Wet Sand Making VS Dry Sand Making

In recent years, with the limitation of natural sand mining and the scarcity of resources, artificial sand has gradually become the mainstream of the market.

But in the process of stone processing, because of the intense collision and the stone itself has a certain amount of soil, the artificial sand contains a certain amount of stone powder and mud powder, thus affecting the gradation of artificial sand.

In order to solve the problem of silt content, wet sand making and dry sand making is developed.

Wet Sand Making & Dry Sand Making

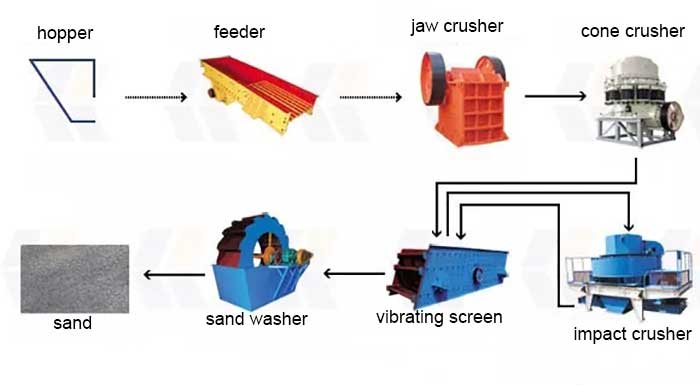

In short, sand washing plant is equiped with sand washers and the stone power will be washed away in the process, this method is called wet sand making. It is more suitable for rainy and water-rich areas.

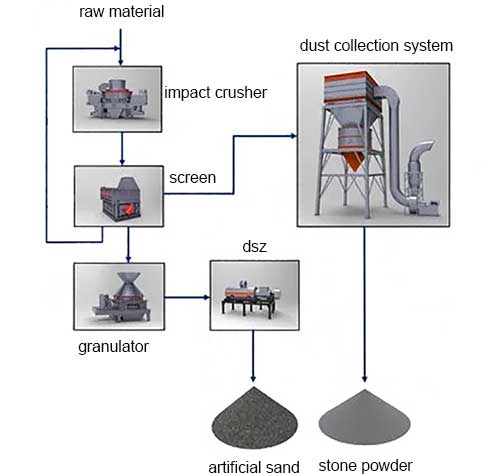

Using flour separator, the method of separating sand and powder is called dry sand making, which is more suitable for water shortage areas, where environmental protection requirements are not very high.

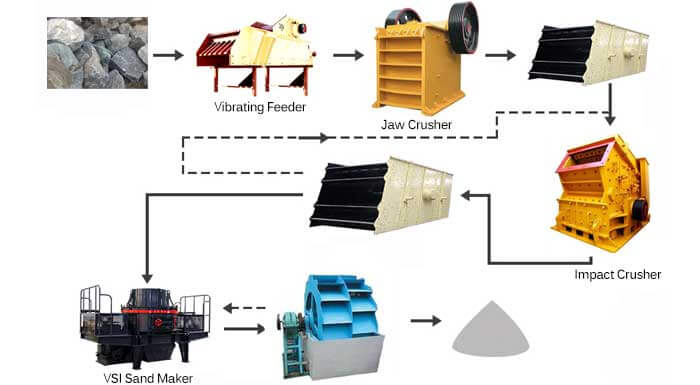

Similarities between the two sand making methods

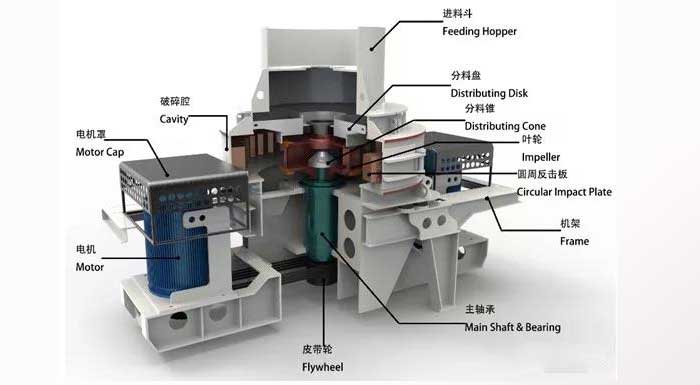

The main equipments used in the two production lines are the same, i.e. the primary crusher, the finer crusher and the efficient sand making machine are the main parts. The purpose of both is the same, both for the sake of higher quality sand and conforming to the standard of building sand.

Differences between the two sand making methods

1. Different Follow-Up Equipment

Wet sand making is a sand making mode using sand washing machine, which can achieve the roundness of sand grains in appearance and reduce the content of soil.

Dry sand preparation is based on the model of flour separator, which achieves the separation of sand and powder, and ultimately selects the construction sand with excellent quality. Dust will also be collected as a bye-product.

2. Different Applicable Areas

The wet sand method is suitable for many water areas, which are close to the water source. The wet sand method can set up sedimentation tank to achieve the purpose of recycling water resources. At the same time, the fine sand recovery machine can be added to collect fine sand and sand powder in wastewater.

Dry sand is suitable for areas far away from water sources, such as arid areas.

3. Different Investment Costs

Dry sand production line uses high efficiency flour separator to separate sand powder. There is no need to increase the amount of water in the production process, and the overall production cost will be relatively low.

4. Different development times

Dry sand making technology is later than wet sand making technology, which is further developed on the basis of traditional wet sand production line. Compared with wet sand production, this technology does not need water in the process of sand powder removal, so it is called dry sand production line.

Comparison of Advantages and Disadvantages:

In actual production, the choice of wet sand making or dry sand making depends on the region and water resources, the cleanliness of raw materials, and the specific requirements of aggregate, artificial sand powder content and fineness modulus. Users should choose according to their own production conditions.

3 Million Granite Sand Making Production Line

3 Million Granite Sand Making Production Line VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications How To Select Sand Making Machine?

How To Select Sand Making Machine? A 800 TPH Sand Making Plant Details

A 800 TPH Sand Making Plant Details

Can you please send us a catalog of both wet sand making machines and dry sand making machines, capacity from 10tph&prices .The raw materials will be from alluvial sand/soils.

Hello Mr Kingstone Chiwaridzo,

Thanks for inquiry sand making machines, we will contact you by the email