Quartz Sand Applications in 10 Different Industrial Fields

Quartz sand is an important raw material for nearly 100 kinds of industrial products, such as glass, electronics and electrical appliances, optical fiber semiconductors, water treatment, mechanical casting, artificial quartz stone, daily ceramics, metallurgy, superhard materials, chemical industry, cement, functional fillers, oil drilling and so on.

The quality requirements of quartz products are also different in different industrial applications. In this article, we will learn how quartz sand is used in 10 different industrial fields:

1. Glass Industry

Quartz is the main raw material of glass industry, and its quality requirements lay in 3 aspects: chemical composition, stability and particle size.

2. Electronic & Electrical Industries

In the electronic and electrical industry, quartz powder (silicon powder) is an important functional filler for epoxy resin castables, filling materials, plastic sealing materials, packaging materials, engineering plastics, coatings, silicone rubber and electrode protective coatings. At present, the highest filling rate of spherical silicon powder in EMC has reached > 90%.

3. High-end Quartz Material Industry

High-purity quartz sand is an important raw material for producing high-purity quartz tubes, quartz rods, quartz bars, quartz plates, quartz crucibles and other high-end quartz products. Optical communications, semiconductors, special materials usually require the purity of quartz sand > 99.998%, the impurities content < 22ppm, and the single alkali metals (potassium, sodium, lithium) content is less than 1ppm.

4. Water Treatment Industry

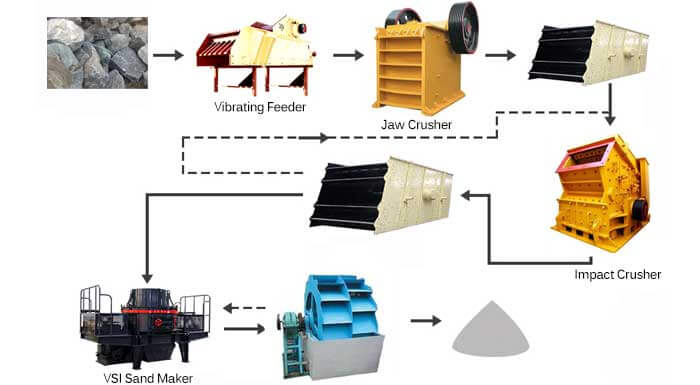

Quartz Filter: Quartz sand filter material is made of natural quartz ore as raw material and processed by crushing, washing, screening and other processes. it is the most widely used water purification material in water treatment industry

Quartz sand is the earliest and widely used filter material for wastewater treatment. The particle size and thickness of quartz sand filter media play an important role in the filtration performance.

5. Mechanical Foundry

In foundry casting process, silica sand (quartz sand) is the most widely used and largest amount of foundry sand. According to the different mining and processing methods, it can be divided into natural silica sand and artificial silica sand, such as water washed sand and scrubbed sand etc.

Casting Sand: The quality of silica sand directly affects the quality of castings, production efficiency and enterprise cost

6. Artificial Quartz Stone Plate

Artificial quartz is composed of more than 90% natural quartz sand (powder) of aggregate, about 10% of pigments, resins and other additives that regulate adhesion and curing, etc. Such as vein ore quartz, sand (rock) ore quartz and weathered quartzs all can be used as raw materials for artificial quartz.

7. Domestic Ceramics

As the raw material of ceramics, quartz has non-plasticity. Quartz transformed into mullite crystals under high temperature and makes porcelain has high mechanical strength and chemical stability. Quartz can increase the translucency of the green body, so it is a good raw material for preparing white glaze.

Ceramics: The main raw materials of ceramics are high purity quartz sand, which can be used in glazes, blanks, daily ceramics, sanitary ware, household decoration tiles, floor tiles, quartz kitchen countertops, cabinets, etc.

8. Metallurgical Industry

In the metallurgical industry, quartz can be used to make refractories (silica brick), smelting siliceous alloys (ferrosilicon, silicomanganese, silicochromium) or as fluxes. Those with high silica content can be used as raw materials for industrial silicon production.

Ferrosilicon: Ferrosilicon is an iron-silicon alloy made from coke, steel shavings, quartz (or silica) and smelted in an electric furnace

9. Super Hard Material

Industrial silicon carbide is divided into black silicon carbide and green silicon carbide. Black silicon carbide is made by high temperature smelting in resistance furnace with quartz sand, petroleum coke and high quality silica as the main raw materials. Green silicon carbide is made by high temperature smelting in resistance furnace with petroleum coke and high quality silica as main raw materials and salt as additive.

10. Chemical Industry

In the field of chemical products processing, quartz sand is the main raw material for the production of potassium silicate, sodium silicate and various forms of silicon dioxide.

Sodium Silicate: Sodium Silicate is a colorless, slightly colored translucent or transparent bulk vitreous body, used as fillers, fabric fireproofing agents and adhesives, etc.

What is Quartz Sand | How Many Types of Quartz Sand

What is Quartz Sand | How Many Types of Quartz Sand Silica Sand Washing Plant | Quartz Sand Processing

Silica Sand Washing Plant | Quartz Sand Processing VSI Sand Making Machine | Working Principle & Applications

VSI Sand Making Machine | Working Principle & Applications 5 differences between Silica Sand and regular Sand

5 differences between Silica Sand and regular Sand

Quartz mining has its own production land, so how can I contact the company that is looking for this mining location, which is located in the Oddo Shakiso district of Guji state

We can arrange any qty quartz /solica sand to the actival users.

Tenho uma grande reserva de QUARTZO BRANCO no Sul do Estado do Ceará, no Nordeste do Brasil.

Excelente acesso, muito fácil para exploração. Procuro parceiro para negócios, ou um bom cliente que tenha interesse em adquirir este produto. Posso fornecer in natura, em tamanhos de 2 gramas a peças de 1 tonelada ou mais.