20 Types of Excavator Buckets and How To Choose A Suitable Bucket

The bucket is the most important accessory on excavators, with many types, various shapes, and various functions. According to different working conditions, the equipped buckets are also different. Choosing a suitable bucket can greatly improve work efficiency. So how do you choose a satisfactory bucket?

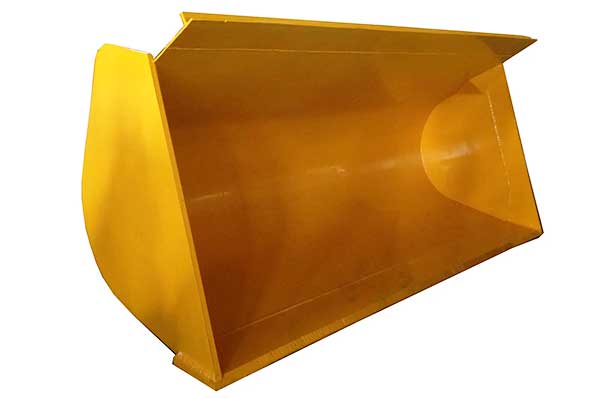

1. Standard Bucket

The standard bucket has a large capacity, a large mouth area, and a large stacking surface. This type of bucket is the most common and suitable for various soil and operating conditions. It has a high filling coefficient, high work efficiency, and low production cost..

Benefits: High universality, strong wear resistance, easy replacement and maintenance.

2. Reinforced Bucket

Strengthening the excavation bucket is a type of excavation bucket that uses high-strength wear-resistant steel materials to reinforce high stress and easily worn parts on the basis of the original standard bucket. It not only inherits all the advantages of the standard bucket, but also greatly improves its strength and wear resistance, greatly extending its service life.

Benefits: Suitable for heavy load operations such as excavating hard soil, soft stones, and loading crushed stones and gravel.

3. Rock Bucket

The rock bucket is designed specifically for heavy duty operations in hard rock and soil mixed with a large amount of stones, with higher strength and wear resistance. Reinforcement is provided on both sides of the bucket teeth, bucket wings, bucket teeth, and the bottom of the excavation bucket. In addition, side shields and protective plates are added to the rock bucket.

Benefits: Stronger bucket teeth, more durable bucket body, and more efficient excavation performance make rock buckets suitable for heavy load operations such as mixing harder stones, sub hard rocks, weathered rocks, and hard rocks in soil.

4. Scarifier Bucket

The loosening bucket is equipped with high-strength loosening teeth, which are generally designed with three or more teeth, giving it strong excavation ability and soil breaking effect. It can complete the crushing, excavation, and loading of hard soil, sub hard rocks, and wind fossils in one go, with high efficiency.

Benefits: Strong excavation power and high efficiency, wide applicability and flexibility, suitable for different sizes and types of excavators, as well as different excavation environments and job requirements

5. Ditch Bucket

A ditch bucket is a specialized excavator accessory used for excavating ditches, channels, and drainage ditches. Its main feature is that it is designed with specific buckets and buckets, which can adapt to excavation operations of channels and drainage ditches of different shapes and sizes.

The ditch bucket is suitable for various types of excavators, whether it is a tracked or wheeled excavator, and can be easily installed and used. Its main applications include infrastructure construction, agricultural water conservancy engineering, underground pipeline laying, mining, etc. Ditch buckets can efficiently excavate ditches, channels, and drainage ditches, improving the construction speed and quality of drainage systems.

Benefits: The ditch bucket can easily handle excavation operations of various shapes and sizes of ditches, channels, and drainage ditches, and can ensure long-term stable service life.

6. Screening Bucket

The screening bucket is a special excavator accessory that combines functions such as excavation, screening, and separation. It can be used for sand and stone separation, pipeline backfilling, river sand and gravel cleaning, soil and rock separation, and construction waste screening.

