Ball Mill | Working Principle | Ball Mill Types

What is Ball Mill?

Ball mill is a common industrial grinding equipment, mainly used to grind raw materials into fine powder. It grinds the raw materials into the desired fine powder by placing abrasives and raw materials inside a rotating cylinder, utilizing the force of friction and impact.

Ball mill is the key equipment for grinding crushed materials, which can be used for grinding limestone, dolomite, calcite and other ores. Its crushing ratio can range from 3 to 100, and both wet and dry grinding can be used as its abrasive methods. In addition, ball mills can grind materials into very fine particle sizes and can be quickly completed, making them the preferred choice for industrial applications. According to different applications and requirements, there are various types of ball mills.

The characteristics of ball mills are mainly reflected in the following aspects:

- Wide Applicability: Ball mills are widely used in the mineral processing industry for grinding raw materials such as iron ore, gold ore, copper ore, lead zinc ore, quartz, feldspar, kaolin, cement, ceramics, etc.

- High Fineness: By adjusting the speed and rotation angle, products with different fineness can be obtained to meet different needs.

- Energy Saving: Ball mills have lower energy consumption and lower noise, and can be equipped with dust removal equipment to reduce environmental pollution.

- Simple Structure: The structure of the ball mill is relatively simple, easy to manufacture and maintain, and also convenient for adjustment and optimization.

How Ball Mill Works

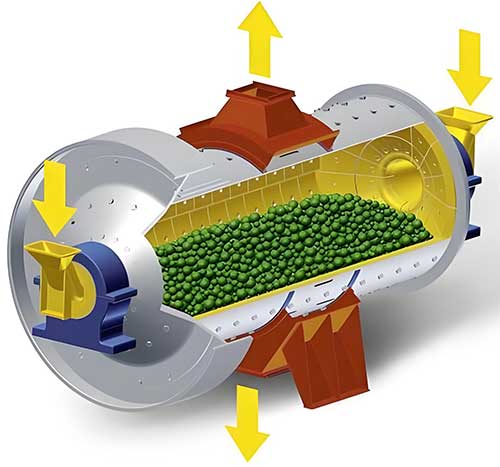

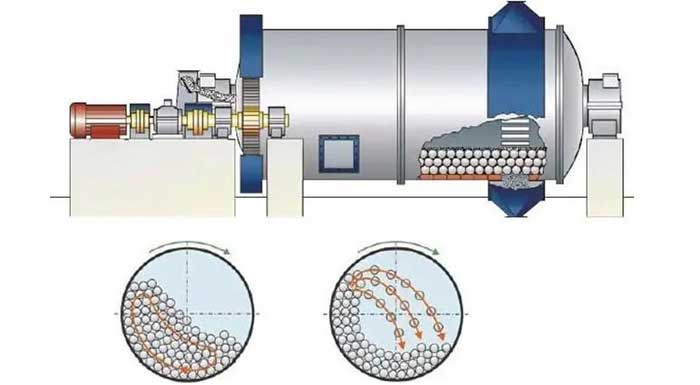

The working principle of a ball mill is mainly based on impact and wear. During its operation, the ball mill cylinder rotates at a certain speed, and the grinding medium inside the cylinder (such as steel balls, ceramic balls, etc.) rotates to a certain height under the action of centrifugal force and friction. When the gravity of these grinding media is greater than the centrifugal force, they will detach from the inner wall of the cylinder, freely fall or roll down, and have a strong impact and grinding effect on the material. At the same time, when the cylinder rotates, the sliding motion between the grinding media and between the grinding media and the inner wall of the cylinder will also have a grinding effect on the material.

Throughout the working process, the electric motor and reducer provide power to continuously rotate the ball mill cylinder. By adjusting the rotation speed and the size of the grinding medium used, the particle size of the finished product can be controlled.

Different Types of Ball Mill

(1) Types on the Basis of Cylinder

1. Short Cylinder Ball Mill: Short cylinder ball mills are mainly used for rough grinding operations or primary grinding operations. Its cylinder length L is less than twice the diameter D of the cylinder, which means L ≤ 2D. This design makes the short cylinder ball mill exhibit high efficiency in operation. In addition, short cylinder ball mills are usually single chamber structures, which is also an important factor in achieving efficient operation.

