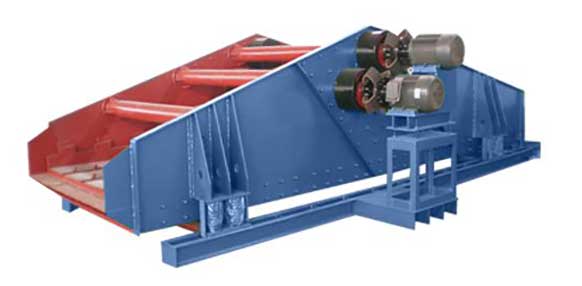

Coal Dewatering Screen | Working Principle | Features

Coal dewatering screen is a kind of screening equipment developed for dewatering, desliming and degritting of slurry materials. It is widely used in coal slime dewatering, pressure filtration separation, dewatering and recovery of very fine materials, etc.

How Coal Dewatering Screen Work

The coal dewatering screen adopts double motor self-synchronization technology, general eccentric block and adjustable amplitude vibration exciter.

Coal dewatering screen is mainly composed of screen box, vibratory exciter, supporting system and motor. When working, the two unrelated actuators are driven by belt couplings to run synchronously and in reverse. The centrifugal forces produced by the two groups of eccentric blocks are superimposed along the vibration direction and counteracted by reverse centrifugation, thus forming a single excited vibration along the vibration direction, which makes the screen box move back and forth in a straight line.

The slime entering the coal dewatering screen changes the surface water tension through the exciting force, and the slurry water passes through the screen to become the material under the screen, while the fine material is blocked by the screen panel to form a filter layer to move forward and discharge under the influence of vibration force.

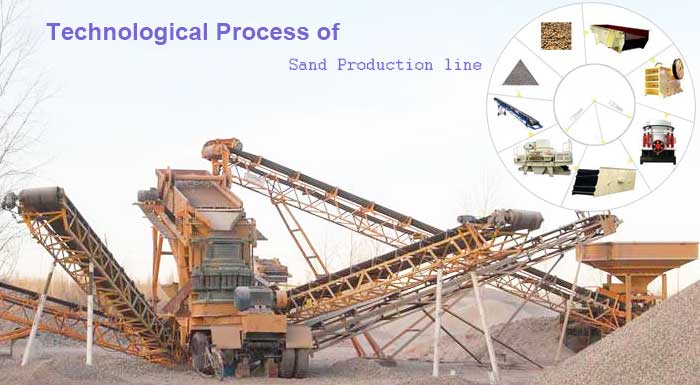

Coal Dewatering Screen Applications

Coal dewatering screen not only has a variety of excellent properties and functions of ordinary dewatering screen, but also cooperates with thickeners for dry discharge of tailings, which is the best equipment for dewatering and dry discharge of tailings at present. Coal dewatering screen is mainly used for dewatering and classification of medium and fine materials, with large processing capacity and high screening efficiency.

Coal Dewatering Screen Features

- 1. Reasonable structure, firmness and durability, low noise and convenient maintenance.

- 2. The slime is dewaterd and recovered thoroughly, and the use effect is good.

- 3. Light weight, convenient disassembly and assembly, easy maintenance and low production cost.

- 4. Small volume and large processing capacity, which is convenient for layout of the coal washing plant.

- 5. The structure of the screen panel is modular design, and it is convenient to replace.

- 6. Compared with the use of complex coal slime filter, filter press and settling filter centrifuge systems, coal dewatering screen saves a lot of investment.

Become More Professional In Dewatering Screen

Become More Professional In Dewatering Screen Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Top 10 Vibrating Screen Types & Working Principle [How To Choose] Coal Preparation Plant | Coal Preparation Process | Coal Washing

Coal Preparation Plant | Coal Preparation Process | Coal Washing Spiral Chute | Working Principle | Features | Specification

Spiral Chute | Working Principle | Features | Specification