Become More Professional In Dewatering Screen

How Many Types of Dewatering Screen

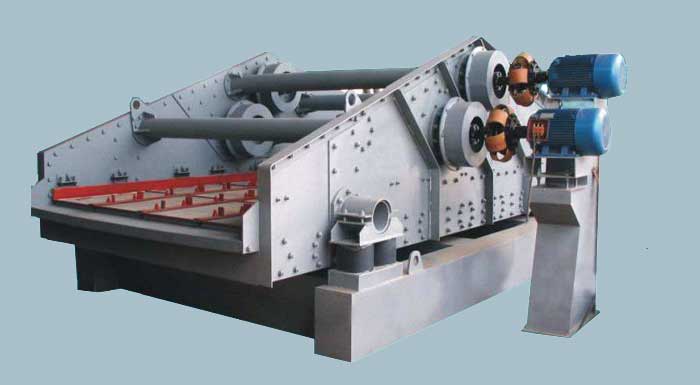

Dewatering screen has many applications, mainly including dewatering, desliming, degritting and washing. Dewatering screens can be used for sand washing in sand and gravel plant, slime recovery in coal preparation plant, dry discharge of tailings in concentrator, etc., so it is also called sand and gravel dewatering screen, mine dewatering screen, slime dewatering screen, tailings dewatering screen, high frequency dewatering screen and so on.

Sand/Gravel Dewatering Screen VS Tailings Dewatering Screen

Although the two all belongs to the dewatering equipments, the structure of the dewatering screen is still different when acting on different materials.

For example, the dewatering screens commonly used in sand washing plant are different from the tailing dewatering screens that used in concentrators. The former is mainly used in wet sand production line, matched with sand washing machine. Tailings dewatering screen is mainly used for coal preparation, the configuration of tailing dewatering screen is much higher, and the processing capacity is also bigger.

Can Dewatering Screen Be Used Alone

Dewatering screen can be used alone when acting on some materials with low mud content, and there is no need for sand washing machine.

For example, when using sand washing machine to deal with quartz sand with low mud content, it not only consumes energy but also has poor effect. The most important thing is that the investment cost of sand washing machine is much higher than that of dewatering screen.

Are Vulnerable Parts Replaced Frequently

There are little vulnerable parts of dewatering screen, such as screen mesh, screen plate, vibrating motor etc. The replacement frequency needs to be determined according to the actual field situation of the users, and the difference is bigger.

What’s The Common Sand Washing Equipments

There are three commonly used sand washing equipments: screw sand washer, wheel sand washer and vibrating dewatering screen. Which are mainly used to wash, classify and dewater materials in sand and gravel plant, mining, building materials, chemical industry, concrete mixing station and other industries.

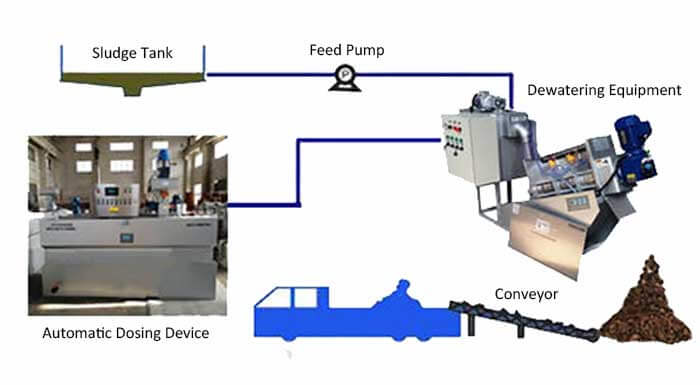

Why Sand Washer Equipped With Dewatering Screen

Sand washed by sand washer is not very clean, which contains a large amount of mud and is too wet (high water content), that does not meet the standard of sand and mud content. Therefore, it is necessary to configure a dewatering screen.

The sand washed by the sand washer is then cleaned by dewatering screen for secondary cleaning, hydraulic classification, desliming and dehydration. The mud content can be reduced to < 0.7%, and the qualified particle size ratio can be achieved.

Coal Dewatering Screen | Working Principle | Features

Coal Dewatering Screen | Working Principle | Features Dewatering Screens | Why & How To Choose Dewatering Screens

Dewatering Screens | Why & How To Choose Dewatering Screens Dewatering Equipments for Mineral & Sludge

Dewatering Equipments for Mineral & Sludge Sand Washer Machine In Malaysia

Sand Washer Machine In Malaysia