Fines Recovery Units: 9 Tips Improve Recovery Rate

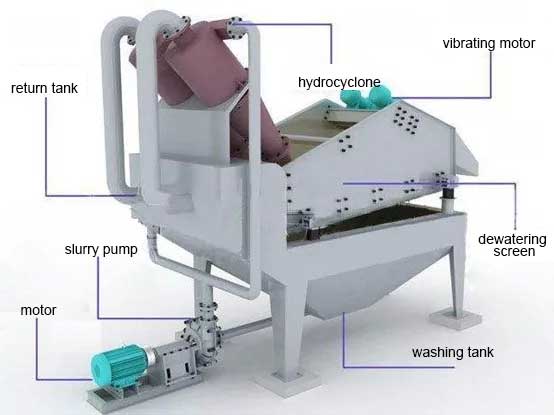

The main function of fines recovery units are to clean, dehydrate and classify sand and gravel. They can recover a large amount of fines lost by washing plants in traditional sand making industry, improve economic benefits, and reduce the treatment cost of tailings and the pollution and damage caused by the loss of fines to the environment.

In addition to the price of fines recovery units, users are more concerned about the recovery rate and effection of washing plants, because it directly affects the profits and costs of enterprises. So what are the factors that affect the recovery rate and how to improve?

1. Material Crushing Degree

Before the material enters the fines recovery unit, it is necessary for the operator to check the size of the material. If the size of the feed grain changes in production, it will immediately be reflected in the recovery stage. Ultimately, the finer the crushing particle size, the better.

2. Hardness of Material

Fines recovery unit is suitable for processing ores with Mohs hardness less than 9, so customers must pay attention to this point when choosing and purchasing. For ores with high hardness, fines recovery unit can also work, but it will accelerate the wear of vulnerable parts and affect the fineness of sand production.

3. Blade Wear of Separator

When the blade is worn, the amount of sand recovered will be reduced and the fineness become thicker. If the blade is worn seriously, the life of the separator will be affected. Therefore, the worn blades should be inspected and replaced in time(refer to: How To Fix The Breakdowns).

4. Screen Damage or Bolt Loosening

If the recovery of fine sand is obviously reduced or a small amount of sand leakage is found in operation, it is necessary to check whether the screen is broken or the bolts are loosened. In view of this situation, its treatment method is to change the screen or fasten the bolt.

When the screen is wearied seriously, it will lead to break of screen, which will decrease fine sand recovery rate. Therefore, operators must check the screen regularly in time, and replace the screen in time.

5. Processing Capacity

When purchasing fines recovery units, users should pay attention to whether the power of the equipment is equal to the capacity of their own gravel plant. If your gravel plant discharges more waste water every day than the recovery units do, of course, you can’t do that.

6. Material Density

The fines recovery units can recover the fine sand in the sand-water mixture. If the density of the sand-water mixture is too high or too low, it can not really achieve the recovery effect of the recovery machine.

7. Equipment Elements

Equipment elements have a certain impacts on fines recovery units. For example, the recovery rate of dewatering type recovery units are much higher than that of traditional equipemnts.

8. Operational Specifications

Operating factors should affect the recovery rate. For example, in closed-circuit grinding, when the sand return ratio is too large and exceeds the normal processing capacity of fines recovery units, the phenomenon of “run-out” will occur, and if the sand return ratio is too small or there is no sand return, it is easy to form a destructive scene. Therefore, uniform and stable ore feeding is required.

9. Ore Properties

The composition and physical properties of the ore have a great influence on the recovery rate. For example, when the ore size is coarse and the structure is loose, brittle and soft, it is easy to grind. It is difficult to recover minerals with finer size, finer structure and higher hardness.

Traditional artificial sand making mostly adopts the wet process. No matter what type of sand washing machine is used, the loss of fine sand is serious, and some even more than 20%.

Fines recovery units can solve the fine sand loss very well, so it is often used to extract fine sand, collect and separate sediment after sand washing machine, so as to improve the quality of machine-made sand.

Fines Recovery Plants | How To Fix The Breakdowns

Fines Recovery Plants | How To Fix The Breakdowns 11 Tips Help To Improve Your Bag Filter

11 Tips Help To Improve Your Bag Filter How To Improve Screening Efficiency Of Vibrating Screens

How To Improve Screening Efficiency Of Vibrating Screens How to improve The Excavator Bucket Teeth Service Life

How to improve The Excavator Bucket Teeth Service Life