The size of the sorting and screening treatment can be adjusted by replacing the screening plate (the mesh size ranges from 10mm to 150mm), which can classify and screen mixed garbage, sawdust, construction debris, etc. according to their size.

Benefits: The screening bucket is widely used for screening various materials, whether it is soil and rock mixture, coal slurry, construction waste, or other types of materials, which can be smoothly screened.

7. Multifunctional Bucket

This type of excavator can replace different blades and adapt to different working environments, such as crushing, cutting, excavation, etc.

Benefits: Higher versatility and flexibility.

8. Snow Bucket

The bottom of this snow bucket is designed in the shape of a snow shovel, which can be used to clean snow and loose soil.

Benefits: Suitable for clearing snow and loose soil, high efficiency, etc.

9. Wide Bucket

This type of excavator bucket has a larger width and can be used for large-scale excavation operations to improve excavation efficiency.

Benefits: Higher mining efficiency and quality.

10. Telescopic Bucket

This type of excavator can be retracted to meet the excavation needs of different depths and sizes.

Benefits: including strong adaptability, high mining efficiency, and ease of operation.

11. Tilting Bucket

The tilting bucket can be controlled to rotate through the action of the oil cylinder, with a maximum tilt angle of 45 degrees. It can be operated without changing the position of the excavator, easily completing precise tasks that ordinary buckets cannot complete. Suitable for trimming work such as slope brushing and leveling, as well as dredging work of rivers and ditches.

Benefits: Convenient to clean soil and debris on the side panel, improving work efficiency.

12. Elongated Bucket

The elongated bucket has a longer length and can excavate deeper or wider gullies. The enlarged bucket groove and body can enable the excavator to achieve greater depth and width during excavation operations, improving excavation efficiency and quality.

Benefits: Deeper excavation depth and wider excavation width.

13. Grading Bucket

The grading bucket can adapt to the separation and loading needs of various materials, such as coal, rock, soil, etc., and has a wide range of applications. The grading bucket is a very popular choice when loading and unloading materials, grading, leveling, and backfilling holes.

The shape and size of the grading bucket can be customized according to different excavator models and work requirements to ensure compatibility with the excavator and work efficiency.

Benefits: Grading buckets are a popular choice for precision operations and are highly favored by landscape designers, road construction workers, and construction sites.

14. Trapezoidal Bucket

The trapezoidal bucket is mainly used for excavating and cleaning trapezoidal shaped materials, such as stones, bricks, concrete, etc. It can be used for excavation operations at different angles and positions to improve excavation efficiency. The trapezoidal excavator can also be used to clean trapezoidal shaped debris and garbage.

Benefits:The price of trapezoidal buckets is relatively low, which can reduce the cost of excavation operations. At the same time, the trapezoidal excavator has a long service life and can be used multiple times, reducing the cost of replacement and maintenance.

15. Rake Bucket

The rake bucket is shaped like a nail rake and is generally wide, divided into 5 or 6 teeth. It is mainly used for cleaning in mining engineering, water conservancy engineering, and other areas.

Benefits: Dig out debris such as tree roots and bushes while allowing soil, dirt, and other fine aggregates to pass through.

16. Skeleton Bucket

Skeleton bucket is similar in design to a standard bucket, but its bottom is a sieve mesh and its volume is generally large. Mainly used for excavating materials such as clay and sediment. Its main feature is the design of grid shaped bucket teeth inside the bucket groove, which allows the excavator to easily excavate materials such as clay and sediment during the excavation process, while avoiding material blockage at the bucket mouth.

Benefits: Suitable for separating soft excavation materials, and the excavation and separation can be completed in one go.

17. Shell Bucket

The working principle of a shell bucket is to use the expansion and contraction of the oil cylinder to drive the shell body to open and merge to grab materials, thus completing the operation.

Benefits: Suitable for excavation of foundation pits, deep pits, and unloading and loading of loose materials such as coal and sand in construction bases, especially for excavation or loading operations in restricted spaces.

