Filter Cloth Types and How To Select Filter Press Cloth

Filter Cloth Types and How To Select Filter Press Cloth [PDF DOWNLOAD]

Common Types of Filter Cloth for Filter Press

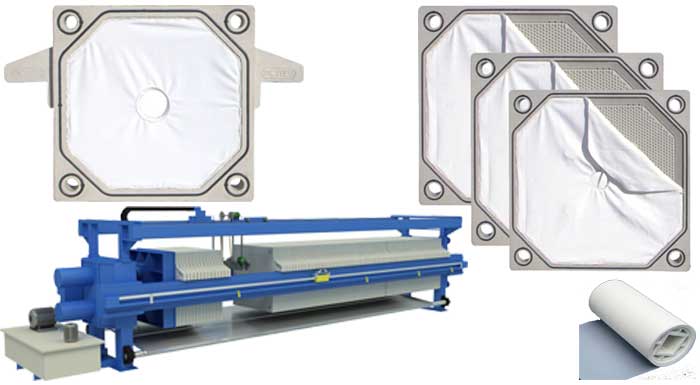

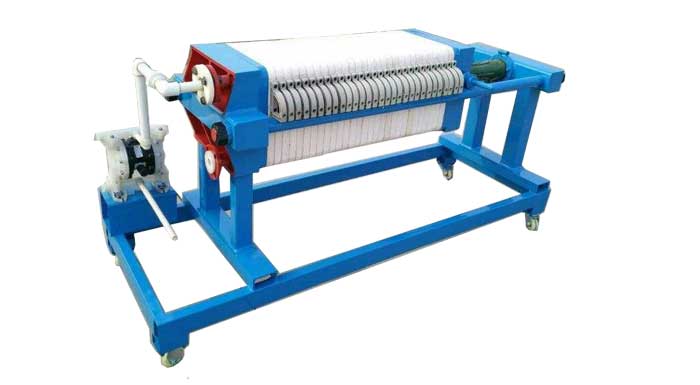

Filter cloths are a important ingredient of the filter press. Choose the right filter cloth will help you get drier filter cakes, optimal filter cake release and longer service life, which will derectly improve the filter press working efficiency and reduce maintenance costs.

Filter Cloth Selection on basis of Materials

(1.) Vinylon Filter Cloth

The chemical name of vinylon filter cloth is polyvinyl alcohol. Its strength is lower than that of polyester, its elasticity is poor, the shape retention of fabric is poor, but its wear resistance is better, and its durability is 1-2 times that of pure cotton.

Advantages: it can withstand the action of strong alkali, and has good hygroscopicity. It is easy to combine with rubber. It is a good material for rubber industry.

Disadvantages: low temperature resistance, shrinkage when the temperature reaches 100 ℃, and acid resistance.

Application: used in the factory or rubber industry with strong alkaline material.

(2.) Polyester Filter Cloth

Polyester filter cloth is resistant to high temperature, it has the special advantages of common felt filter cloth, and it has very good wear resistance. It has a high cost performance and becomes the most used filter cloth in felt filter material.

Advantages: acid resistance, weak alkali resistance, wear resistance, corrosion resistance, good recovery

Disadvantages: poor peeling and air permeability

Application: pharmaceutical, sugar, food, chemical, metallurgical, industrial filter press, centrifuge, etc.

(3.) Nylon filter cloth

According to the test, the wear resistance of nylon fiber is 10 times of that of cotton fiber and 50 times of that of viscose, which ranks first in many kinds of fibers. Therefore, nylon filter cloth is a high wear-resistant filter cloth.

Advantages: nylon filter cloth is resistant to strong alkali, weak acid and wear.

Disadvantages: nylon filter cloth is not light resistant, easy to change color and brittle, so it is not suitable for long-term exposure to the sun.

Application: rubber, ceramics, pharmaceutical, food, metallurgy, etc.

(4.) Polypropylene Filter Cloth

Long polypropylene fiber filter cloth has smooth surface and good air permeability;short polypropylene fiber filter cloth has wool surface, and the effect of powder filtration and pressure filtration is better than that of long fiber.

Advantages: polypropylene filter cloth has good acid resistance, alkali resistance, wear resistance, good conductivity, slightly better recovery than polyester.

Disadvantages: poor corrosion resistance.

Application: chemical, ceramic, pharmaceutical, smelting, manufacturing, beneficiation as filter cloth.

[Comparison of 6 Filter Cloths Materials]

Filter Cloth Selection on Basis of Yarn Types

(i.) Monofilament Yarn

Monofilament yarn is a single continuous filament made of synthetic fiber. The characteristics of the filter cloth woven from monofilament yarn are not easy to be blocked, good cake release and particle retention.

(ii.) Multifilament Yarn

Multifilament yarn is made of two or more continuous monofilament yarns. The characteristics of the filter cloth woven from this kind of yarn are high tensile strength, good cake release and particle retention.

(iii.) Spun Yarn

Staple (spun) yarn is to twist natural or synthetic short fiber into a continuous fiber thread. The characteristics of weaving filter cloth from this thread are good particle retention and excellent sealing performance.