2. Medium Long Ball Mill: When the cylinder length L = 3D, it’s a medium long ball mill.

3. Long Cylinder Ball Mill: When the cylinder length L ≥ 4D, it’s a long ball mill. It is generally divided into 2-4 bins.

(2) Types on the Basis of Grinding Medium

1. Ball Mill: The grinding medium of the ball mill is mainly steel balls or steel sections, and it is widely used.

2. Rod Mill: The grinding medium is mainly steel rod, the diameter of steel rod is mostly between 50-100mm, and the grinding time is longer.

3. Gravel Mill: also known as a pebble mill, is a device used for grinding pebbles. Usually used for processing stone or ore to achieve specific particle size or shape requirements. The pebble mill has a wide range of applications in industries such as chemical, building materials, and metallurgy, and can efficiently and accurately complete grinding operations.

(3) Types on the Basis of Unloading Materials

1. Tail Discharge Mill: TThe material of the tail discharge mill is fed in from one end and fed out from the other end.

2. Intermediate Discharge Mill: The material of the intermediate discharge mill is fed into both ends of the mill and discharged from the middle of the mill barrel, equivalent to two ball mills used in parallel.

(4) Types on the Basis of Discharge Methods

1. Overflow Type: Ore discharged through hollow shaft.

2. Grid Type: Ore discharged through grid plate.

3. Peripheral Type: Ore discharged around the cylinder.

(5) Types on the Basis of Drive Mode

1. Center Drive Ball Mill: The electric motor of the central drive mill drives the hollow shaft at the discharge end of the mill through a reducer to drive the grinding body to rotate. The output shaft of the reducer is in a straight line with the centerline of the mill.

2. Edge Drive Ball Mill: The electric motor of the edge drive mill drives the large gear fixed on the discharge end cylinder through a reducer to drive the rotation of the mill cylinder.

(6) Types on the Basis of Process Characteristics

1. Wet Type Ball Mill: During the operation of a wet ball mill, materials, water, and steel balls are mixed in a certain proportion and ground inside the ball mill. This wet grinding method ensures thorough mixing and uniform grinding of materials, suitable for materials that do not change when exposed to water.

2. Dry Type Ball Mill: Dry ball mills mainly grind dry materials without the need for adding water or other liquids. Suitable for grinding dry materials, such as quartz sand, silica fume, cement clinker, etc.

(7) Types on the Basis of Cylinder Direction

1. Vertical Ball Mill: The working chamber of a vertical ball mill is vertical, and the equipment form is vertical; Vertical ball mills are usually driven by motors through reducers and supported by bearings to rotate the shaft. Due to its relatively high center of gravity, the vibration during operation is relatively small and the operation is relatively stable; Vertical ball mills are mainly suitable for mining, metallurgy, cement and other places, used for wet or dry grinding of ores, non-metallic minerals, etc;

2. Horizontal Ball Mill: The working chamber of a horizontal ball mill is horizontal, and the equipment form is horizontal. The horizontal ball mill uses an electric motor to drive the rotation of the shaft through transmission devices such as reducers, clutches, and couplings. Due to its relatively low center of gravity, the vibration during operation is relatively high. Horizontal ball mills are mainly suitable for industries such as chemical, power, ceramics, etc., and are used for dry or wet grinding of various materials.

Ball Mills vs Rod Mills | How To Choose Ball Mill or Rod Mill

Ball Mills vs Rod Mills | How To Choose Ball Mill or Rod Mill 14 Types of Ball Mill Troubleshooting and Solutions

14 Types of Ball Mill Troubleshooting and Solutions Screw Conveyor Features | Working Principle and Types

Screw Conveyor Features | Working Principle and Types Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Top 10 Vibrating Screen Types & Working Principle [How To Choose]

Price on a Small ball mill?

Interested in knowing ball mills for nanocellulose production