18. Thumb Bucket

A baffle is installed in front of the excavation bucket to reduce the possibility of material falling or to directly grab the material. Suitable for areas where materials are prone to tipping during excavation and loading, especially for areas with high lifting during loading.

Benefits: It is very convenient for grasping small wood, rod shaped objects, and strip shaped objects.

19. Mud Bucket

Mud bucket, also known as dredging bucket, has no bucket teeth and a large width. It is suitable for surface trimming of slopes with large capacity, as well as dredging work of rivers, ditches, etc.

Benefits: The design of mud bucket teeth is also diverse, including flat bucket teeth, conical bucket teeth, and elongated bucket teeth. These different bucket tooth designs can be applied to different types and hardness of materials.

20. Clean-up Bucket

Excavator cleaning buckets, also known as clean-up buckets or digging buckets, are specially designed for cleaning slopes and other surfaces, as well as large-scale dredging and cleaning work in rivers and ditches, with powerful functions.

It can also be used for loading and unloading ships and train compartments. The cleaning bucket does not have bucket teeth, tooth seats, or bucket corners, and this structure will not cause damage to the bottom plate of the ship and train compartments during operation.

Benefits: The clean-up bucket is designed for specific work needs, and its use can effectively improve the efficiency and cleanliness of related work.

How To Choose an Excavator Bucket?

1. Work Environment

When choosing the specifications of an excavator bucket, the first thing to consider is the working environment. If the working environment is narrow, the terrain is rough, and there are obstacles, it is recommended to choose a lightweight bucket for easy operation and adjustment; If the working environment is open and flat, it is recommended to choose a heavy bucket to improve excavation depth and efficiency.

2. Excavating Materials

Choosing the specifications of the excavator bucket also requires consideration of the properties of the excavated material. If the excavation is on soft soil or sand, it is recommended to choose a lightweight bucket; If excavating hard rock or concrete, it is necessary to choose a heavy bucket.

3. Excavation Depth and Intensity

The weight of the excavator bucket also has a significant impact on the depth and intensity of excavation. It is necessary to select appropriate specifications based on specific work needs to achieve optimal work efficiency.

4. Excavator Model Matching

The specifications of the excavator bucket also need to be matched with the model. When choosing an excavator bucket, it is necessary to understand the technical parameters and working properties of the excavator you are using to ensure that the selected bucket can fully utilize the performance and efficiency of the excavator.

5. Consider Bucket Features

The features of a bucket include tooth shape, number of teeth, capacity, and materials. The number of teeth in the excavation bucket should be selected based on the operating object and environment, such as soft soil suitable for multi tooth buckets and hard rock suitable for few tooth buckets. Conical teeth are suitable for crushing operations, while flat teeth are suitable for excavation operations.

High manganese steel is suitable for wear-resistant and impact resistant working environments, while low-carbon steel is suitable for mild wear working environments. In addition, the service life and maintenance cost of the bucket also need to be considered.

The excavator bucket is one of the important indicators of the excavator’s working ability, and the correct selection of a suitable bucket is the key to improving the excavator’s work efficiency and reducing operating and maintenance costs.

How to improve The Excavator Bucket Teeth Service Life

How to improve The Excavator Bucket Teeth Service Life 5 Steps Help you Choose and Replace Bucket Teeth yourself

5 Steps Help you Choose and Replace Bucket Teeth yourself Excavator Daily Maintenance Schedule

Excavator Daily Maintenance Schedule 8 Tips Help To Choose A Suitable Screw Conveyor

8 Tips Help To Choose A Suitable Screw Conveyor

Hi Dear,

Glad to hear that you’re on the market for excavator bucket, we need excavator accessories, such as standard bucket, rock bucket, screen bucket , rippers,augers and so on. Can you provide products with good quality and competitive price?

Should you have any questions,call me,let’s talk details.

Best regards!