11 Common Faults of Sand Washer and Solutions

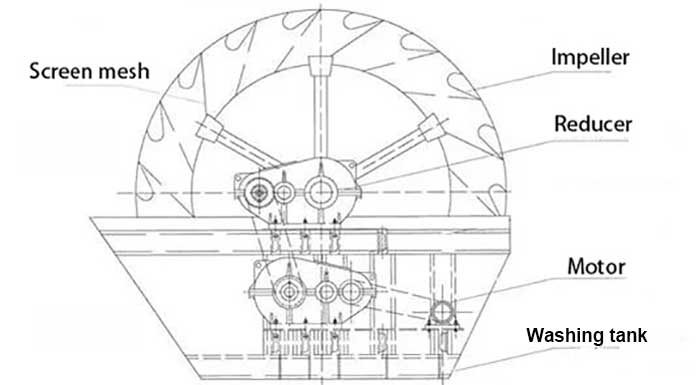

Sand washer is a piece of washing equipment for machine-made sand and natural sand. Broadly, there are two kinds of sand washing machines: spiral sand washer and wheel sand washer.

Sand washer can remove impurities that covered the surface of sand and stone, and destroy the vapor layer of sand grains, thus playing the role of efficient cleaning.

In production, the sand washers will inevitably encounter various problems:

1. The machine can’t start

Fault causes: ① insufficient voltage; ② belt slipping; ③ reducer fault; ④ motor damage.

Solutions: ① change the voltage supply; ② tighten the belt; ③ repair the reducer; ④ replace the motor operation.

2. Machine noise

Fault causes: ① bearing damage; ② gear reducer failure; ③ wheel bucket body rubbing shell.

Solutions: ① replacement of bearings; ② maintenance of reducer; ③ maintenance and adjustment of wheel bucket body.

3. Bearing temperature is too high

Fault causes: ① dirty grease; ② improper use of grease; ③ bearing damage (generally the first two reasons).

Solutions: ① Replacement of grease; ② The amount of grease must be moderate, not too much or too little; ③ replacement of bearings.

4. Splashing when washing sand

Fault causes: ① the rotational speed of the screw sand washer is too high; ② the horizontal axis of the screw disc is not fixed well.

Solutions: ① adjust the speed; ② If the speed is adjusted in place, there is still the phenomenon of turning flowers, it is necessary to fix the horizontal axis.

5. Frame Vibration

Fault causes: ① bolt loosening of connection frame; ② bolt loosening of bearing seat.

Solutions: ① fasten bolts; ② check and fasten bolts.

6. Noise in transmission part

Fault causes: ① insufficient lubrication of gears; ② varying spacing of gears.

Solutions: ① add enough grease; ② adjust the reducer foot bolt and tighten.

7. Blockage of discharge outlet

Fault causes: ① the size of sandstone in the slurry of the sand washer is too fine; ② the single feeding volume suddenly increases, resulting in silting at the outlet.

Solution: ① stop feeding, open all discharge outlets, to avoid siltation; ② washing sand washer with clean water before operation.

8. Gear damage

Fault causes: ① not timely maintenance; ② sand washer shaft and reducer low speed shaft did not reach the required parallelism.

Solutions: ① refueling according to the prescribed time; ② adjusting to meet the requirements.

9. Sand washing reduction or leakage

Fault causes: ① damage of sand screen; ② peeling of fixed bolts of sand screen.

Solutions: ① check and repair or replace the sand screen; ② fasten bolts.

10. Bearings damaged

Fault causes: ① oil breakdown or seal ring damage; ② long-term lack of maintenance and cleaning.

Solutions: ① refueling or replacing sealing rings according to regulations; ② cleaning regularly.

11. Bearing noise

Fault causes: ① bearing parts wear; ② bearing mixed with sand and other impurities.

Solutions: ① adding lubricant; ② replacing new bearings; ③ cleaning in time.

20+ Common Faults of Jaw Crusher with Solutions

20+ Common Faults of Jaw Crusher with Solutions Is Wheel Sand Washer Better Than Spiral Sand Washer ?

Is Wheel Sand Washer Better Than Spiral Sand Washer ? Types of Sand Washer

Types of Sand Washer Become a Sand Washer Expert in 3 Minutes

Become a Sand Washer Expert in 3 Minutes

Thanks for sharing your thoughts about sand washer.

Regards