What Is Bag Filter | Bag Filter Types | How To Choose A Right Bag Filter

What Is Bag Filter

A Bag filter, also known as fabric filter or baghouse, is a filter type dust removal equipment based on filtration principle, which uses organic fiber or inorganic fiber filter cloth to filter out the dust in the gas.

A bag filter is mainly composed of dust hopper, air duct, filter chamber (middle and lower box), cleaning room, filter bag and frame (bag cage bone), manual air intake valve, pneumatic butterfly valve, dust removal unit, etc. For the performance of bag filters, in addition to the correct selection of the filter bag materials, the dust removal unit plays a decisive role.

[Working Principle] When working, the dusty gas enters middle box from the air inlet, the dust with large particles and large specific gravity settles down and falls into the dust hopper under gravity. When the gas containing lighter dust passes through the filter bag, the dust is blocked on the surface of the filter bag, and the gas is purified and discharged from the exhaust pipe.

The dust on the filter bags can be removed by mechanical shakers, reverse gas or pulse jet methods, so as to achieve the purpose of dust removal. The dedusting efficiency of the bag filters are inseparable from the filter materials, and the performance and quality of filter materials are directly related to the performance and service life of a bag filter.

[Application] Bag filter has simple structure and strong adaptability, and can capture all kinds of dust. The dust removal efficiency of fine dust can generally reach > 99%. If the filter material has good performance, design, manufacture and operation properly, the dust removal efficiency can even reach 99.9%.

Bag filter is suitable for the dust control and purification in furniture factory, wooden door factory, floor factory, piano factory, sanitary ware factory, calcium powder factory, cement plant, sand factory, smelter, power plant, etc.

Bag Filter Types

Bag Filter Types On Basis of Cleaning Methods

There are many forms and types of bag filters, which can be classified according to their different characteristics. According to the different methods of cleaning dust, bag filters can be divided into 3 types: mechanical shakers, reverse air and pulse jet.

- (1) Mechanical Shakers : This is the simplest cleaning method, which can include manual shakers, mechanical shakers and so on. Generally, the vibration distribution of the mechanical shaker bag along the axial direction is uneven, and the acceleration attenuation is faster, the length of the filter bag is generally shorter, and the filter wind speed is also smaller.

- (2) Reverse Air : Reverse air bag filter uses the valves to switch airflow and make the filter bag shrink and bulge jitter under the action of backblowing air flow to realize dust cleaning. In this way, the viscous stripping force formed by the dust cleaning air flow in the opposite direction directly peels off the dust layer; on the other hand, due to the change of the airflow direction, the filter bag produces expansion and contraction vibration, which is also conducive to the shedding of the dust.

- (3) Pulse Jet : After the compressed air is ejected at a high speed through the nozzle, the surrounding air is induced to be sprayed into the filter bag in a very short time, resulting in rapid expansion and contraction of the filter bag. On the one hand, the peeling off of the dust layer is with the help of the peeling force of the injection air flow to the dust layer, on the other hand, it depends on the reverse acceleration formed by the expansion filter bag in the retraction process to shake off the dust. Pulse jet type cleaning method has many advantages, and the pulse jet bag filter has gradually become one of the most important dust removal devices.

Bag Filter Types On Basis of Filter Direction

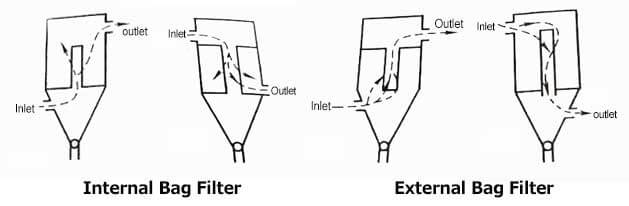

According to the filtering direction, it can be divided into two types: internal bag filter and external bag filter.

- Internal Bag Filter The dusty air flows from the inside of the filter bag to the outside, and the dust is deposited on the inner surface of the filter bag; the advantage is that the outside of the filter bag is clean gas, which is easy to overhaul and change the bag, or even can be overhauled without shutdown.

