limestone | Composition | Properties | Source | 6 Types | 10+ Uses

What is limestone

Limestone is a type of sedimentary rock, mainly composed of calcium carbonate (CaCO₃). Lime and limestone are widely used as building materials and are also important raw materials for many industries. Calcium carbonate can be directly processed into stone and fired into quicklime. However, attention should be paid to the danger in the production process. Quicklime, when absorbing moisture or adding water, becomes slaked lime, also known as hydrated lime.

There are two kinds of lime: quicklime and slaked lime. The main component of quicklime is CaO, which is generally in the form of blocks, pure white in color, and grayish or yellowish when containing impurities. The main component of slaked lime is Ca(OH)2. Slaked lime can be mixed into lime putty, lime mortar and lime sand to be used as coating materials and tile adhesives.

limestone Composition

Limestone is an aggregate of minerals, and its chemical formula is CaCO₃. The main mineral component is calcite, followed by often containing dolomite, magnesite and other carbonate minerals. In addition, there are also chalcedony, clay, pyrite, magnetite, water needle iron ore, sea greenstone, organic carbon, gypsum, anhydrite and other minerals. The pure limestone has a chemical composition close to the theoretical composition of CaCO₃, with CaO accounting for 56.04% and CO2 accounting for 43.97%.

limestone Properties

Limestone is presented as calcite microcrystals, with complex crystal shapes often appearing as partial trigonal faces and rhombs, and ranging from light gray to dark gray or off-white in appearance for a compact mass, particles, or tubercles with various pore structures.

Its hardness is 3, its density is 2.6 – 2.9, and its melting point is 825℃. It decomposes into calcium oxide and carbon dioxide between 830℃ and 1020℃. Limestone undergoes boiling and dissolution when exposed to dilute acid.

Limestone has good processability, polishing ability, and good bonding performance. It is insoluble in water and easily soluble in saturated sulfuric acid. It can react with various strong acids and form corresponding calcium salts

| Type | Density | Boiling | Melting | Bituminous | Molecular Formula | Molecular Weight |

| limestone | 2.75 g/mL at 25 °C(lit.) | 2850ºC | 825ºC | 825ºC | CaCO₃ | 100.08700 |

limestone Source

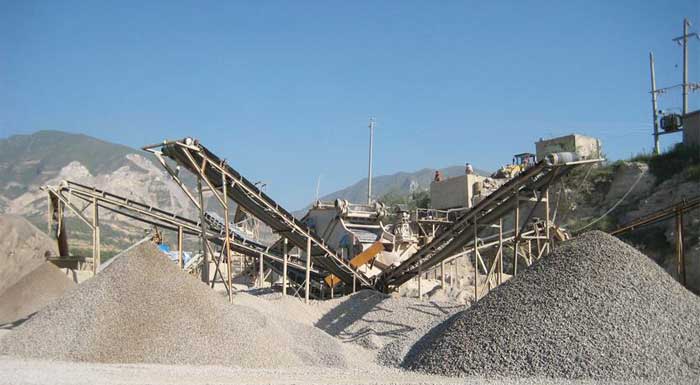

Limestone mainly originates from limestone deposits in the natural. These deposits are widely distributed on the Earth’s surface, especially in sedimentary rock areas, volcanic rock areas, and metamorphic rock areas. Limestone contains some dolomite and clay minerals, and when the clay mineral content reaches 25% to 50%, it is called mudstone. When the content of dolomite reaches 25% to 50%, it is called dolomite limestone.

Limestone is widely distributed, with uniform lithology and easy mining and processing, making it a widely used building material. Europe, Asia, North America, Africa, and Oceania all have limestone deposits.

Among them, the limestone deposits in Europe are mainly distributed in countries such as France, Germany, Italy, and Spain; the limestone deposits in Asia are mainly distributed in countries such as India, China, and Japan; the limestone deposits in North America are mainly distributed in countries such as Canada and the United States; the limestone deposits in Africa are mainly distributed in countries such as South Africa and Zimbabwe; the limestone deposits in Oceania are mainly distributed in countries such as Australia.

Limestone deposits are compressed into a composite material of organic and inorganic substances through geological processes. In the mining process, limestone can be obtained by excavating mines or extracting underground ores.

Hot 6 Types of limestone

Limestone can be divided into several main types according to its chemical composition: high-calcium limestone, low-calcium limestone, crystal limestone, oolitic limestone, marl limestone, and chalk.

- High-Calcium limestone : It is a higher-quality limestone, mainly composed of calcium carbonate, usually containing more than 90% CaCO₃. Its color is usually white or grayish-white. High-calcium limestone is commonly used in building materials, steel furnace materials, glass manufacturing, papermaking, pharmaceutical and other industries.

- Low-Calcium limestone : The main component is calcium carbonate and some impurities, generally with a CaCO₃ content of less than 90%. The color of low-calcium limestone is mainly gray, yellow, or brown. Low-calcium limestone is often used in soil amendments, ceramic products, glass manufacturing and other industries.

- Crystal limestone : Also known as crystal grain limestone, is a type of limestone mainly composed of calcite grains (with a content greater than 50%).

