Magnetic Minerals | How To Classify Magnetic Minerals

What is Magnetic Minerals

Some minerals with magnetism are usually called magnetic minerals. The magnetism of mineral refers to the property that mineral is attracted or repelled by permanent magnet or electromagnet. In general, the strength of mineral repulsion by magnetic field is very weak. Therefore, in the identification, separation and general research of minerals, the magnetic properties mainly refer to the properties of minerals attracted by the external magnetic field. The magnetism of minerals mainly depends on whether there are unpaired electrons in the mineral lattice. The more unpaired electrons, the stronger the magnetic performance.

How To Classify Magnetic Minerals

The classification of minerals by magnetism is based on the magnetization coefficient(X). In magnetic separation, the larger the difference of magnetization coefficient is, the easier the separation is. According to the magnetization coefficient of minerals, all minerals can be divided into the following 4 types:

1. Strong Magnetic Mineral

The magnetization coefficient (x) of strong magnetic minerals >3000 *10^(-6)cm³/g. It can be selected from weak magnetic separator with magnetic field strength H = 7200 ~ 136000 A/M, which is easy to process.

Strong magnetic minerals is little. It mainly includes: Magnetite, Magnetite (γ – hematite), Titanomagnetite, Pyrrhotite, Zinc iron spinel, etc. Most of these minerals are ferromagnetic minerals.

2. Medium Magnetic Mineral

The magnetization coefficient (X) of medium magnetic minerals is between (600-3000) *10^(-6)cm³/g.

Only Ilmenite and Pseudo Hematite are medium magnetic minerals. The magnetic separator with magnetic field intensity H of 160000-480000 A/M is needed to select such minerals.

3. Weak Magnetic Mineral

The magnetization coefficient (X) of weak magnetic minerals is between (15-600) *10^(-6)cm³/g. It can be selected from the strong magnetic separator with the magnetic field strength H = 480000 ~ 1600000 A/M.

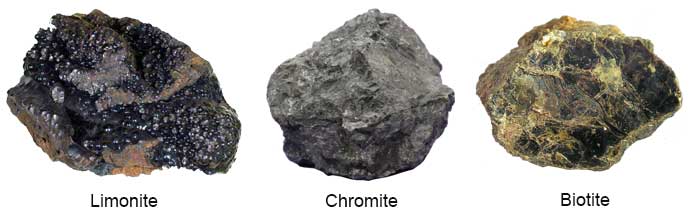

The most weak magnetic minerals are Hematite, Specularite, Limonite, Siderite, Pyrolusite, Pyrolusite and Rhodochrosite; Some minerals containing chromium and tungsten – Chromite, Wolframite, etc; Some rock forming minerals – Biotite, Hornblende, Epidote, Chlorite, Serpentine, Olivine, Tourmaline, Pyroxene, etc.

4. Non-Magnetic Mineral

The magnetization coefficient (X) of non-magnetic minerals is less than 15 *10^(-6)cm³/g.

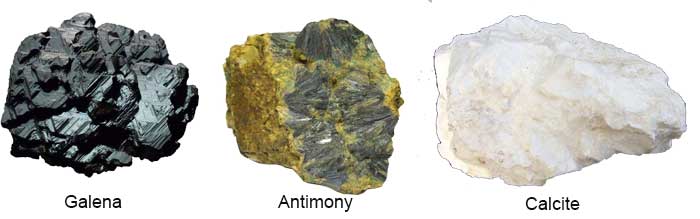

There are many kinds of non-magnetic minerals. It mainly includes: some metal minerals – Chalcopyrite, Galena, Sphalerite, Stibnite, Scheelite, Cassiterite, Gold, etc.

Most non-metallic minerals – Sulfur, Coal, Calcite, etc.

Some of these minerals are paramagnetic and some are antimagnetic. The magnetism of nonmagnetic minerals is very small. At present, the magnetic separator can not realize mineral processing, so it is called non-magnetic mineral.

NOTE: With the development of magnetic separation technology, the boundary between weak magnetic minerals and non-magnetic minerals will change. The lower limit of the magnetization coefficient of weak magnetic minerals is decreasing, which is the inevitable trend of the development of magnetic separation.

Therefore, more and more minerals can be recovered and separated by magnetic separation, and magnetic separation is a pure physical method, which will not pollute the environment, so it will become the development trend of beneficiation technology.