[Comparison of 3 Yarn Types]

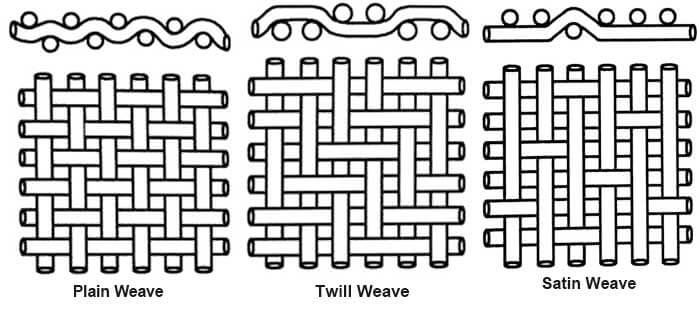

Filter Cloth Selection on Basis of Weave Patterns

(I.)Plain Weave

Plain weave is the simplest, the lowest cost and the most common weave in the fabric. A complete plain weave cycle can be formed by using two warp and two weft threads. There are many plain weave points with low porosity, but the relative position is stable. Because of the poor permeability of plain weave, plain weave filter cloth is rarely used at high filtration rate.

(II.)Twill Weave

The twill structure is made up of more than three consecutive warp and weft structures. There are oblique lines on the cloth surface. The filter bag is mostly twill. The twill weaving points are less than the plain lines. The porosity is larger and the permeability is better, so the filter cake release efficiency will be higher than the plain lines.

(III.)Satin Weave

Satin weave is made of more than 5 consecutive warp and weft threads. The basic feature of this kind of weave is that the weaving points are not continuous. There are many warp or weft threads floating on the cloth surface, which is conducive to dust stripping. The weaving points of satin weave are less than plain and twill, with the best air permeability, but there are more yarns floating on the fabric surface, which is easy to be damaged.

[Comparison of 3 Weave Patterns]

How To Select Filter Press Cloth

In order to adapt to different filtrates, we divide the filter cloth into various materials, so we suggest that you choose the filter cloth according to the filtrate:

1. Filtrate Acidity and Alkalinity: Select the appropriate type of filter cloth according to different acidity and alkalinity. Polyester filter cloth has the strongest acid resistance and vinylon filter cloth has the strongest alkali resistance. Polypropylene filter cloth is both acid and alkali resistant.

2. Filter Material Temperature: The temperature is a major factor affecting the working efficiency of filter press cloths. The polyester filter cloth is most temperature resistant.

3. Filter Cake Release: The release efficiency of filter cake directly affects the working efficiency of filter press equipment. The surface of the filter cake is smooth and non sticky, and the filtrate will quickly leach out of the filter cloth, with high filtration efficiency. In this case, it is necessary to choose single silk filter cloth or satin filter cloth.

4. Filter Cake Shape: Consider the wear resistance of filter cloth according to whether the particles are uniform and whether the shape is hard. The polyester filter cloth and nylon filter cloth is best wear resistance.

When To Change Your Filter Cloth

The filter press is affected by acid and alkali corrosion, mechanical wear and the aging of the filter cloth in the process of use, which results in the filter cloth of the filter press has a life limit. Generally, the service life of filter cloth of filter press used in ceramic industry and coal industry is about 3 to 5 months. The service life of filter press cloth used in sludge treatment will be relatively longer.

To know when to change your filter cloth, please pay attention to the release of the mud cake. If the mud cake does not agglomerate normally, the filter cloth may has been damaged. Filter cloth should be replaced in time to prevent affecting the treatment effect and subsequent processes.

Learn More About Filter Press (45 Filter Press Terminology)

Learn More About Filter Press (45 Filter Press Terminology) How To Select The Feed Pump of Filter Press

How To Select The Feed Pump of Filter Press Filter Press Breakdowns And How To Repair

Filter Press Breakdowns And How To Repair How To Choose A Suitable Filter Bag for your Bag Filter

How To Choose A Suitable Filter Bag for your Bag Filter

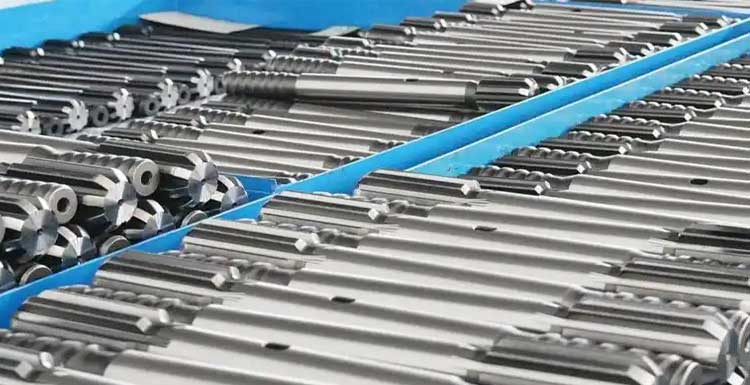

![How To Solve Drill Rod Jamming Faults [ Top 6 Tips ] How To Solve Drill Rod Jamming Faults [ Top 6 Tips ]](https://www.beidoou.com/wp-content/uploads/2025/06/Drill-Rods.jpg)

Good Day!

Kindly send your best prices for following:

FILTER CLOTH : SINGLE PANEL 84″ X 240″

EXXON MOBIL TYPE : TB-3 FOR ROTARY DRUM DE-WAXING FILTER 214-RF4

QUANTITY: 08 NO.

FILTER CLOTH:SINGLE PANEL 63-3/4″ X 248″

EXXON MOBIL TYPE : TB-3 FOR ROTARY DRUM DE-WAXING FILTER 214-RF1,RF2,RF3

QUANTITY: 30 NO.

I would like to inform you which filter press fabrics you recommend and have for the inert sludge filtration and dehydration process in the construction aggregates industry.

give me references and permeability value, size and quote.

Regards,

Luis Londono

can you tell me in complete detail about how to select filter press fabric