- Oolitic limestone : Oolitic limestone is a type of limestone mainly composed of concretions, which is a good oil storage rock. Oolite limestone is formed in the wave activity zone or tidal channel water flow activity zone of the sea or lake where calcium carbonate is in a supersaturated state.

- Marl limestone : The main component is a double carbonate of calcium and magnesium. The color of marl limestone is mostly white, gray or green. It is mainly used in cement, ceramics, papermaking, plastics, paints and other industries.

- Chalk: It is a carbonate rock containing a large amount of alumina and silicon. It is usually white or light gray. Chalk is used in papermaking, chemicals, food additives, etc.

10+ Uses of limestone

1. Cement Industry

Limestone is the main raw material of cement, accounting for 70-90% of the raw material composition. The ingredients include clay based raw materials, siliceous raw materials, and iron aluminum based raw materials.

2. Plastic Industry

Calcium carbonate is the most widely used and widely used inorganic mineral powder material. As a commonly used powder material for plastics, calcium carbonate has many advantages that other powder materials do not have, such as high whiteness, easy surface organic treatment, light wear on processing equipment and molds, good molding and processing fluidity, and abundant resources and low prices. It has become the preferred inorganic mineral powder material in the plastic processing industry.

3. Rubber Industry

For rubber, calcium carbonate is the third largest reinforcing filler after carbon black and white carbon black, with characteristics such as low toxicity, low price, and good reinforcing effect.

4. Ceramic Industry

The amount of limestone used in ceramic tiles ranges from 5-15%. In ceramic body glaze, the main function is to act as a flux, which can increase the hardness and wear resistance of the glaze when used in the glaze; Increase the corrosion resistance of glaze; Reduce the high-temperature viscosity of glaze and increase the glossiness of glaze.

5. Paint Industry

Heavy calcium carbonate is the first filler in the world’s paint industry. It is not only affordable, but also can significantly reduce the production cost of coatings. Heavy calcium carbonate as a functional filler can affect many properties of coatings, such as changing the mechanical strength of the coating, improving the water resistance and powder resistance of the coating, etc.

6. Paper Industry

Calcium carbonate is one of the main inorganic chemical raw materials in the papermaking industry. Calcium carbonate used as a filler for papermaking and as a pigment for paper coating can be classified into two categories: natural calcium carbonate (GL) produced by grinding limestone, and synthetic products produced by chemical precipitation – precipitated calcium carbonate (PCC).

The purpose of adding fillers in papermaking is to improve the opacity and brightness of the paper, improve the smoothness and uniformity of the paper, increase the softness of the paper, and reduce the moisture absorption and deformation of the paper. For printing paper, the addition of fillers enhances the ink absorption and printability of the paper. Adding fillers to a larger extent is also beneficial for reducing paper costs.

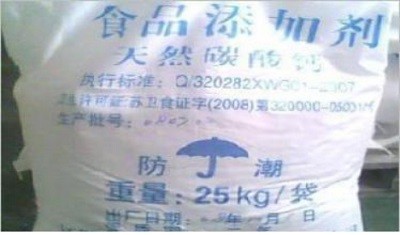

7. Food Industry

Pure mineral calcium carbonate can remove harmful substances such as heavy metal ions from minerals through various process methods to prepare relatively pure calcium carbonate as an additive in various foods.

Calcium carbonate can be used as an additive, supplement, solidifying agent, anti caking agent, yeast sugar additive, calcium supplement and modifier in food. In some foods, it can also be used as a leavening agent and fermenting agent to reduce fermentation time.

8. Pharmaceutical Industry

In the prevention and treatment of osteoporosis and other related diseases, calcium carbonate is widely used due to its high calcium content, low cost, no side effects, and the best cost-effectiveness ratio. Although there are over a dozen types of calcium salts used as calcium supplements, calcium carbonate formulations are the most widely used, calcium rich, effective, and cost-effective calcium supplements.

9. Agriculture

Quicklime can be configured as Bordeaux liquid, lime sulfur agent, and other pesticides; Hydrated lime can change the acidity and alkalinity of soil, improve the internal composition of soil, supplement calcium in soil, and lime slurry can be used to paint tree trunks and protect trees.

10. Metallurgical Industry

Limestone is used in the metallurgical industry to produce quicklime, which can be used as a slag making agent to remove harmful impurities in the steel smelting process.

Other Industry

Calcium carbonate can be used as a friction agent for toothpaste and an additive for animal feed; Calcium carbonate is also used in printing inks, putty, waxes, and adhesives, mostly as a filling material to increase volume and reduce costs.

The application of limestone in the field of chemical manufacturing will also continue to increase. Limestone can be used to manufacture various chemicals, such as bleaches, pesticides, etc. In the future, with the continuous development of chemical manufacturing, the application prospects of limestone will be even broader.

What is Granite [Composition, Properties, Types, Uses]

What is Granite [Composition, Properties, Types, Uses] 1000T/H Limestone Aggregate Production Line

1000T/H Limestone Aggregate Production Line What is Tungsten [Applications, Properties, Types, Distribution]

What is Tungsten [Applications, Properties, Types, Distribution] 10+ Rock Types That Can be Used As Building Materials

10+ Rock Types That Can be Used As Building Materials