- External Bag Filter The dusty air flows from the outside of the filter bag to the inside, and the dust is deposited on the outer surface of the filter bag, and the supporting skeleton should be set up in the filter bag, so the filter wear is large.

Bag Filter Types On Basis of Filter Bag Shapes

According to the shapes of the filter bag, the bag filters are divided into 4 types: circular bag filter, flat bag filter, double-layer bag filter and diamond bag filter.

How To Choose A Right Bag Filter

In view of the dusty gas produced under different production conditions, it is necessary to select a suitable type of bag filter for purification treatment, so as to achieve the best purification effect. If the filter capacity is too large, it will cost much and cause waste, if the equipment is too small, it will affect production and can not meet the requirements of environmental protection. When choosing a right bag filter you need to consider the following 7 factors:

1. Dusty Gas Temperature

The temperature of dusty gas is the main basis for the selection of bag filters. When the gas temperature is too high, the filter bag will burn out and deform. For high temperature gas, it must be cooled to below the temperature that the filter material can bear; if the gas temperature is too low, dew will occur, so the gas temperature must be kept above 20℃( dew point).

2. Inlet Dust Concentration

The concentration of inlet dust is determined by the production process tech of the dust raising point. In the model selection, it is an important factor next to the treatment air volume. When the dust concentration at the inlet is too high, pre dedusting equipment shall be added.

3. Outlet Dust Concentration

The outlet dust concentration refers to the emission concentration of the bag filter, which is the same as the expression of the inlet dust concentration, outlet dust concentration is mainly determined by the local environmental protection emission requirements and user requirements. The concentration of tail gas after purification by the bag dust collector can generally reach 50g/Nm³.

4. Treatment Air Volume

The treatment air volume refers to the volume of the gas that can be purified by the deduster in a unit time. The unit is m ³/ h or Nm ³/ h. Treatment air volume is one of the main bases for the selection of bag filters.

5. Pressure loss

Pressure loss refers to the pressure drop, or resistance, of gas from the inlet to the outlet of the deduster.

6. Operating Pressure

The operating pressure of the bag filter is determined according to the static pressure value of the micro fan before and after the bag filter and its installation position, and it is also the design pressure value of the bag filter.

7. Filtration Speed (air-cloth ratio)

Filtration speed is defined as the speed at which the filter gas passes through the filter media, or the ratio of the air volume through the filter media to the area of the filter media. Filtration speed is the key factor in the selection of dust collector, which should be determined according to the properties of smoke or dust, application, dust particle size, viscosity, gas temperature, water content, dust concentration and different filter bag materials.

If the filtration speed is too high, the pressure loss will be larger, the dust removal efficiency will be reduced, and the dust filter bag will be blocked and damaged prematurely. However, increasing the filtration speed can reduce the filtration area required by the bag filter, so that a smaller filter can be used to deal with the same volume of gas.

Get the above factors, whether you have made a decision about the bag filter you want to order? As for the structure and layout of the bag filter, the specification and quantity of the filter bag, and the form and number of the pulse valve are all the matters of the bag filter manufacturers and engineers, you only need to check and accept the dust removal effect according to your requirements.

11 Tips Help To Improve Your Bag Filter

11 Tips Help To Improve Your Bag Filter How To Choose A Suitable Filter Bag for your Bag Filter

How To Choose A Suitable Filter Bag for your Bag Filter How Many Types of Filter Plates?

How Many Types of Filter Plates? Learn More About Filter Press (45 Filter Press Terminology)

Learn More About Filter Press (45 Filter Press Terminology)

RFQ 0012904 cement mergab

ok sir

Hi friend,

Our products : kinds of dust collector equipments

It can be used with all crusher equipments

We can provide ultra-low prices and design solutions for you .

when you need, free contact us

Ruby

It’s interesting to know how a bag filter helps remove dust from factories and such. I’d say that every manufacturing plant should have a baghouse system to remove harmful dust. If I owned a wood furniture plant, I’d definitely make sure that my employees are protected by investing in bag filters. I appreciate your insight on how bag filters work and their high adaptability features.

Thank you for sharing the use of bag filter