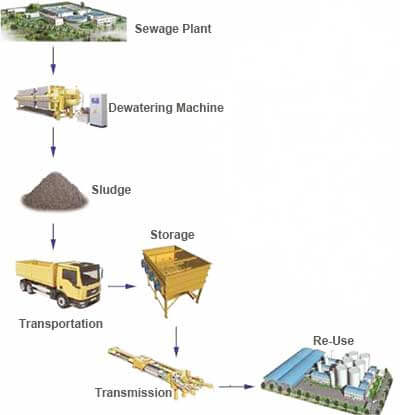

4 Steps for Sludge Treatment Process

- 1. Sludge Thickening: the main purpose is to reduce the initial capacity of sludge and the capacity of subsequent treatment structures or equipment;

- 2. Sludge Digestion: under anaerobic condition, the organic matter in sludge is degraded by bacteria into methane based sludge gas and stable sludge to decompose the organic matter in sludge;

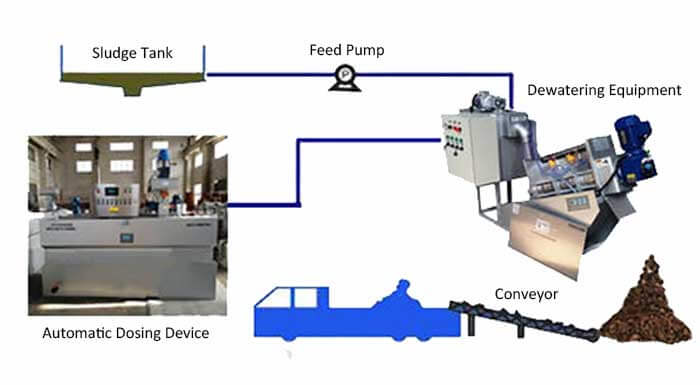

- 3. Sludge Dewatering: use screw filter press, belt filter press or centrifuge to further reduce sludge capacity;

- 4. Sludge Management: Sludge transmission system is composed of receiving bin, screw feeder, plug valve, sludge pump and pipeline. The whole sludge transportation process has no peculiar smell, does not pollute the environment, and can be transported for a long distance and a large lift. Landfill or reuse the final dewatered sludge.

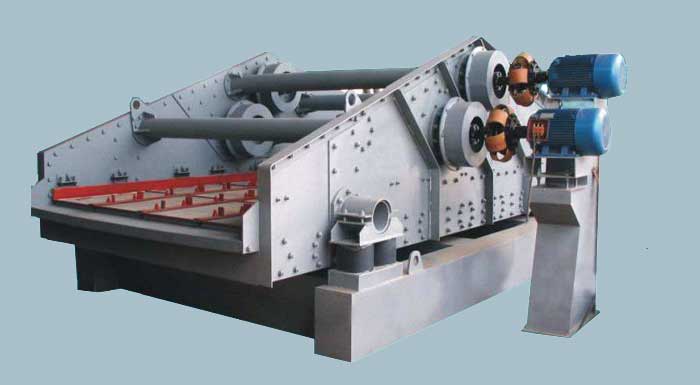

Dewatering Equipments for Mineral & Sludge

Dewatering Equipments for Mineral & Sludge 6 Sludge Treatment Processes and Technologies | Cmparative & Analysis Report

6 Sludge Treatment Processes and Technologies | Cmparative & Analysis Report Dewatering Screens | Why & How To Choose Dewatering Screens

Dewatering Screens | Why & How To Choose Dewatering Screens Coal Dewatering Screen | Working Principle | Features

Coal Dewatering Screen | Working Principle | Features