Concrete Mixer Truck Specifications, Types, Structures

Concrete mixer truck(also called cement mixer) is a unit that mix the water, aggregate, sand or gravel, and cement to form concrete economically and quickly.

Concrete Mixer Truck Specifications & Types & Structures (PDF DOWNLOAD)

Concrete Mixer Truck Specifications

Other Stipulates:

1. During transportation, the concrete mixer drum rotates at the speed of 1-3 r/min. The maximum speed of the concrete mixer truck shall not exceed 50 km/h, while the maximum speed of the mixer drum shall not exceed 16 r/min.

2. The height of the hopper upper outlet should be no more than 3800mm from the ground; the feeding speed of the concrete mixer should be ≥ 2.7m³/min; and the discharging speed of the mixer should be ≥ 0.65 m³/min.

3. Water supply system: the capacity of water in the tank for cleaning the mixing drum shall be ≥ 180L, and the pressure in the tank shall be ≥ 0.4 Mpa.

4. When working, the temperature rise of hydraulic oil shall not exceed 40 ℃, and the highest temperature shall not exceed 80℃.

5. Discharge chute: It should be able to rotate 180 degrees horizontally to suit different unloading positions. In the vertical direction, it can adjust the tilt angle with the horizontal direction to adapt to different unloading height. An extended chute is arranged, and the assembly and disassembly are convenient.

Mixer Trucks Classification | Types of Mixer Trucks

(1) Types on the Basis of materials: dry mixing and wet mixing.

(2) Types on the Basis of discharge forms: front discharge type and rear discharge type. The rear discharge type is more common.

(3) According to the driving types:

- External powered diesel engine

- Take power through chassis engine

- Chassis drive is mainly 6×4, 8X4

(4) According to the mixer tank volume:

- 5-7 m: Mainly applicable to bridges, tunnels, sporadic projects that affected by the operating environment. The mixer truck is powered by an external powertrain (diesel engine).

- 8-10 m: Mainly 6 X4 chassis.

- 12-14 m: Rising in 2019, it is now moving towards 14 cubic meters or even larger.

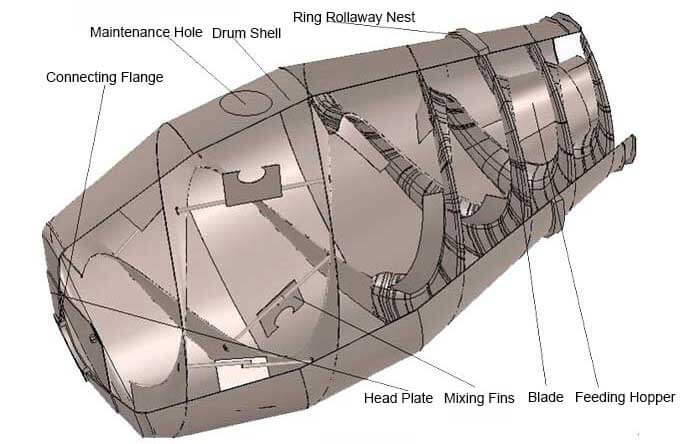

Concrete Mixer Trucks Main Structures

Concrete mixer trucks mainly consist of chassis and upper loading. It can be simply divided into 10 parts: chassis system, hydraulic transmission system, mixing tank, discharging system, cleaning system, auxiliary frame, manipulating system, bracket system, feeding system and electric system.

1. Chassis System

The main component of the mixer, the transport function of the whole concrete mixer is realized by the chassis. Chassis is usually made of type II special chassis produced by stereotyping after being installed and refitted.

2. Hydraulic Transmission System

Engine power is converted into hydraulic energy (displacement and pressure), and then output to mechanical energy (speed and torque) by motor, which provides power for the rotation of mixer drum.

3. Mixing Tank

Mixer drum is the key component of the whole mixer truck and the container for storing concrete. It plays a decisive role in preventing concrete solidification and segregation. The inner part of the tank has blades, which mainly play the role of stirring and guiding materials.

4. Discharge System

Mainly composed of main discharging trough, auxiliary discharging trough, locking rod, etc., auxiliary discharging trough can extend the length of main discharging trough.

5. Cleaning System

Cleaning system is mainly composed of pressure water tank, water gun, water pipe, valve, etc. The main function of air pressure water supply is to flush hopper after loading and unloading, flush mixer drum and unloading trough after unloading, prevent concrete from bonding.

6. Auxiliary Frame

The sub-frame of mixer is the main load-bearing part. The load during operation is almost supported by it and then transferred to the chassis. The sub-frame also alleviate bump and attenuating impact load. The whole sub-frame is composed of main beam, front support frame and back support frame.

7. Manipulating System

The manipulating system consists of controller, linkage shaft, flexible shaft and a connecting rod mechanism, which mainly controls the speed and direction of the mixer drum.

8. Bracket System

The rear part of the mixing tank is connected with the sub-frame, which mainly supports the drum body.

9. Feeding System

Mainly composed of feeding hopper and bracket. Because of the impact wear of feeding hopper, the material must be good wear resistance. The bracket mainly reducing impact force.

10. Electric System

Refers to the whole electric of the mixer, including the tail lamp, side sign lamp, Gallery lamp, cooling fan and motor.

What Is Asphalt Concrete | Types & How Is It Made

What Is Asphalt Concrete | Types & How Is It Made How To Classify Concrete [Classification, Manufacturing & Properties]

How To Classify Concrete [Classification, Manufacturing & Properties] Cement VS Concrete [8 Difference Between Cement and Concrete]

Cement VS Concrete [8 Difference Between Cement and Concrete] Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications]

Autoclaved Aerated Concrete [Definition, Types, Benefits, Applications]

I am very interested to buy this one through loan. How can I do?

Please provide the price of the concrete mixer truck

thank you for your inquiry concrete mixer truck

Hello, we are mainly manufacturers of mixer machine, concrete mixers truck and concrete pumps.

We hope to become your new supplier. Would you like our product catalogue?

Best regards!

Viny

Mixer tank