5 Steps Help you Choose and Replace Bucket Teeth yourself

Bucket teeth is one of the most easily worn parts in the whole excavator equipment. Its shape is like a human tooth, which is composed of tooth base and the tooth tip, and the tooth tip is the most vulnerable part to failure. The quality of bucket teeth directly affects the working efficiency and production cost of a excavator or a loader.

As a professional excavator or loader driver, sometimes you have no choice but to replace the bucket teeth yourself, so you urgently need to master the skills of choosing and replacing the bucket teeth correctly. In this article, you will learn how to choose right bucket teeh and replace the worn bucket teeth yourself by following simple steps.

5 Steps Help you Replace The Old Bucket Teeth yourself [PDF Download]

1. Identify your Bucket Teeth Types

According to different applications, the common bucket teeth on the market are divided into three types:

- 1. Chisel Tooth: Chisel tooth is a kind of bucket tooth which is used to excavate soil, sand and gravel in sand and soil terrain. Generally, the chisel teeth are matched with the bucket with a large bucket mouth area, which has a large stacking surface, so it has a high filling coefficient and saves operation time.

- 2. Rock Tooth: Rock tooth is usually suitable for the digging of iron ore, stone and other environments. It is made of heavy working strength wear-resistant steel, with better digging performance and outstanding economic effect.

- 3. Tiger Tooth: Tiger tooth is mainly used for penetrating rock stratum with low hardness. Tiger teeth have great impact force and are widely used in coal mining.

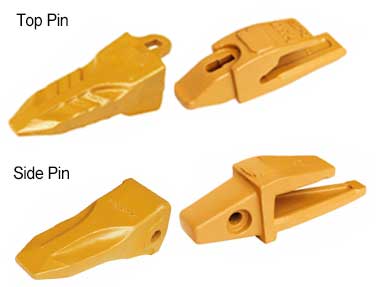

2. Identify your Bucket Tooth Installation Style

Common installation include side pin installation style and top pin installation style.

Top Pin: Top pin style refers to the vertical installation of the pin and digger bucket tooth, with large operation space and convenient disassembly, and the pin is smashed directly from above.

When digging, the top pins will be subjected to the front extrusion pressure of materials, and if the digging force is large and the retainer can not meet the requirements, it is easy to cause the tooth pin to fall off, so this style is generally used in the digging machine with lower tonnage.

Side Pin: Side pin style refers to the horizontal installation of the pin. The side operation space is small and it is not very convenient to disassemble, so special long rod tools must be used in order to disassemble and assemble.

When digging, side style pin can bear more excavating force, which is generally used in more than 20 tons of excavators. However, if the retainer is subjected to a large reciprocating lateral force in use, it is easy to wear and fail, resulting in the tooth pin falling off.

3. Identify your Bucket Teeth Quality

Bucket teeth quality is greatly affected by the diffenent processing methods, Common product tech include: forging cast, precision cast and sand cast.

Forged Teeth: forged teeth are the highest cost and the best quality of bucket teeth.

Key Tips: If the excavator is used for earthwork projects, the frequency and demand of replacing bucket teeth are smaller, so it is recommended to select forged bucket teeth. Although the teeth price is much higher, the service life, manufacturing process and quality are all the best.

Precision Cast Teeth: cast teeth price is moderate, but the requirements for raw materials are very strict, and the technological level is relatively higher. The wear resistance and quality of some precision cast teeth are even higher than those of forged teeth due to ingredient.

At present, precision cast teeth is the mainstream manufacturing technology in the market.

Key Tips: If there is a great demand for bucket teeth, precision casting bucket teeth are an ideal choice, because precision casting bucket teeth have advantages in terms of price, quality, performance-to-price ratio and wear resistance.

Sand Cast Teeth: sand casting bucket teeth price is the lowest, and the technological level and quality of sand casting bucket teeth are not as good as those of precision cast teeth and forged teeth.

4. Indentify your Bucket Teeth Size

You can buy bucket teeth that matching the excavator sizes or just choose general-purpose teeth.

If you do not know the specific model of the excavator, you can determine the bucket teeth size by measuring the pin and retainer sizes, or you can measure the teeth pocket size, it’s also a good method.

5. Replace your Worn Bucket Teeth

The following is a simple bucket teeth replacement guide for excavators or loaders, by which you will learn how to replace the worn bucket teeth all by yourself.

- 1. Adjust the excavator bucket to a right position to ensure safety and stability (prevent the bucket teeth from hitting your legs or feet).

- 2. Use the pin removal tool to remove worn teeth by hammering the keener-pin out from the side with retainer.

- 3. Remove stains from the adapter with a wire brush or other cleaning tool. Replace the adapter if it’s worn.

- 4. Place the new teeth and retainer in the original position of the adapter, insert the pin into the adapter and retainer, and hammer it in with a sledgehammer, making sure the pin is fully inserted.

- 5. Complete the replacement of one tooth, you will be alble to install all the teeth of your loader or excavator sucessfully by repeating the above steps yourself without professional assistance.

Does it need to be more intuitive? Please refer to the video below:

How to improve The Excavator Bucket Teeth Service Life

How to improve The Excavator Bucket Teeth Service Life 20 Types of Excavator Buckets and How To Choose A Suitable Bucket

20 Types of Excavator Buckets and How To Choose A Suitable Bucket Bucket Elevator | Structure & Types| How To Choose

Bucket Elevator | Structure & Types| How To Choose 12 Common Bucket Elevator Troubleshooting

12 Common Bucket Elevator Troubleshooting

I am looking for 4 bucket teath for hitachi ex40 the only marking S8l they look like the ones on page. The top pin

ok sir