Screw Conveyor Features | Working Principle and Types

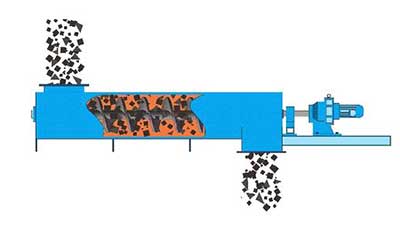

The screw conveyor is composed of driving devices, spiral bodies, bearings, machine slots, and other parts. The driving device of the screw conveyor can be installed on the right or left side depending on the installation method.

The spiral body of a screw conveyor is mainly composed of a spiral shaft and spiral blades, which are the main components that drive materials in the screw conveyor. The machine slot provides a carrier for materials and spiral bodies, facilitating the passage of materials.

Screw Conveyors Features:

- Simple Structure: The screw conveyor has a relatively simple structure, mainly composed of motors, screw shafts, and screw blades, making it easy to manufacture and maintain.

- Good Sealing Performance: Due to the good sealing performance of the screw conveyor, it can prevent materials from scattering or flying during the conveying process, reducing material loss and pollution.

- Easy to Operate: The screw conveyor is easy to operate and can be used to transport materials by controlling the motor, making it easy to master.

- Easy Maintenance: The components of the screw conveyor are relatively simple, making maintenance easier and reducing maintenance costs.

- Convenient Closed Transportation: Screw conveyors can adapt to various types of materials and can be transported with different equipment, such as closed belt conveyors, bucket elevators, etc., to facilitate closed transportation.

Screw Conveyor Working Principle

The main components of the screw conveyor include: driving device, end bearing seat, screw shaft, screw blade, end feeding port, middle feeding port, intermediate bearing seat, head bearing seat, middle discharge port, head discharge port, machine slot etc.

When screw conveyor works, the screw shaft rotates, and the material moves forward along the trough bottom of the conveyor under the push of the blade. Because of the gravity of the material and the friction between the material and the groove wall, the material does not rotate with the blade of the screw conveyor. The transportation of materials in the conveyor is a kind of taxiing.

Top 5 Types of Screw Conveyor

1. Vertical Screw Conveyor

The rotational speed of the screw body of the vertical screw conveyor is higher than that of the ordinary screw conveyor. under the action of centrifugal force, there is a friction between the conveying material and the casing, which prevents the material from rotating with the screw blade and overcomes the falling gravity of the materials. As a result, the vertical transportation of materials is realized.

The vertical screw conveyor has the advantages of small conveying capacity, small conveying height, high rotational speed and high energy consumption. It is especially suitable for conveying powdered granular materials with good fluidity, which is mainly used to lift materials, and the lifting height is generally ≤ 8m.

2. Horizontal Screw Conveyor

When the material is added to the fixed machine slot, due to the gravity of the material and the friction between the machine slot and the machine slot, the material accumulated in the lower part of the machine slot does not rotate with the spiral body, but only moves forward driven by the rotating spiral blade.

The horizontal screw conveyor is convenient for multi-point loading and unloading, and mixing, stirring or cooling can be completed at the same time in the conveying process. It is suitable for continuous and uniform transportation of loose materials with horizontal or small inclination angle, the working environment temperature is -20—+40℃, and the conveying material temperature is -20—+80℃.

The rotational speed of the horizontal screw conveyor is lower than that of the vertical conveyor, and the conveying distance is ≤ 70m.

3. Shaftless Screw Conveyor

Compared with the traditional shaft screw conveyor, the shaftless screw conveyor adopts the design of no central shaft, which can effectively prevent the influence of clogging and winding, and is suitable for conveying ribbon, loose, sticky and easy-to-winding materials. the whole conveying process is carried out in a closed conveyer, the material will not spill out and avoid secondary pollution.

The shaftless screw conveyor can be transported horizontally or in the range of 25 °.

4. Inclined Screw Conveyor

Inclined screw conveyor is a non-technical fixed type, so it is also known as mobile screw conveyor, the tilt angle is generally not more than 90 °, different screw conveyors, the corresponding angle is also different:

- Shaft screw conveyor: the inclination angle is about 45 °.

- Shaftless screw conveyor: inclination < 30 °.

Tips: for the materials with poor fluidity, the tilt angle can reach 50 °, but when the materials are transported by inclined screw conveyor, it is necessary to exert certain pressure on the feed port.

5. Bendable Screw Conveyor

The screw shaft of the bendable screw conveyor is bendable , so the conveying line can be arranged according to the space curve according to the need. This screw conveyor can be used not only for straight-line conveying but also for bending conveying, and this high degree of flexibility makes it very convenient for users to arrange all kinds of equipment.

A single bendable screw conveyor can transport materials with a vertical height of up to 10 meters and a horizontal distance of up to 25 meters. If necessary, multiple conveyors can be connected in series, which can be transported farther and higher distance.

8 Tips Help To Choose A Suitable Screw Conveyor

8 Tips Help To Choose A Suitable Screw Conveyor Spiral Chute | Working Principle | Features | Specification

Spiral Chute | Working Principle | Features | Specification Conveyor Belt Working Principle & Application

Conveyor Belt Working Principle & Application Cement Rotary Kiln | Structure & Working Principle | Types | Features

Cement Rotary Kiln | Structure & Working Principle | Types | Features

We need Screw Conveyor for Chocolates candy transferring purpose.

Regards

Dhananjay

It is very brief explanation.

One thing that I am asking is pleas add animation.