18 Types of Magnetic Separator Machines

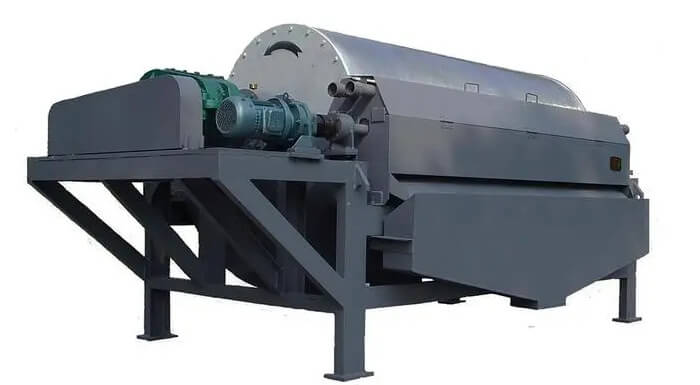

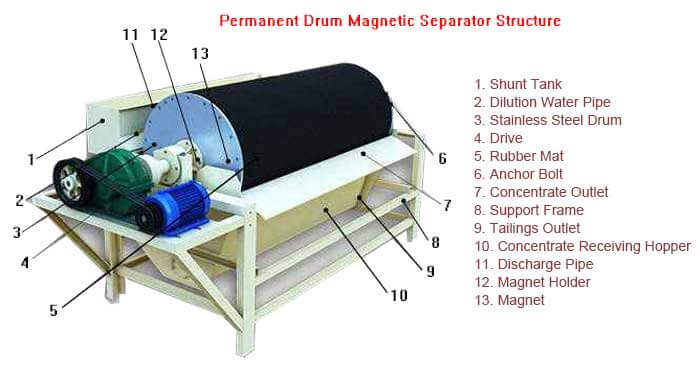

Magnetic separator machine is a kind of separation equipment which produces strong magnetic field attraction. It can remove ferromagnetic materials mixed in non-magnetic materials.

Magnetic separators are widely used in metallurgy, mining, coal preparation, power plant, ceramics, building materials, food and fodder processing industries. Common 18 types of magnetic separators are as bellow:

- Permanent Magnetic Separator

- Electromagnetic Magnetic Separator

- Single Drum Magnetic Separator

- Double Drum Magnetic Separator

- Multi Drum Magnetic Separator

- Open Circuit Magnetic Separator

- Closed Circuit Magnetic Separator

- Upper Feeder Magnetic Separator

- Lower Feeder Magnetic Separator

- Weak Magnetic Separator

- Medium Magnetic Separator

- Strong Magnetic Separator

- Drum Magnetic Separator

- Roller Magnetic Separator

- Dry Magnetic Separator

- Wet Magnetic Separator

- Plate Magnetic Separator

- Disk Magnetic Separator

How To Classify Magnetic Separators

How To Classify Magnetic Separators What is Permanent Magnetic Drum Separator | How Does It Work

What is Permanent Magnetic Drum Separator | How Does It Work Eddy Current Separator & Types | Versus Electrostatic Separation

Eddy Current Separator & Types | Versus Electrostatic Separation How To Classify Cement ?

How To Classify Cement ?

Dear Sir/Madam

We have high amount iron ore powder 33 percent.

Please tell me best method for resolutio that.

Best Regard

Thanks

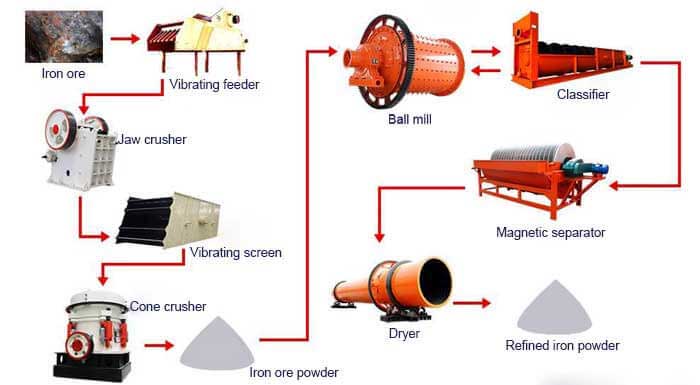

Hello Reza Jadidoleslam,

Share a general and simple iron ore magnetic separation process: